+86 180 1040 9086

商品詳細

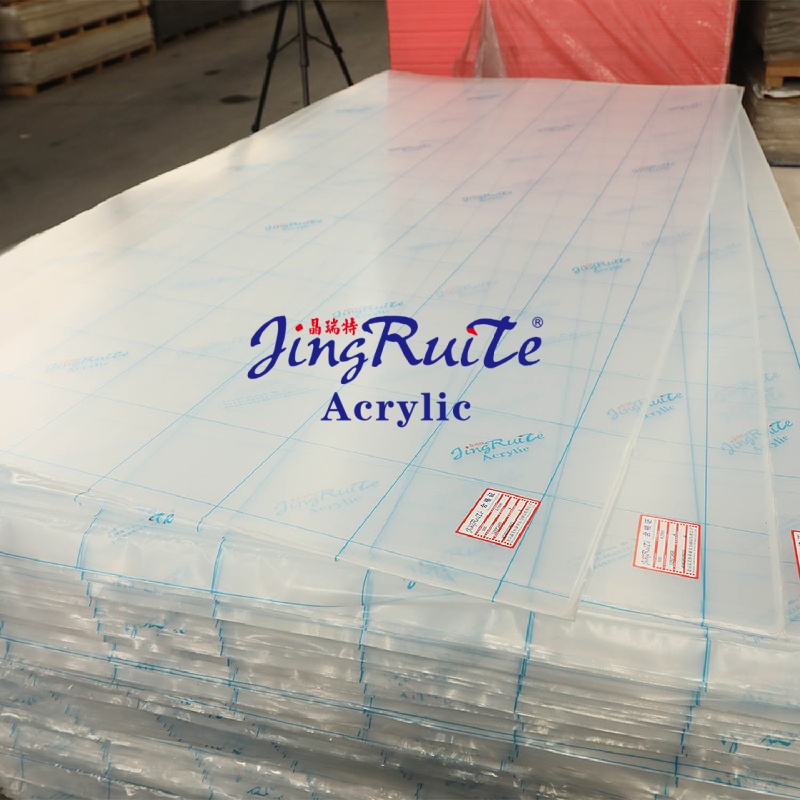

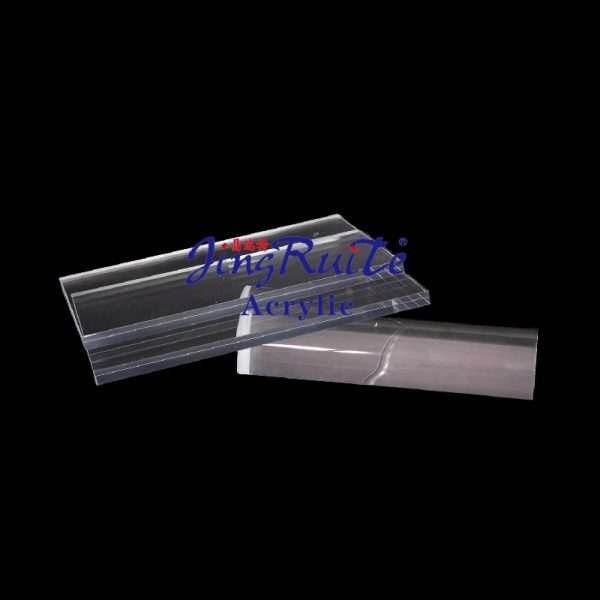

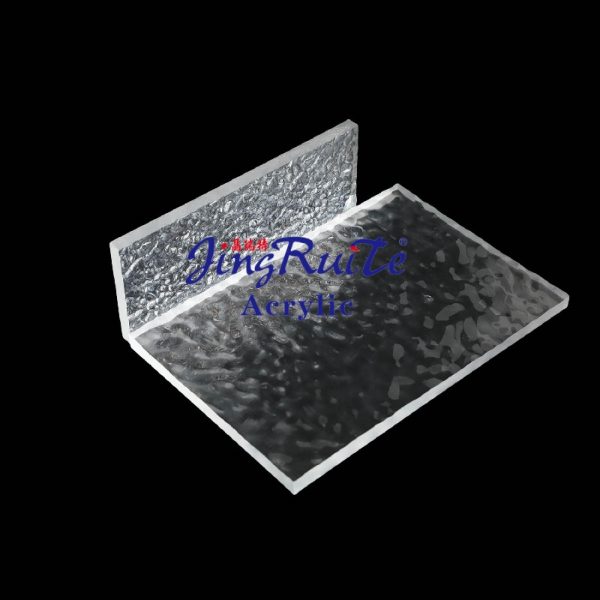

難燃アクリルシート

難燃アクリル樹脂シートは、100%の三菱MMA純原料を使用して製造されたUL94 V-0規格認定の高性能難燃材料です。アクリルの高い光線透過率(93.7%以上)と優れた難燃性を兼ね備えています。独自の銀イオン抗菌技術により、大腸菌や黄色ブドウ球菌を抑制するだけでなく(抗菌率99%以上)、ISO22196国際規格認証にも適合しており、防火安全や衛生基準が厳しい公共建築物や医療環境にも適しています。.

製品分類:日本 火はアクリルシートを評価した

難燃アクリル樹脂シートは、100%の三菱MMA純原料を使用して製造されたUL94 V-0規格認定の高性能難燃材料です。アクリルの高い光線透過率(93.7%以上)と優れた難燃性を兼ね備えています。独自の銀イオン抗菌技術により、大腸菌や黄色ブドウ球菌を抑制するだけでなく(抗菌率99%以上)、ISO22196国際規格認証にも適合しており、防火安全や衛生基準が厳しい公共建築物や医療環境にも適しています。.

コア機能

- 難燃性能:UL94 V-0認定(垂直燃焼試験で10秒以内に自己消火、点火剤滴下なし)、限界酸素指数(LOI)>30%、GB/T 2408-2008規格準拠 - 機械的強度:機械的強度:引張強さ74.7MPa、曲げ強さ64MPa、ノッチ付き衝撃強さ953J/m、普通ガラスの17倍の耐衝撃性 - 熱安定性:熱変形温度78℃(1.8MPa荷重下)、連続使用温度範囲-40℃~80℃ - 光学性能:光線透過率 93.7%、ヘイズ <1%、表面硬度 Rockwell R 94 - 環境認証:環境認証:EPA(米国環境保護庁)およびECHAに登録、ハロゲンフリー難燃剤含有

アプリケーション・シナリオ

- 公共施設地下鉄ホームのスクリーンドア、空港ターミナルの仕切り、病院の廊下のガードレール

- 電子機器:サーバーキャビネットパネル、ディスプレイハウジング、充電パイル保護スクリーン

- 輸送高速鉄道の窓、船の内装、救急車の客室仕切り

- 産業用設備クリーンルーム観察窓、実験室用ヒュームフード、防爆ランプカバー

技術パラメーター

| パラメータ | 試験基準 | 価値 |

| 密度 | ASTM D792 | 1.35 g/cm³ |

| 光線透過率 | ASTM D1003 | ≥93.7% |

| 難燃性 | UL 94 | V-0/5V |

| 熱変形温度 | ASTM D648 | 78℃ |

| 吸水率(24時間) | ISO 62 | 0.3% |

| 表面抵抗 | GB/T 1410 | 10⁶~10⁸ Ω |

加工と設置

- 成形加工:熱成形(163-200℃)、CNC彫刻、レーザー切断、最小曲げ半径≥10×シート厚に対応 - 接続方法:アクリル専用UV接着剤またはクロロホルム溶剤溶接の使用を推奨、継ぎ目に0.5mmの伸縮継手が必要 - 取り付け仕様:電気化学的腐食を防ぐため、金属ブラケットとの直接接触は避ける。

注意事項

- 洗浄の際は、アルコールや研磨剤入りのクリーナーを使用せず、中性石鹸水を使用することを推奨します。長期間屋外で使用する場合は、耐用年数を15年以上に延ばすためにUVプロテクション・コーティングを施す必要があります。

製品カテゴリー

- アクリル 19

- アクリル板 17

- 透明アクリル板 1

- カラーアクリル板 1

- サニタリー(バスタブ アクリル板 1

- アクリルミラーシート 1

- 水族館アクリルシート 1

- Day&Nightアクリルシート 1

- 火はアクリルシートを評価した 1

- 曇らされる/マットのアクリルシート 1

- グリッター/ファブリックアクリルシート 1

- 耐衝撃性アクリル 1

- 赤外線フィルター アクリル 1

- 導光板アクリルシート 1

- 遮音アクリル板 0

- RVウィンドウアクリルシート 1

- アクリルシート 1

- 遮音フェンス 1

- 特殊厚手アクリル板 1

- 紫外線透過アクリル 1

- アクリル管&ロッド 2

- アクリル板 17

- PVC 2

製品カテゴリー

- アクリル 19

- アクリル板 17

- 透明アクリル板 1

- カラーアクリル板 1

- サニタリー(バスタブ アクリル板 1

- アクリルミラーシート 1

- 水族館アクリルシート 1

- Day&Nightアクリルシート 1

- 火はアクリルシートを評価した 1

- 曇らされる/マットのアクリルシート 1

- グリッター/ファブリックアクリルシート 1

- 耐衝撃性アクリル 1

- 赤外線フィルター アクリル 1

- 導光板アクリルシート 1

- 遮音アクリル板 0

- RVウィンドウアクリルシート 1

- アクリルシート 1

- 遮音フェンス 1

- 特殊厚手アクリル板 1

- 紫外線透過アクリル 1

- アクリル管&ロッド 2

- アクリル板 17

- PVC 2