+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

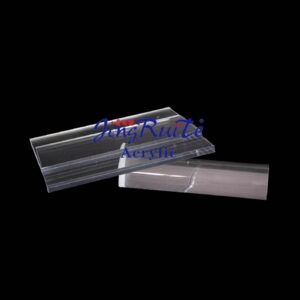

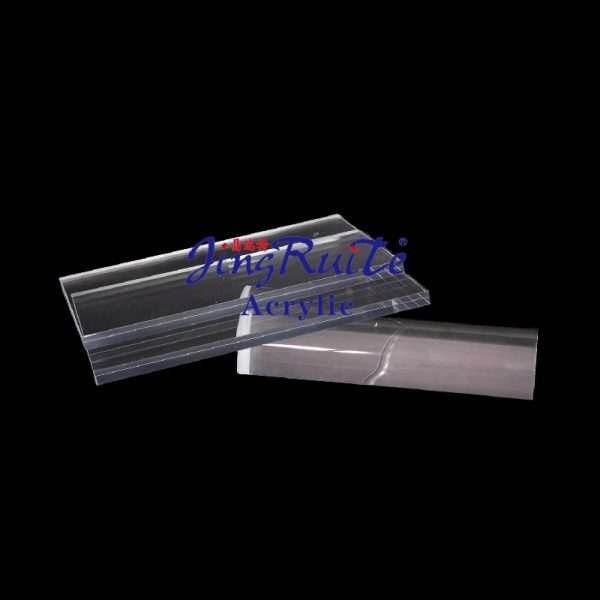

Clear Acrylic Riser Set – Multi-Level Plexiglass Shelves for Retail

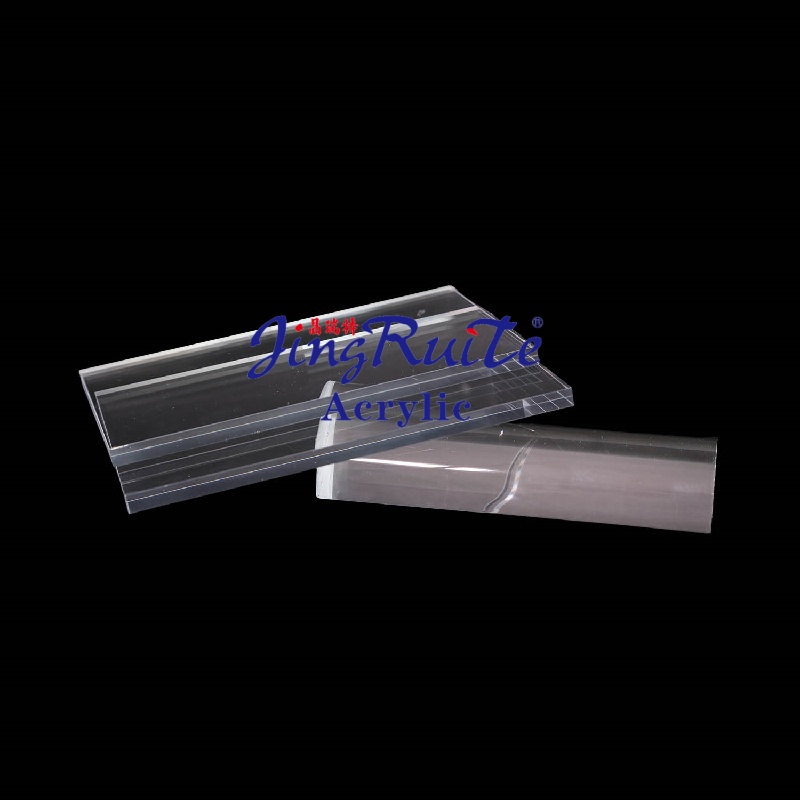

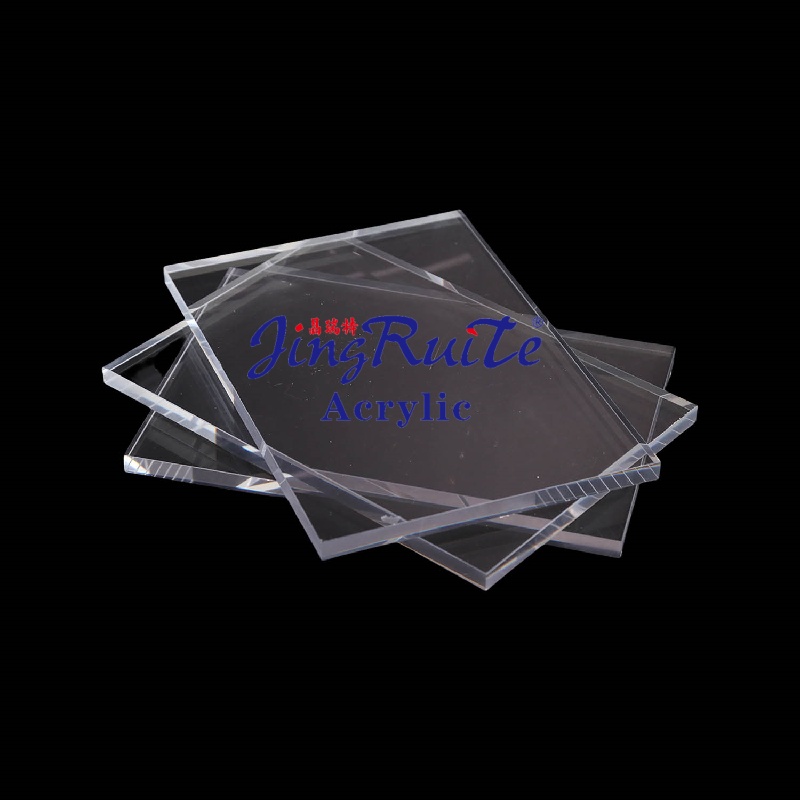

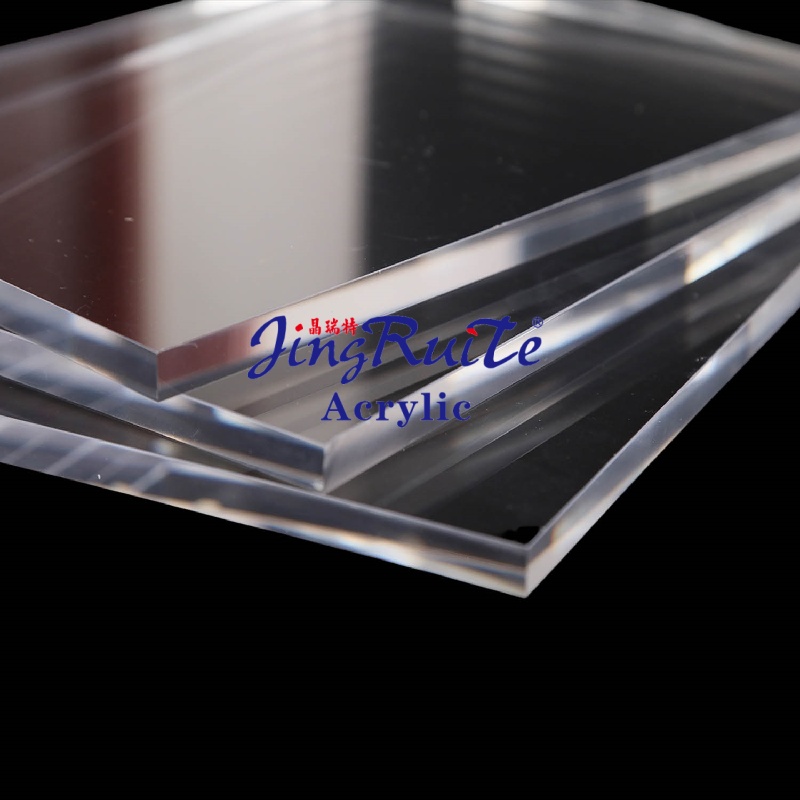

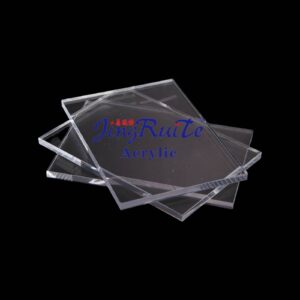

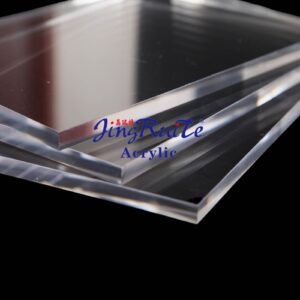

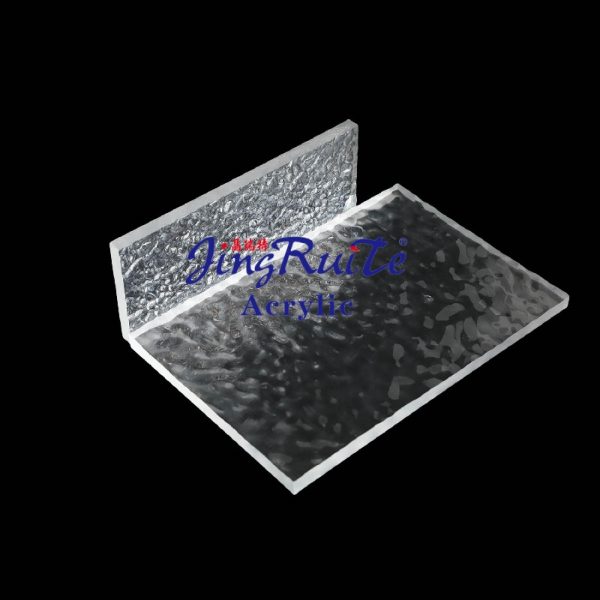

Clear Acrylic Sheet is a highly transparent sheet made from 100% optical-grade PMMA (Polymethyl Methacrylate) through casting or extrusion processes. It offers 92% light transmittance, comparable to optical glass, yet provides 17 times the impact strength and 50% weight advantage of glass. The surface undergoes precision polishing with Ra value ≤0.02μm, achieving a mirror-like finish. Standard size is 1220×2440mm with thickness ranging from 1mm-50mm, supporting custom cutting, making it an ideal glass replacement material.

Clear Acrylic Sheet is a highly transparent sheet made from 100% optical-grade PMMA (Polymethyl Methacrylate) through casting or extrusion processes. It offers 92% light transmittance, comparable to optical glass, yet provides 17 times the impact strength and 50% weight advantage of glass. The surface undergoes precision polishing with Ra value ≤0.02μm, achieving a mirror-like finish. Standard size is 1220×2440mm with thickness ranging from 1mm-50mm, supporting custom cutting, making it an ideal glass replacement material.

Key Features

- Superior Optical Performance: 92% visible light transmittance, haze <1%, no optical distortion

- Mechanical Strength: Impact strength 16kJ/m², tensile strength 65MPa, flexural strength 90MPa

- Weather Resistance: Temperature stability from -40℃ to 80℃, UV stabilizer ensures no yellowing for 5 years outdoors

- Processing Flexibility: Thermoformable (140-160℃), laser cutting, CNC engraving, excellent bonding performance

- Surface Characteristics: Hardness HB, easy to clean, fingerprint-resistant, scratch-resistant (pencil hardness 2H)

- Environmental Safety: Complies with FDA food contact standards, RoHS certified, no formaldehyde emission

Application Scenarios

Architecture and Decoration

- Daylighting Engineering: skylights, greenhouse panels, secondary glazing

- Interior Design: shower screens, furniture panels, room dividers

- Building Curtain Walls: transparent facade elements, canopies, balustrades

Advertising and Display

- Signage: illuminated signs, display cases, point-of-purchase displays

- Retail: product display, cosmetic counters, jewelry showcases

- Exhibition: trade show booths, light boxes, promotional displays

Industrial and Special Applications

- Medical Equipment: surgical instrument trays, medical device housings

- Electronics: display screens, touch panels, protective covers

- Optical Applications: lenses, light guides, precision instruments

Technical Parameters

| Property | Test Method | Value |

| Light Transmission | ASTM D1003 | ≥92% |

| Density | ASTM D792 | 1.19 g/cm³ |

| Impact Strength (Notched Izod) | ASTM D256 | 16 kJ/m² |

| Tensile Strength | ASTM D638 | 65 MPa |

| Flexural Strength | ASTM D790 | 90 MPa |

| Heat Deflection Temperature | ASTM D648 | 85°C @ 264 psi |

| Water Absorption | ASTM D570 | ≤0.3% |

| Linear Thermal Expansion | ASTM D696 | 7×10⁻⁵ /°C |

Processing and Installation

- Cutting: Laser cutting (recommended for precision), circular saw with fine-tooth blade

- Thermoforming: Heat to 140-160°C, minimum bend radius 3× material thickness

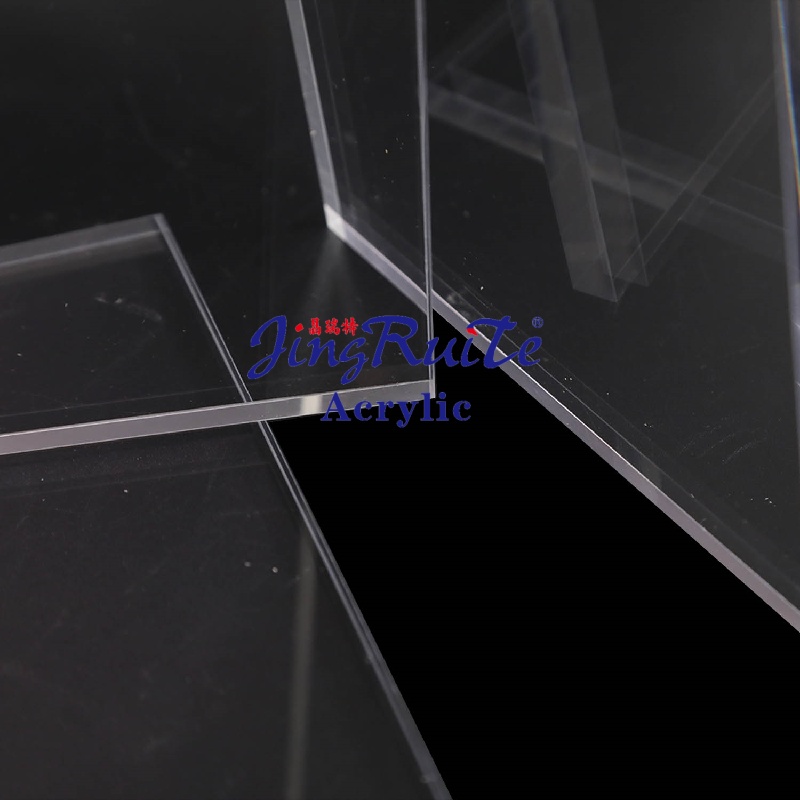

- Bonding: Solvent cement (dichloromethane-based), UV-curing adhesives

- Edge Finishing: Flame polishing, diamond polishing, sandblasting

- Mounting: Mechanical fasteners with washers, adhesive mounting, edge clamping

Specifications and Packaging

- Standard Sizes: 1220×2440mm, 1524×3048mm

- Thickness Range: 1mm, 2mm, 3mm, 5mm, 8mm, 10mm, up to 50mm

- Surface Options: Clear, frosted, non-glare, UV-resistant coating

- Packaging: PE protective film on both sides, wooden pallet for transportation

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2