Introduction

Polyvinyl Chloride (PVC) sheets are a staple in construction, healthcare, and electronics due to their durability, chemical resistance, and cost-effectiveness. With the global PVC market projected to reach $80.92 billion by 2032 (CAGR 3.8%), understanding how to select the right PVC sheet is critical for project success. This guide covers material types, key parameters, installation best practices, and sustainability considerations.

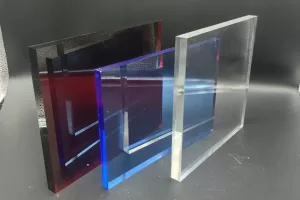

1. PVC Sheet Classifications

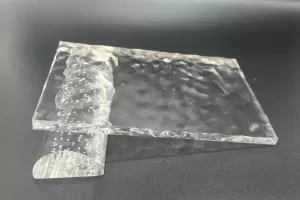

Rigid PVC (UPVC)

• Density: 1.38-1.45g/cm³, ideal for structural applications like pipes and window frames.

• Key Features: Flame retardant (UL94 V-0), low water absorption (<0.04%), and excellent insulating properties.

• Applications: Chemical tanks, electrical enclosures, and roofing membranes.

Flexible PVC

• Composition: Contains 10-40% plasticizers (e.g., phthalates), enabling flexibility.

• Key Features: Tensile strength 7-15 MPa, used in medical tubing and flooring.

• Considerations: Avoid in high-temperature environments (>60°C) to prevent plasticizer migration.

CPVC (Chlorinated PVC)

• Chlorine Content: 67%, offering higher heat resistance (continuous use up to 93°C).

• Applications: Hot water piping and industrial chemical processing.

2. Critical Selection Parameters

Mechanical Properties

• Impact Resistance: Rigid PVC Izod impact strength: 2.5 kJ/m² (ASTM D256), suitable for heavy-duty applications.

• Flexural Modulus: 3,400 MPa, ensuring structural stability in load-bearing panels.

Chemical Compatibility

• Resistant To: Acids (pH 2-12), alkalis, and salts; ideal for wastewater treatment facilities.

• Vulnerable To: Aromatic hydrocarbons (e.g., benzene) and strong oxidizing agents.

Fire Safety

• Oxygen Index: ≥32, self-extinguishing per UL94 V-0.

• Smoke Density: ≤200 (ASTM E662), critical for public buildings.

3. Installation and Maintenance Guide

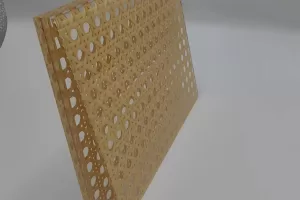

Cutting and Fabrication

• Tools: Carbide-tipped saw blades to prevent chipping; avoid high-speed cutting to reduce heat buildup.

• Joining Methods: Solvent welding (PVC cement) for watertight seams; mechanical fastening for large panels.

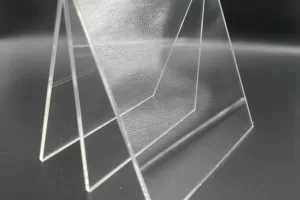

Installation Best Practices

• Expansion Gaps: Allow 5mm per 3m length to accommodate thermal expansion (coefficient: 7×10⁻⁵/°C).

• Fasteners: Use stainless steel screws to prevent corrosion in humid environments.

Long-Term Maintenance

• Cleaning: Mild detergent and soft brush; avoid abrasive pads that scratch the surface.

• Inspection: Check for discoloration or cracks annually, especially in outdoor applications.

4. Sustainability and Recycling

Environmental Impact

• Recycling Rate: 30% of post-consumer PVC is recycled, with technologies like Benvic’s mechanical recycling process achieving 90% purity.

• Carbon Footprint: 80% lower energy consumption compared to aluminum in construction applications.

Certifications to Look For

• ISO 11833-1: Ensures dimensional stability and mechanical performance.

• VinylPlus®: Guarantees compliance with EU environmental standards for recycled content.

5. Industry-Specific Case Studies

Construction: High-Rise Curtain Walls

• Material: 6mm rigid PVC with UV stabilizers.

• Result: 20% cost reduction vs. glass, installed at Dubai’s Marina Tower.

Healthcare: Isolation Rooms

• Material: 4mm flexible PVC with antimicrobial coating.

• Result: Meets ISO 10993-5 for biocompatibility, used in 50+ hospitals globally.

Electronics: Semiconductor Cleanrooms

• Material: Static-dissipative PVC (surface resistance 10⁶-10⁹Ω).

• Result: Prevents ESD damage in microchip manufacturing.

Conclusion

Selecting PVC sheets requires balancing mechanical strength, chemical resistance, and sustainability goals. By prioritizing certifications, proper installation, and maintenance, you can maximize durability and minimize lifecycle costs. For specialized applications, consult manufacturers like Georg Fischer for custom formulations.

Sources: Vinyl Institute, Coherent Market Insights, ASTM International