+86 180 1040 9086

- Inicio

- Productos

- Acrílico

- Lámina acrílica

- Lámina acrílica transparente

- Lámina acrílica de color

- Lámina acrílica sanitaria (bañera)

- Espejo acrílico

- Espejo acrílico

- Lámina acrílica para acuarios

- Lámina acrílica Day&Night

- Plancha acrílica ignífuga

- Placa acrílica mate/esmerilada

- Hoja acrílica de purpurina/tejido

- Acrílico resistente a los impactos

- Filtro infrarrojo acrílico

- Lámina acrílica LGP

- Lámina acrílica antirruido

- Lámina acrílica para ventanas de vehículos recreativos

- Chapa acrílica de señalización

- Valla insonorizante

- Lámina acrílica especial gruesa

- Acrílico transmisor de UV

- Tubo y varilla acrílicos

- Productos acrílicos

- Lámina acrílica

- PVC

- Acrílico

- Quiénes somos

- Solución

- Blogs

- Contáctenos

DETALLES DEL PRODUCTO

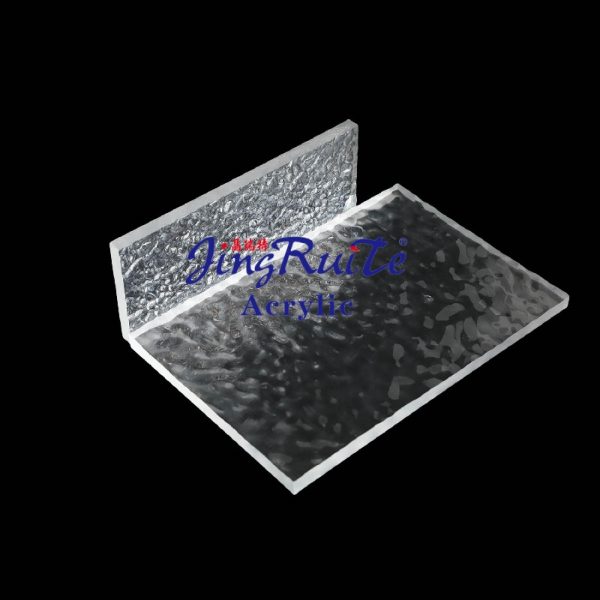

Placa acrílica opaca turquesa 3 mm - Plexiglás Aqua sólido

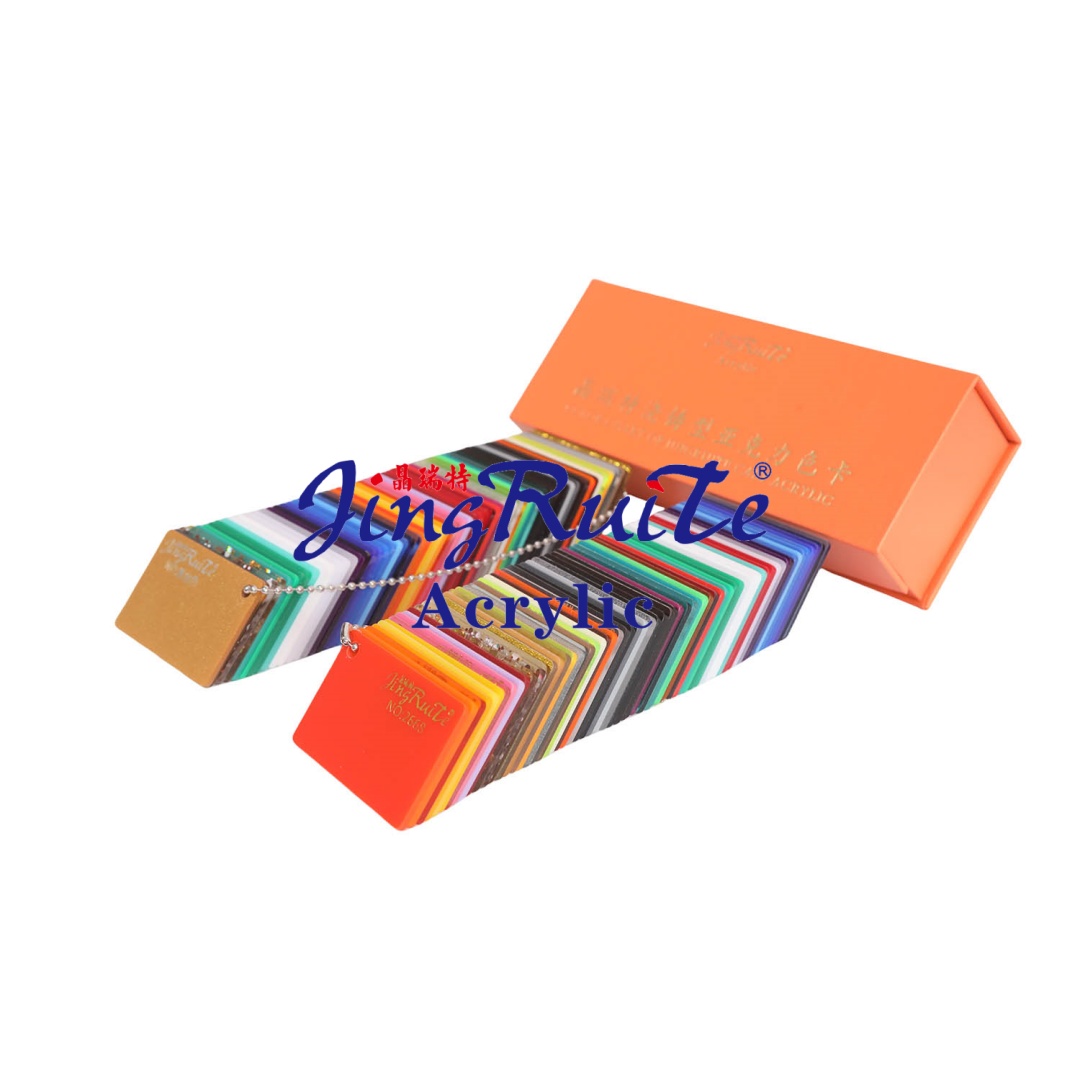

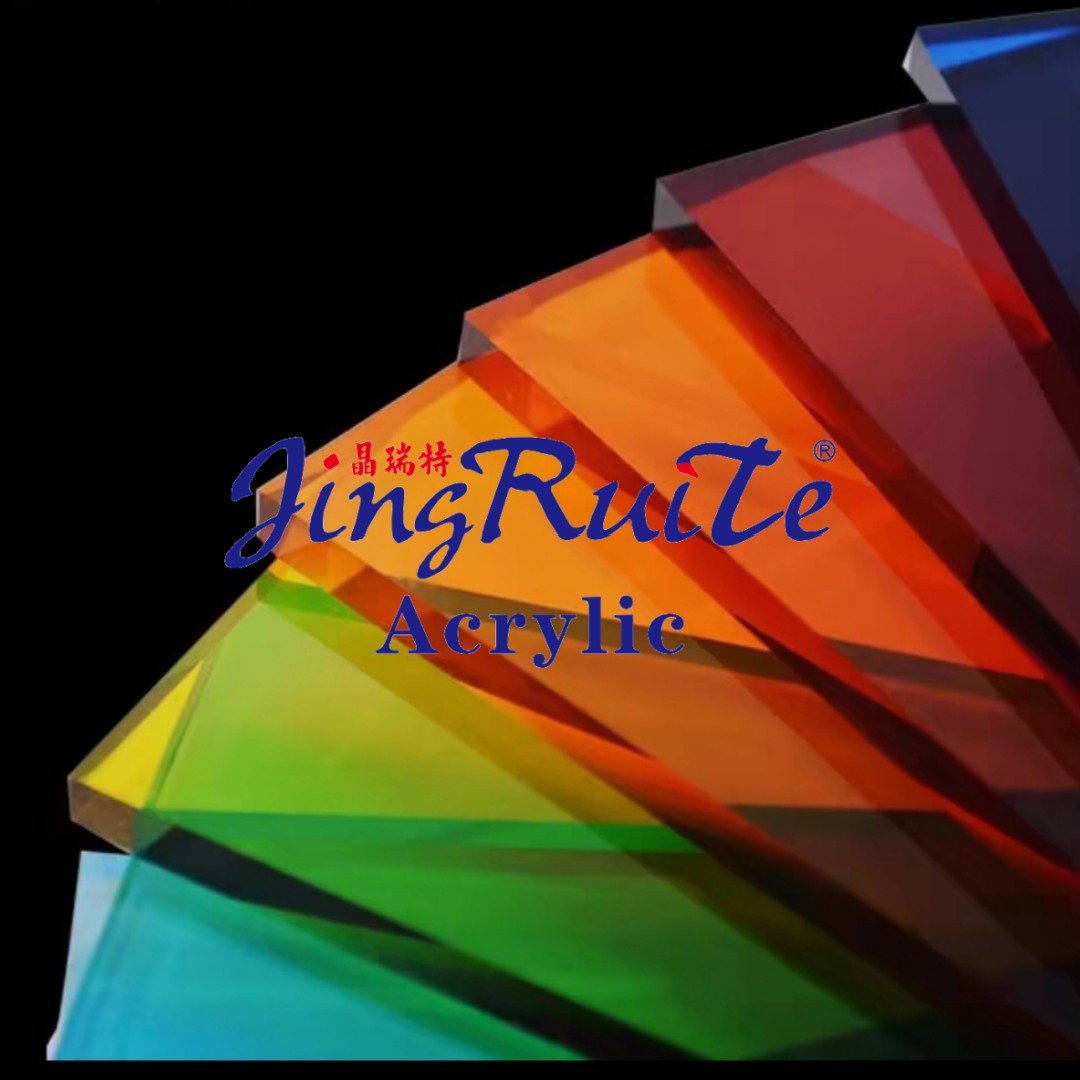

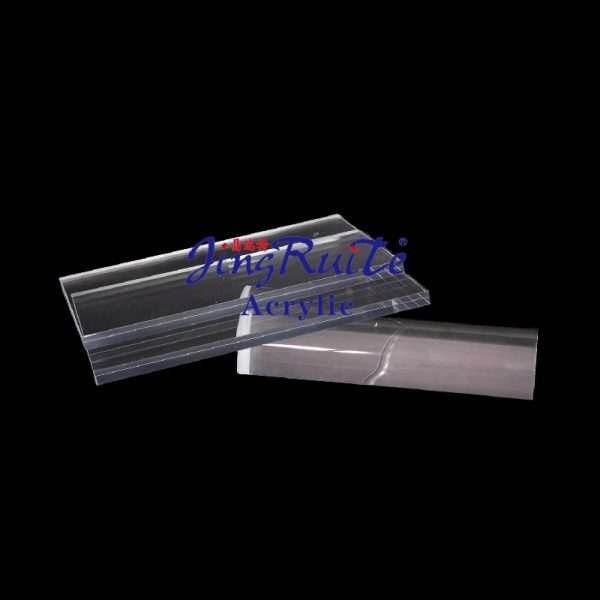

Color Lámina acrílica Es una lámina coloreada fabricada añadiendo pigmentos inorgánicos o tintes al sustrato de PMMA, producida mediante procesos de moldeo o extrusión. Ofrece tres series principales: transparente, translúcida y opaca, que incluyen más de 50 colores estándar y colores personalizados (correspondencia de colores Pantone). El grosor de la lámina varía entre 1 mm y 50 mm, con opciones de acabado de alta brillantez, mate o texturizado, y película protectora de PE por ambas caras. Con una transmitancia de luz de 92% (colores transparentes), una excelente resistencia a la intemperie y facilidad de procesamiento, es un material ideal para aplicaciones de decoración, señalización e iluminación.

Color Lámina acrílica Es una lámina coloreada fabricada añadiendo pigmentos inorgánicos o tintes al sustrato de PMMA, producida mediante procesos de moldeo o extrusión. Ofrece tres series principales: transparente, translúcida y opaca, que incluyen más de 50 colores estándar y colores personalizados (correspondencia de colores Pantone). El grosor de la lámina varía entre 1 mm y 50 mm, con opciones de acabado de alta brillantez, mate o texturizado, y película protectora de PE por ambas caras. Con una transmitancia de luz de 92% (colores transparentes), una excelente resistencia a la intemperie y facilidad de procesamiento, es un material ideal para aplicaciones de decoración, señalización e iluminación.

Características principales

- Rendimiento del color: ΔE≤2 diferencia de color, estricto control de color lote a lote, tasa de decoloración en exteriores de 5 años ≤5%

- Calidad óptica: Serie de color transparente con transmisión de luz 85%-92%, neblina ajustable 5%-95%, índice de refracción 1,49

- Fuerza física: Resistencia al impacto 16kJ/m², resistencia a la flexión ≥90MPa, dureza Shore M90-95.

- Estabilidad meteorológica: Contenido de absorbente UV 0,2%-0,5%, índice de amarilleamiento ΔE<3 (QUV 5000 horas)

- Rendimiento del procesamiento: Termoformable (140-160℃), grabado láser, fresado CNC, impresión adherencia ≥3N/cm.

- Certificación medioambiental: Cumple las normas RoHS, REACH, contenido en metales pesados <10ppm, cero emisiones de formaldehído.

Escenarios de aplicación

Decoración y arquitectura

- Diseño interior: Tabiques de colores, paneles decorativos para paredes, paneles para muebles

- Construcción de muros cortina: Paneles de iluminación natural de colores, componentes decorativos de formas especiales, pieles de edificios emblemáticos

- Decoración del hogar: Muebles a medida, mamparas artísticas, techos de cocina y baño

Publicidad y señalización

- Producción de rótulos: Letras tridimensionales, rótulos retroiluminados, sistemas de orientación

- Exposición: Decoración de stands, expositores de productos, publicidad POP

- Impresión digital: Soportes de inyección de tinta UV, cajas de luz acrílicas

Aplicaciones especiales

- Luminotecnia: Pantallas de lámparas de colores, luces decorativas LED, iluminación paisajística

- Creación artística: Obras escultóricas, instalaciones artísticas, atrezo escénico

- Paneles electrónicos: Paneles frontales de los equipos, paneles de control, ventanas de visualización

Parámetros técnicos

| Artículo de rendimiento | Norma de ensayo | Valor típico |

| Densidad | ASTM D792 | 1,19 g/cm³ |

| Transmitancia de la luz (colores transparentes) | ASTM D1003 | 85-92 % |

| Temperatura de distorsión térmica | ASTM D648 | 85-90 ℃ |

| Resistencia al impacto (sin entallar) | ASTM D256 | 16 kJ/m² |

| Coeficiente de dilatación térmica lineal | ASTM D696 | 7×10-⁵ /℃ |

| Punto de reblandecimiento Vicat | ASTM D1525 | 100-105 ℃ |

| Resistencia a la intemperie | ISO 4892-2 | Clase 5 (5 años al aire libre) |

| Grado de inflamabilidad | UL94 | HB |

Colores y especificaciones

| Serie Color | Códigos de colores representativos | Gama de espesores | Tratamiento de superficies |

| Colores transparentes | Rojo(2423), Azul(2050), Verde(3030) | 1-20 mm | Alto brillo/mate |

| Colores translúcidos | Blanco lechoso(2447), Azul esmerilado(2114), Marrón(2404) | 2-30 mm | Esmerilado/Textura fina |

| Colores opacos | Negro(2025), Amarillo(2037), Naranja(2119) | 3-50 mm | Alto brillo/texturizado |

| Efectos especiales | Fluorescente, Nacarado, Degradado | 3-20 mm | Textura personalizada |

Directrices de tratamiento

- Herramientas de corte: Corte por láser (potencia recomendada 50-100W), sierra circular (hoja de aleación de 100-120 dientes)

- Proceso de termoformado: Calentamiento uniforme a 150℃, radio de curvatura ≥3×espesor, tiempo de enfriamiento ≥5 minutos.

- Tratamiento de superficies: Pintable (pintura acrílica), serigrafiable (tintas UV), recubrible (metalización)

- Métodos de adhesión: Pegamento acrílico especial (por ejemplo, diclorometano), pegamento UV (recomendado para colores transparentes)

Productos relacionados

Categorías de productos

- Acrílico 19

- Lámina acrílica 17

- Lámina acrílica transparente 1

- Lámina acrílica de color 1

- Sanitario(Bañera Lámina acrílica 1

- Espejo acrílico 1

- Lámina acrílica para acuarios 1

- Lámina acrílica Day&Night 1

- Plancha acrílica ignífuga 1

- Placa acrílica mate/esmerilada 1

- Hoja acrílica de purpurina/tejido 1

- Acrílico resistente a los impactos 1

- Filtro infrarrojo acrílico 1

- Lámina acrílica LGP 1

- Lámina acrílica antirruido 0

- Lámina acrílica para ventanas de vehículos recreativos 1

- Chapa acrílica de señalización 1

- Valla insonorizante 1

- Lámina acrílica especial gruesa 1

- Acrílico transmisor de UV 1

- Tubo y varilla acrílicos 2

- Lámina acrílica 17

- PVC 2

Solicitar un presupuesto rápido

Olvídese de los intermediarios. Obtenga precios directos de fábrica.

Categorías de productos

- Acrílico 19

- Lámina acrílica 17

- Lámina acrílica transparente 1

- Lámina acrílica de color 1

- Sanitario(Bañera Lámina acrílica 1

- Espejo acrílico 1

- Lámina acrílica para acuarios 1

- Lámina acrílica Day&Night 1

- Plancha acrílica ignífuga 1

- Placa acrílica mate/esmerilada 1

- Hoja acrílica de purpurina/tejido 1

- Acrílico resistente a los impactos 1

- Filtro infrarrojo acrílico 1

- Lámina acrílica LGP 1

- Lámina acrílica antirruido 0

- Lámina acrílica para ventanas de vehículos recreativos 1

- Chapa acrílica de señalización 1

- Valla insonorizante 1

- Lámina acrílica especial gruesa 1

- Acrílico transmisor de UV 1

- Tubo y varilla acrílicos 2

- Lámina acrílica 17

- PVC 2