+86 180 1040 9086

- Início

- Produtos

- Acrílico

- Folha de acrílico

- Folha de acrílico transparente

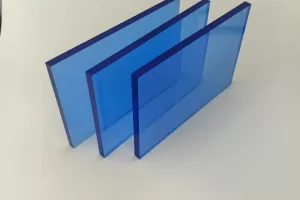

- Folha de acrílico colorida

- Folha de acrílico para sanitários (banheiras)

- Folha de espelho acrílico

- Folha de espelho acrílico

- Folha de acrílico para aquário

- Folha de acrílico para dia e noite

- Folha de acrílico resistente ao fogo

- Folha de acrílico fosco/fosco

- Folha de acrílico com brilho/tecido

- Acrílico resistente a impactos

- Filtro de infravermelhos Acrílico

- Folha de acrílico LGP

- Chapa acrílica anti-ruído

- Folha de acrílico para janelas de veículos de recreio

- Folha de acrílico para sinalização

- Vedação com barreira acústica

- Folha de acrílico espesso especial

- Acrílico transmissor de UV

- Tubo e haste de acrílico

- Produtos acrílicos

- Folha de acrílico

- PVC

- Acrílico

- Sobre nós

- Solução

- Blogues

- Contactar-nos

DETALHES DO BLOGUE

Como escolher a melhor folha de acrílico fosco para painéis LED, caixas de luz e divisórias interiores?

Ao escolher os materiais dos painéis LED, caixas de luz ou divisórias internas, a escolha da placa pode afetar significativamente o desempenho e o aspeto estético do produto final. Entre as várias opções disponíveis, chapa acrílica fosca, também vulgarmente designado por chapa acrílica mate, destaca-se pela sua combinação única de propriedades que o tornam a escolha ideal para uma vasta gama de aplicações.

O que é uma chapa acrílica mate fosca?

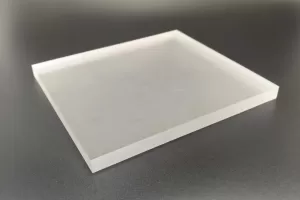

A acrílico fosco folha é um tipo de placa de PMMA (polimetilmetacrilato). Após um tratamento especial da superfície, obtém-se uma aparência fosca uniforme em ambos os lados. Este tratamento não só confere ao papel um efeito mate único, como também melhora as suas características de difusão da luz. Ao contrário do convencional placa acrílica, a placa acrílica convencional produz brilho e reflexos devido à sua superfície lisa, e o acrílico fosco folha proporciona uma elevada transmissão de luz (entre 85% e 92%), mantendo uma baixa refletividade. Isto torna-as um excelente substituto do vidro fosco, proporcionando efeitos visuais semelhantes, melhorando as propriedades mecânicas e facilitando o seu processamento. O mercado global de chapas acrílicas está a registar um crescimento constante, com uma procura crescente de variantes especializadas como chapa acrílica fosca, conforme indicado nos relatórios de estudos de mercado (fonte: Grand View Research - Acrylic Sheets Market).

Caraterísticas principais das chapas acrílicas foscas foscas.

Efeito antirreflexo

Uma das caraterísticas mais notáveis do acrílico fosco folha é o efeito antirreflexo. A refletividade da superfície destas placas é inferior ou igual a 10%, o que pode reduzir eficazmente a reflexão da luz e a fadiga visual ao máximo, tornando-as especialmente adequadas para painéis LED e caixas de luz onde o brilho pode tornar-se um problema importante.

Uniformidade de transmissão da luz

Acrílico fosco folha apresentam uma excelente uniformidade de transmissão de luz. Têm uma taxa de difusão de luz superior a 90%, o que significa que podem converter fontes de luz pontuais em luz de superfície suave e uniforme. Isto cria um ambiente de iluminação confortável e visualmente atrativo, sem sombras deslumbrantes e pontos brilhantes.

Força física

Apesar da sua aparência delicada, chapa acrílica fosca são incrivelmente fortes. Têm uma resistência ao impacto que é aproximadamente 10 vezes superior à do vidro, o que os torna altamente resistentes a quebras e danos. Além disso, a sua resistência à flexão de, pelo menos, 70 MPa garante que podem suportar a flexão e a deformação sem fissuras ou fracturas.

Resistência climática

Folha de acrílico fosco são formuladas para serem estáveis aos raios UV, o que significa que elas podem resistir aos efeitos nocivos da radiação ultravioleta do sol. Após 5000 horas de teste de envelhecimento QUV (fonte: QUV accelerated weathering tester), essas placas não mostraram sinais óbvios de amarelecimento ou degradação, tornando-as adequadas para aplicações internas e externas.

Quimicamente estável

Estas folhas são também altamente resistentes a produtos químicos, incluindo álcool, ácidos e bases fracos. Esta estabilidade química torna-as fáceis de limpar e manter, porque é pouco provável que sejam danificadas por produtos de limpeza comuns. Além disso, as suas superfícies não porosas inibem o crescimento de bactérias e outros microrganismos, tornando-as uma escolha higiénica para aplicações nas indústrias alimentar e médica.

Desempenho do tratamento

Facrílico fosco folha é amplamente utilizado na transformação. Utilizando ferramentas e técnicas padrão, como o corte a laser, a termoformação, a serigrafia e a gravação CNC, podem ser facilmente cortados, perfurados, dobrados e moldados. Este facto permite um elevado grau de personalização e flexibilidade de design, permitindo aos fabricantes criar produtos únicos e complexos para satisfazer as necessidades específicas dos clientes.

Principais ocasiões de aplicação

Construção e decoração

Fosco as chapas acrílicas são amplamente utilizadas na arquitetura e na decoração para criar divisórias interiores em escritórios, hotéis e hospitais. O seu aspeto mate proporciona privacidade, ao mesmo tempo que permite a passagem da luz, criando uma atmosfera luminosa e arejada. Também são utilizados como substitutos do vidro fosco na decoração de casas, como portas de casas de banho e chuveiros, onde a segurança e a privacidade são de extrema importância. Além disso, estas placas também são muito populares em espaços comerciais (como lojas de retalho e salas de exposições) para a criação de paredes translúcidas, onde podem ser utilizadas para expor produtos ou criar fundos visualmente impressionantes.

Campo de luz

No sector da iluminação, acrílico fosco folha é utilizado como cobertura de brilho de lâmpadas LED, difusor para caixas de luz publicitárias e cobertura de iluminação paisagística. A sua capacidade de difundir a luz uniformemente e reduzir o encandeamento torna-as ideais para criar efeitos de iluminação suaves e ambientais que melhoram a atração estética geral de um espaço. Além disso, a sua elevada transmissão de luz pode garantir que as lâmpadas emitem a quantidade máxima de luz, melhorando assim a eficiência energética e reduzindo os custos de funcionamento.

Industrial e para fins especiais

Facrílico fosco folha também tem sido aplicado em várias indústrias e domínios especiais. São utilizados como painéis de proteção de ecrãs em produtos electrónicos, que podem proteger ecrãs delicados contra riscos e danos, mantendo simultaneamente uma visibilidade clara. Em instituições médicas, são utilizados como divisórias de salas de operações, proporcionando uma barreira estéril e transparente, para que o pessoal médico possa monitorizar os pacientes sem prejudicar a privacidade. Além disso, devido à sua versatilidade e atração estética, estes painéis são muito populares entre artistas e designers para criar obras de arte e instalações únicas e inovadoras.

Perguntas frequentes (FAQ)

P: Qual é a diferença entre chapa acrílica fosca e uma folha de acrílico normal?

R: A principal diferença reside na suavidade da superfície e nas caraterísticas de difusão da luz. Acrílico fosco folha tem uma superfície mate, que pode reduzir o brilho e proporciona uma difusão uniforme da luz, ao passo que a placa acrílica convencional tem uma superfície brilhante, que pode produzir reflexos e sombras ásperas.

P: A folha de acrílico mate pode ser reciclada?

R: Sim, chapa acrílica fosca são recicláveis. Podem ser fundidos e transformados em novos produtos, reduzindo assim os resíduos e contribuindo para um processo de fabrico mais sustentável.

P: A placa acrílica mate é adequada para utilização no exterior?

R: Sim, fosco folha de acrílico são adequados para utilização no exterior devido à sua estabilidade aos raios UV e resistência às intempéries. No entanto, é necessária uma instalação correta e proteção contra condições meteorológicas extremas para garantir a sua vida útil e desempenho.

Em conclusão, fosco folha de acrílico oferecem uma combinação única de atração estética e desempenho funcional que os torna a escolha ideal para uma vasta gama de aplicações, incluindo painéis LED, caixas de luz e divisórias interiores. Ao compreender as suas principais caraterísticas, cenários de aplicação e critérios de seleção, pode tomar uma decisão sensata e escolher o melhor acrílico fosco folha de acordo com as suas necessidades específicas.

Categorias de artigos

- Blogues23

Categorias de produtos

- Acrílico 19

- Folha de acrílico 17

- Folha de acrílico transparente 1

- Folha de acrílico colorida 1

- Sanitário(Banheira Folha de acrílico 1

- Folha de espelho acrílico 1

- Folha de acrílico para aquário 1

- Folha de acrílico para dia e noite 1

- Folha de acrílico resistente ao fogo 1

- Folha de acrílico fosco/fosco 1

- Folha de acrílico com brilho/tecido 1

- Acrílico resistente a impactos 1

- Filtro de infravermelhos Acrílico 1

- Folha de acrílico LGP 1

- Chapa acrílica anti-ruído 0

- Folha de acrílico para janelas de veículos de recreio 1

- Folha de acrílico para sinalização 1

- Vedação com barreira acústica 1

- Folha de acrílico espesso especial 1

- Acrílico transmissor de UV 1

- Tubo e haste de acrílico 2

- Folha de acrílico 17

- PVC 2

Publicações recentes

O que é placa de espuma de PVC colorida ...

03/05/2026 Comentários fechados em What Is PVC Color Foam Board and Why Is It Widely Used in Advertising, Construction & Industrial Projects?Guia definitivo para a placa de espuma de PVC: ...

02/27/2026 Comentários fechados em Ultimate Guide to PVC Foam Board: Properties, Uses, and BenefitsO que procurar ao comprar ...

02/12/2026 Comentários fechados em What to Look for When Buying a High-Quality Acrylic Tube Product for Professional Use?O que é uma barra de acrílico e ...

02/05/2026 Comentários fechados em What is an acrylic rod and how do you use it? Acrylic Rod Sizes, Applications & Buying GuideGuia para principiantes: O que deve saber ...

01/29/2026 Comentários fechados em Beginner’s Guide: What You Must Know Before Buying a RV window acrylic sheetPedir um orçamento rápido

Evite o intermediário. Desbloqueie os preços diretos da fábrica.