+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

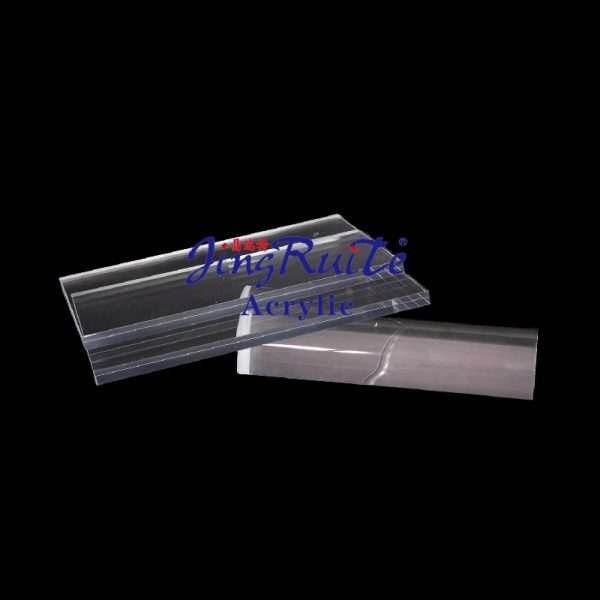

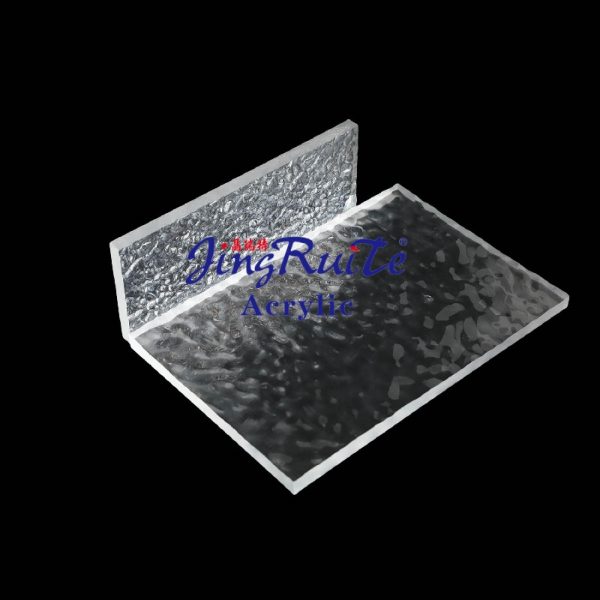

Flame Retardant Acrylic Sheet

Flame Retardant Acrylic Sheet is a high-performance fire-resistant material certified to UL94 V-0 standard, manufactured using 100% pure Mitsubishi MMA raw material. It combines high light transmittance (≥93.7%) of acrylic with excellent flame retardant properties. Its unique silver ion antibacterial technology not only inhibits Escherichia coli and Staphylococcus aureus (antibacterial rate >99%) but also meets ISO 22196 international standard certification, making it suitable for public buildings and medical environments with strict requirements for fire safety and hygiene standards.

Flame Retardant Acrylic Sheet is a high-performance fire-resistant material certified to UL94 V-0 standard, manufactured using 100% pure Mitsubishi MMA raw material. It combines high light transmittance (≥93.7%) of acrylic with excellent flame retardant properties. Its unique silver ion antibacterial technology not only inhibits Escherichia coli and Staphylococcus aureus (antibacterial rate >99%) but also meets ISO 22196 international standard certification, making it suitable for public buildings and medical environments with strict requirements for fire safety and hygiene standards.

Core Features

- Flame Retardant Performance: UL94 V-0 certified (self-extinguishing within 10 seconds in vertical burning test, no dripping igniters), Limiting Oxygen Index (LOI) >30%, compliant with GB/T 2408-2008 standard • Mechanical Strength: Tensile strength 74.7 MPa, flexural strength 64 MPa, notched impact strength 953 J/m, impact resistance 17 times that of ordinary glass • Thermal Stability: Heat distortion temperature 78℃ (under 1.8 MPa load), continuous operating temperature range -40℃~80℃ • Optical Performance: Light transmittance 93.7%, haze <1%, surface hardness up to Rockwell R 94 • Environmental Certification: Registered with EPA (U.S. Environmental Protection Agency) and ECHA, halogen-free flame retardants

Application Scenarios

- Public Buildings: Subway platform screen doors, airport terminal partitions, hospital corridor guardrails

- Electronic Equipment: Server cabinet panels, display housings, charging pile protective screens

- Transportation: High-speed rail windows, ship interiors, ambulance medical cabin partitions

- Industrial Facilities: Clean room observation windows, laboratory fume hoods, explosion-proof lamp covers

Technical Parameters

| Parameter | Test Standard | Value |

| Density | ASTM D792 | 1.35 g/cm³ |

| Light Transmittance | ASTM D1003 | ≥93.7% |

| Flame Retardant Rating | UL 94 | V-0/5V |

| Heat Distortion Temperature | ASTM D648 | 78℃ |

| Water Absorption (24h) | ISO 62 | 0.3% |

| Surface Resistance | GB/T 1410 | 10⁶~10⁸ Ω |

Processing and Installation

- Molding Process: Supports thermoforming (163-200℃), CNC engraving, laser cutting, minimum bending radius ≥10×sheet thickness • Connection Method: Recommended to use acrylic-specific UV glue or chloroform solvent welding, 0.5mm expansion joint required at seams • Installation Specification: Fix with stainless steel strips, avoid direct contact with metal brackets to prevent electrochemical corrosion

Precautions

• For cleaning, do not use alcohol or abrasive cleaners; neutral soapy water is recommended • For long-term outdoor use, additional UV protection coating is required to extend service life to over 15 years • During storage, avoid stacking heavy loads and maintain a well-ventilated and dry environment

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2