+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

Turquoise Opaque Acrylic Board 3 mm – Solid Aqua Plexiglass

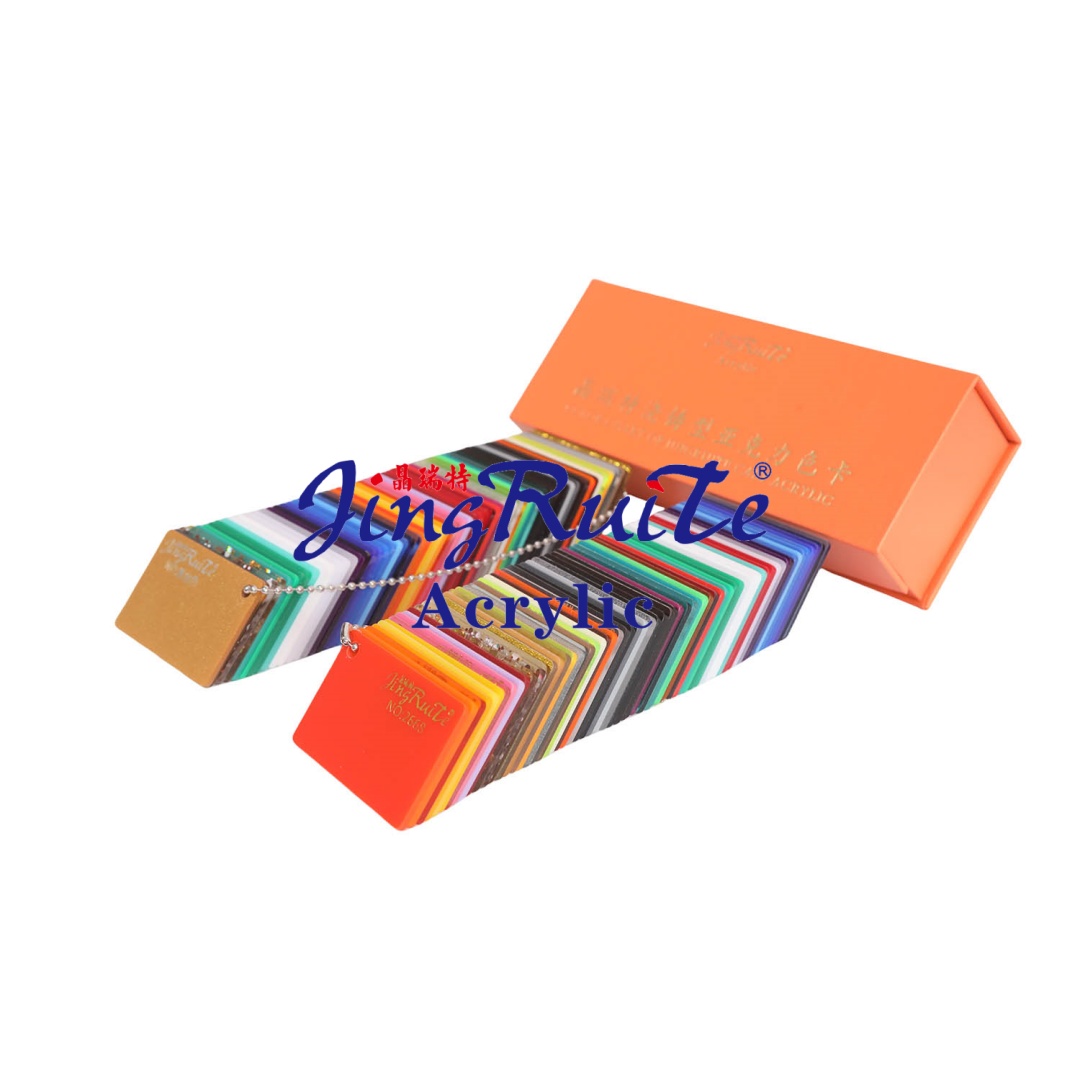

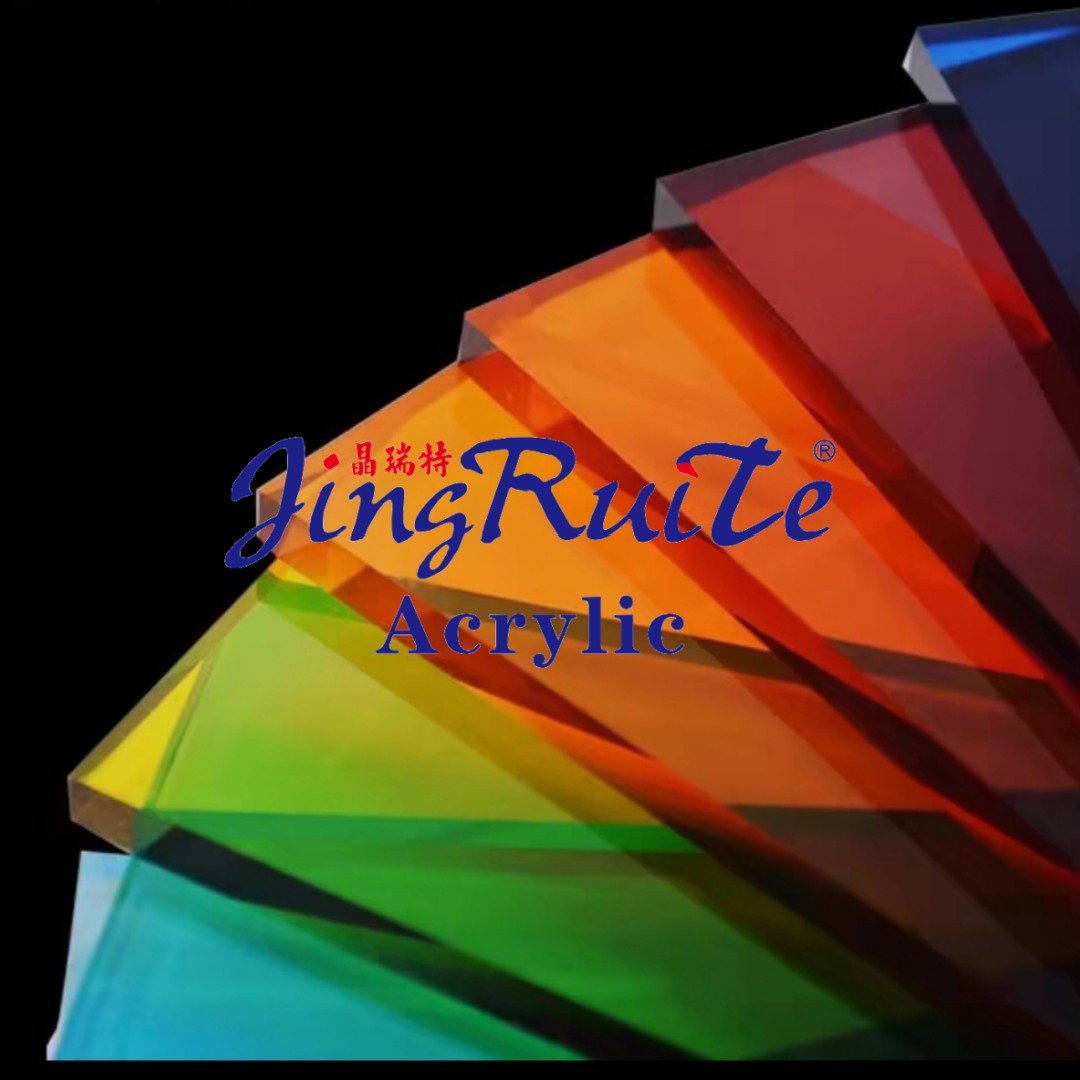

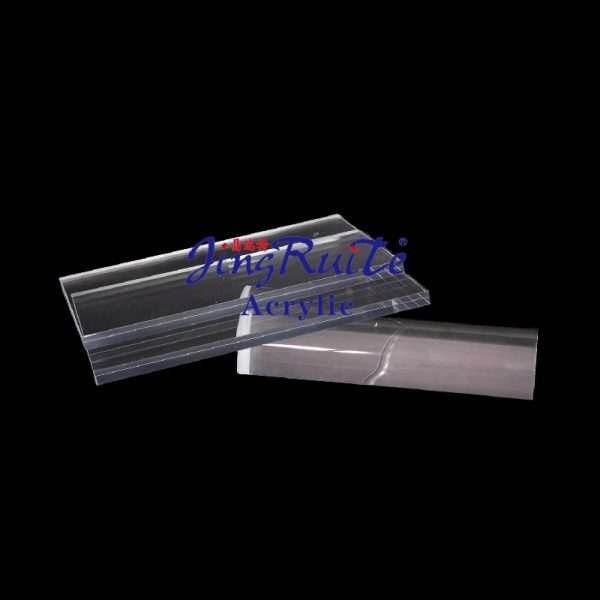

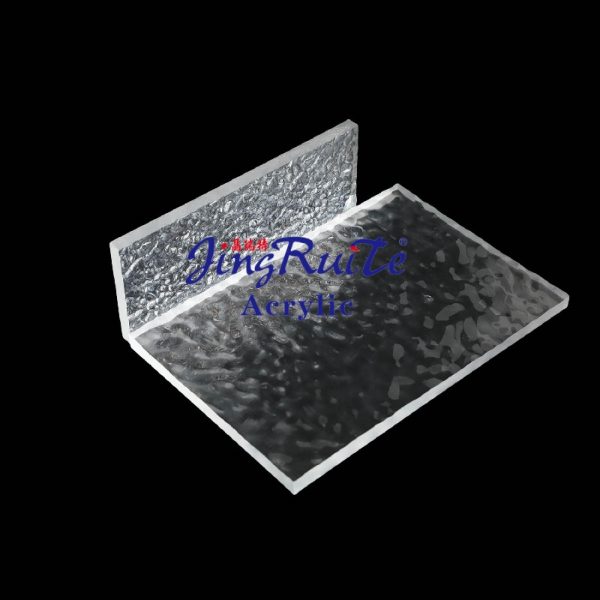

Color Acrylic Sheet is a colored sheet made by adding inorganic pigments or dyes to PMMA substrate, produced through casting or extrusion processes. It offers three major series: transparent, translucent and opaque, including over 50 standard colors and custom colors (Pantone color matching). Sheet thickness ranges from 1mm to 50mm, with surface options of high gloss, matte or textured finishes, and double-sided PE protective film. With 92% light transmittance (transparent colors), excellent weather resistance and processability, it is an ideal material for decoration, signage and lighting applications.

Color Acrylic Sheet is a colored sheet made by adding inorganic pigments or dyes to PMMA substrate, produced through casting or extrusion processes. It offers three major series: transparent, translucent and opaque, including over 50 standard colors and custom colors (Pantone color matching). Sheet thickness ranges from 1mm to 50mm, with surface options of high gloss, matte or textured finishes, and double-sided PE protective film. With 92% light transmittance (transparent colors), excellent weather resistance and processability, it is an ideal material for decoration, signage and lighting applications.

Key Features

- Color Performance: ΔE≤2 color difference, strict batch-to-batch color control, outdoor 5-year fading rate ≤5%

- Optical Quality: Transparent color series with 85%-92% light transmittance, adjustable haze 5%-95%, refractive index 1.49

- Physical Strength: Impact strength 16kJ/m², flexural strength ≥90MPa, Shore hardness M90-95

- Weather Stability: UV absorber content 0.2%-0.5%, yellowing index ΔE<3 (QUV 5000 hours)

- Processing Performance: Thermoformable (140-160℃), laser engraving, CNC milling, printing adhesion ≥3N/cm

- Environmental Certification: Complies with RoHS, REACH standards, heavy metal content <10ppm, zero formaldehyde emission

Application Scenarios

Decoration and Architecture

- Interior Design: Colored partitions, wall decorative panels, furniture panels

- Building Curtain Walls: Colored daylighting panels, special-shaped decorative components, landmark building skins

- Home Decoration: Custom furniture, artistic screens, kitchen and bathroom ceilings

Advertising and Signage

- Signage Production: Three-dimensional letters, backlit signs, wayfinding systems

- Exhibition Display: Booth decoration, product display racks, POP advertising

- Digital Printing: UV inkjet substrates, acrylic light boxes

Special Applications

- Lighting Engineering: Colored lamp shades, LED decorative lights, landscape lighting

- Artistic Creation: Sculptural artworks, installation art, stage props

- Electronic Panels: Equipment front panels, control panels, display windows

Technical Parameters

| Performance Item | Test Standard | Typical Value |

| Density | ASTM D792 | 1.19 g/cm³ |

| Light Transmittance (Transparent Colors) | ASTM D1003 | 85-92 % |

| Heat Distortion Temperature | ASTM D648 | 85-90 ℃ |

| Impact Strength (Unnotched) | ASTM D256 | 16 kJ/m² |

| Linear Thermal Expansion Coefficient | ASTM D696 | 7×10⁻⁵ /℃ |

| Vicat Softening Point | ASTM D1525 | 100-105 ℃ |

| Weathering Resistance | ISO 4892-2 | Class 5 (5 years outdoor) |

| Flammability Rating | UL94 | HB |

Colors and Specifications

| Color Series | Representative Color Codes | Thickness Range | Surface Treatment |

| Transparent Colors | Red(2423), Blue(2050), Green(3030) | 1-20mm | High Gloss/Matte |

| Translucent Colors | Milky White(2447), Frosted Blue(2114), Brown(2404) | 2-30mm | Frosted/Fine Texture |

| Opaque Colors | Black(2025), Yellow(2037), Orange(2119) | 3-50mm | High Gloss/Textured |

| Special Effects | Fluorescent, Pearlescent, Gradient | 3-20mm | Custom Texture |

Processing Guidelines

- Cutting Tools: Laser cutting (recommended power 50-100W), circular saw (100-120 tooth alloy blade)

- Thermoforming Process: Uniform heating to 150℃, bending radius ≥3×thickness, cooling time ≥5 minutes

- Surface Treatment: Paintable (acrylic paint), silk-screen printable (UV inks), coatable (metallization)

- Bonding Methods: Acrylic special glue (e.g., dichloromethane), UV glue (recommended for transparent colors)

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2