Introduction

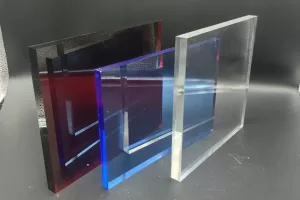

Acrylic sheets, prized for their optical clarity (92% light transmission) and versatility, are revolutionizing industries from aerospace to healthcare. With a global market expected to reach $8.37 billion by 2032 (CAGR 5.98%), this article explores cutting-edge applications, technical breakthroughs, and future trends driving adoption.

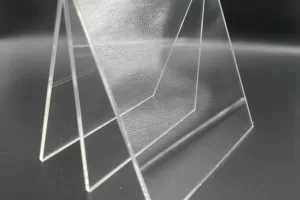

1. Aerospace and Defense

Cockpit Canopies and Windshields

• Material: Stretched acrylic (MIL-P-25690), offering 300% higher impact resistance than glass.

• Case Study: Lockheed Martin’s F-35 uses 12mm cast acrylic canopies, reducing weight by 400kg per aircraft.

• Innovation: Electrochromic acrylic for variable tinting, improving pilot visibility in extreme lighting conditions.

Satellite Optics

• Application: Telescope mirrors and solar panel covers.

• Advantage: UV stability (-80°C to 120°C) and low outgassing, critical for vacuum environments.

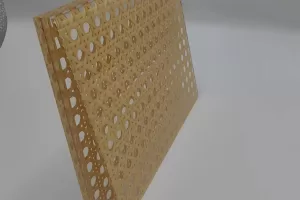

2. Medical and Biotechnology

Surgical Instruments and Implants

• Material: Medical-grade PMMA (ISO 10993-1), biocompatible and MRI-compatible.

• Case Study: Spinal fusion cages with porous acrylic coatings, promoting bone ingrowth (FDA-approved 2024).

• Technology: 3D-printed acrylic microfluidic chips for rapid COVID-19 testing, reducing analysis time from 24h to 1h.

Medical Devices

• Examples: Incubators (temperature resistance -40°C to 80°C) and dental prosthetics (custom color matching).

3. Architectural Innovation

Green Building Facades

• Application: Double-glazed acrylic panels with aerogel insulation.

• Performance: U-value 0.8 W/m²K, 50% better than traditional glass, installed at Salesforce Tower, San Francisco.

• Sustainability: 100% recyclable at end-of-life via chemical depolymerization (Trinseo’s Rho plant).

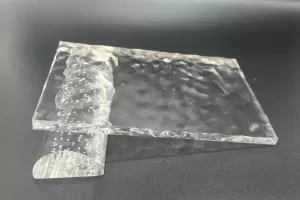

Dynamic Lighting Systems

• Technology: Light-diffusing acrylic (Optix® LD) for uniform LED illumination.

• Project: Dubai Expo 2020 pavilion, featuring 5,000m² of color-changing acrylic panels.

4. Renewable Energy and Electronics

Solar Energy Enhancement

• Innovation: Anti-reflective nano-coating, increasing panel efficiency by 8%.

• Data: 1m² acrylic cover generates 320kWh/year in Arizona’s desert climate.

Consumer Electronics

• Applications: Foldable phone displays (0.5mm ultra-thin acrylic) and smartwatch screens (scratch resistance 4H).

• Trend: Haptic feedback acrylic surfaces, enabling touch-sensitive controls in appliances.

5. Emerging Trends and Future Outlook

Bio-Based Acrylic

• Development: Braskem’s sugarcane-derived MMA, reducing carbon footprint by 50% compared to petroleum-based alternatives.

• Commercialization: Launch expected 2026, targeting packaging and consumer goods.

Self-Healing Acrylic

• Technology: Microcapsule-based coatings that repair scratches when heated to 60°C, extending product lifespan by 3 years.

AI-Driven Design

• Application: Generative design software optimizing acrylic structures for minimal material use (e.g., automotive light guides with 20% weight reduction).

Conclusion

Acrylic sheets continue to redefine possibilities across industries, driven by advancements in sustainability, performance, and manufacturing. As demand grows for lightweight, durable, and eco-friendly materials, acrylic’s role in innovation will only expand. For businesses, investing in acrylic solutions means aligning with both technological progress and environmental responsibility.

Sources: Röhm Group, Market Research Intellect, NASA Technology Reports