+86 180 1040 9086

- Inicio

- Productos

- Acrílico

- Lámina acrílica

- Lámina acrílica transparente

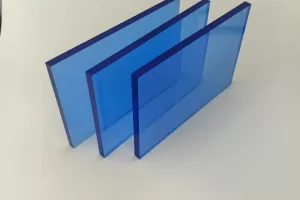

- Lámina acrílica de color

- Lámina acrílica sanitaria (bañera)

- Espejo acrílico

- Espejo acrílico

- Lámina acrílica para acuarios

- Lámina acrílica Day&Night

- Plancha acrílica ignífuga

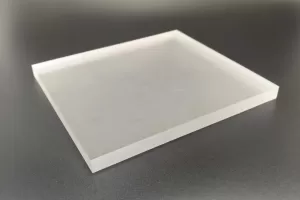

- Placa acrílica mate/esmerilada

- Hoja acrílica de purpurina/tejido

- Acrílico resistente a los impactos

- Filtro infrarrojo acrílico

- Lámina acrílica LGP

- Lámina acrílica antirruido

- Lámina acrílica para ventanas de vehículos recreativos

- Chapa acrílica de señalización

- Valla insonorizante

- Lámina acrílica especial gruesa

- Acrílico transmisor de UV

- Tubo y varilla acrílicos

- Productos acrílicos

- Lámina acrílica

- PVC

- Acrílico

- Quiénes somos

- Solución

- Blogs

- Contáctenos

DETALLES DEL BLOG

¿Cómo elegir la lámina acrílica sanitaria más perfecta para la decoración de su cuarto de baño?

A la hora de planificar la reforma de un cuarto de baño, es muy importante elegir los materiales adecuados para conseguir la integración de estética, durabilidad y funcionalidad. Entre los principales competidores de bañeras, paredes de ducha y mamparas, lámina acrílica sanitaria se utilizan. Este material especial ha revolucionado el diseño de los cuartos de baño modernos. Pero, ¿qué es y por qué se considera una opción superior? Esta completa guía profundizará en todo lo que necesita saber sobre lámina acrílica sanitaria y impermeable hoja acrílica .

¿Qué es la lámina acrílica sanitaria? Una definición

A sanitario acrílico hoja es un lámina de polímero de alto rendimiento diseñado específicamente para su uso en entornos húmedos y mojados como baños y cocinas. Está fabricado con ácido acrílico (PMMA-polimetilmetacrilato) y otros materiales compuestos, formando una superficie sólida no porosa. El término acrílico impermeable hoja se utiliza a menudo indistintamente, lo que pone de relieve su característica fundamental de ser completamente impermeable. A diferencia de materiales naturales como la piedra o la madera, no absorbe agua, lo que impide el crecimiento de moho, hongos y bacterias, y lo hace extraordinariamente higiénico.

¿Por qué elegir la placa acrílica en lugar de los materiales tradicionales? Las ventajas son enormes:

1. Excelente higiene y fácil mantenimiento: la superficie no porosa de acrílico impermeable hoja significa que no criará bacterias. La limpieza es sencilla: basta con pasar un paño con una solución suave de agua y jabón para que parezca nuevo. Se trata de una ventaja significativa con respecto a las baldosas con juntas, ya que el moho puede crecer en las juntas.

2.Durabilidad y resistencia al impacto superiores: Con una fuerza anti-impacto que es 10 veces mayor que la del vidrio ordinario (basado en pruebas de impacto estándar de la industria), estas láminas son altamente resistentes a astillarse y agrietarse. Esto las convierte en una elección segura para la residencia familiar.

3. Versatilidad estética y diseño sin fisuras: acrílico sanitario hoja pueden fabricarse en varios colores, diseños y acabados, incluidos los de alto brillo, mate e incluso texturas similares a la piedra. Pueden termoformarse en formas escultóricas sin juntas, lo que permite crear lavabos integrados, bañeras y duchas continuas sin costuras antiestéticas.

4. Ligero y fácil de instalar: Aunque su resistencia es alta, el ácido acrílico es relativamente ligero en comparación con el pesado hierro fundido o la pizarra, lo que simplifica la logística y el proceso de instalación.

5. Excelente transmisión de la luz: la transmisión de la luz es tan alta como 92% (un atributo estándar del PMMA de alta pureza), que puede hacer que los cuartos de baño más pequeños parezcan más luminosos y espaciosos, especialmente en las duchas.

Principales especificaciones técnicas y datos de rendimiento

Para garantizar la calidad, es muy importante conocer las normas técnicas. Alta calidad acrílico sanitario hoja debe cumplir las siguientes especificaciones (en consonancia con las normas de la industria del acrílico para cuartos de baño).

- Transmitancia óptica: 92%

- Densidad: 1,19 g/cm.

- Resistencia al calor (uso prolongado): -40 ° c a 90 °.

- Grado antiamarilleo: grado de resistencia a la intemperie, que garantiza la estabilidad del color a largo plazo.

- Tolerancia de espesor: 0,1 mm (para garantizar la coherencia de la fabricación).

- Tamaño máximo disponible: Hasta 3000 mm x 9000 mm, lo que permite grandes instalaciones sin juntas.

(Fuente: Norma general de la industria para la fundición de láminas de PMMA publicada por ASTM International y otras organizaciones).

Primarias aplicaciones: ¿Dónde se utiliza la lámina acrílica sanitaria?

Como su nombre indica, este material se utiliza principalmente para entornos sanitarios.

- Revestimiento de bañeras y bañeras: Puede termoformarse en formas complejas, por lo que es la opción ideal para bañeras modernas, independientes y empotradas.

- Pared de ducha y tabique: cree una valla de ducha lisa y fácil de limpiar, menos propensa a las filtraciones de agua que las paredes de baldosas de cerámica tradicionales.

- Encimeras de lavabo y lavabos integrados: Ofrecen un aspecto fluido y elegante para las encimeras de baño.

- Revestimiento mural: se utiliza como revestimiento integral, creando una sensación estética moderna minimalista sin líneas de mortero.

Preguntas y respuestas frecuentes

P: ¿Cuál es la diferencia entre la placa acrílica sanitaria y la fibra de vidrio utilizada en bañeras?

R: Aunque ambas son opciones, acrílico sanitario hoja suele considerarse una opción de alta calidad. Es más duradera, tiene más brillo, un acabado más profundo y es más resistente a astillarse y agrietarse. La fibra de vidrio puede ser más flexible, pero con el tiempo es fácil que se decolore y se amortigüe.

P: ¿Puedo reparar un arañazo profundo del tablero acrílico?

R: Sí, los arañazos leves o moderados (de 0,3 mm de profundidad) suelen poder repararse. Los métodos estándar implican el uso de un compuesto de pulido especial. Por ejemplo, un agente pulidor como AC-Polish 03 puede pulirse con un disco de pulir de lana suave a una velocidad de unas 800 revoluciones por minuto para reparar gradualmente la superficie. Un daño mayor puede requerir un rellenado y pulido profesional.

P: ¿Es seguro utilizar productos de limpieza abrasivos en un tablero acrílico resistente al agua?

R: No. Evite utilizar estropajos, polvos de limpieza o productos químicos irritantes como el quitaesmalte. Éstos pueden rayar u oscurecer la superficie de alto brillo. Utilice paños suaves y detergentes no abrasivos y neutros.

P: ¿Cuál es el radio mínimo de curvatura de una placa delgada de 5 mm de espesor?

R: Para evitar el blanqueamiento por tensión (manchas blancas en las curvas), el radio mínimo de curvatura debe ser al menos tres veces el grosor de la placa. Para una placa de 5 mm, esto significa que el radio no es inferior a 15 mm. Siempre se utiliza el proceso de termoformado, que se controla para calentar uniformemente a unos 110.

Categorías de puestos

- Blogs22

Categorías de productos

- Acrílico 19

- Lámina acrílica 17

- Lámina acrílica transparente 1

- Lámina acrílica de color 1

- Sanitario(Bañera Lámina acrílica 1

- Espejo acrílico 1

- Lámina acrílica para acuarios 1

- Lámina acrílica Day&Night 1

- Plancha acrílica ignífuga 1

- Placa acrílica mate/esmerilada 1

- Hoja acrílica de purpurina/tejido 1

- Acrílico resistente a los impactos 1

- Filtro infrarrojo acrílico 1

- Lámina acrílica LGP 1

- Lámina acrílica antirruido 0

- Lámina acrílica para ventanas de vehículos recreativos 1

- Chapa acrílica de señalización 1

- Valla insonorizante 1

- Lámina acrílica especial gruesa 1

- Acrílico transmisor de UV 1

- Tubo y varilla acrílicos 2

- Lámina acrílica 17

- PVC 2

Entradas recientes

Guía definitiva del tablero de espuma de PVC: ...

02/27/2026 Comentarios desactivados en Ultimate Guide to PVC Foam Board: Properties, Uses, and BenefitsEn qué fijarse al comprar ...

02/12/2026 Comentarios desactivados en What to Look for When Buying a High-Quality Acrylic Tube Product for Professional Use?¿Qué es una varilla acrílica y ...

02/05/2026 Comentarios desactivados en What is an acrylic rod and how do you use it? Acrylic Rod Sizes, Applications & Buying GuideGuía para principiantes: Lo que debe saber ...

01/29/2026 Comentarios desactivados en Beginner’s Guide: What You Must Know Before Buying a RV window acrylic sheetGuía para elegir el ...

01/22/2026 Comentarios desactivados en A Guide to Choosing the Right Color Acrylic Sheet for Your ProjectsSolicitar un presupuesto rápido

Olvídese de los intermediarios. Obtenga precios directos de fábrica.