Introduction

Acrylic sheets, known for their exceptional transparency (92% light transmission) and durability, have become indispensable in industries ranging from architecture to healthcare. With a global market projected to reach $8.37 billion by 2032 (CAGR 5.98%), selecting the right acrylic sheet requires careful consideration of material properties, application requirements, and industry standards. This guide provides a step-by-step framework for choosing acrylic sheets, supported by technical data and real-world案例.

1. Material Types: Cast vs. Extruded Acrylic

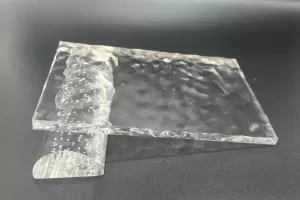

Cast Acrylic

• Production Process: Manufactured by pouring liquid monomer into molds, resulting in higher molecular weight.

• Key Advantages: Superior chemical resistance (resistant to alcohols and weak acids), better optical clarity, and suitability for complex fabrication like laser engraving.

• Applications: Aquariums, high-end signage, and medical devices (ISO 10993-5 certified for biocompatibility).

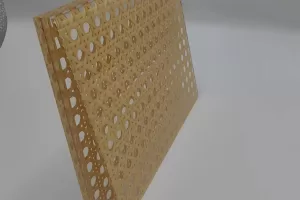

Extruded Acrylic

• Production Process: Melted resin is pushed through dies, creating uniform thickness sheets.

• Key Advantages: Lower cost, faster production, and better dimensional stability for large panels.

• Applications: Architectural glazing, retail displays, and protective barriers.

Comparison Table

| Property | Cast Acrylic | Extruded Acrylic |

| Thickness Tolerance | ±10% (≥5mm) | ±5% |

| Impact Resistance | 17x glass | 10x glass |

| UV Stability | 10+ years outdoor | 5-7 years outdoor |

2. Key Parameters for Selection

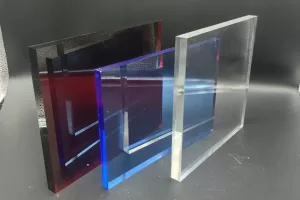

Optical Properties

• Transparency: Verify haze value (ASTM D1003) <1% for critical applications like display cases.

• Color Consistency: Check for uniform pigment distribution, especially in tinted sheets (e.g., RGB lighting applications).

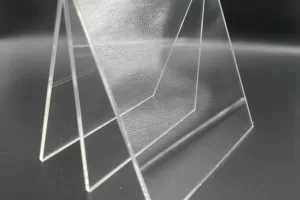

Mechanical Strength

• Thickness: Indoor decorative use (2-5mm); structural applications (8-25mm). For example, aircraft canopies use 12mm cast acrylic for impact resistance.

• Flexural Modulus: 3,100 MPa (cast) vs. 2,800 MPa (extruded), affecting load-bearing capacity.

Environmental Adaptability

• Temperature Range: Continuous use from -40°C to 80°C; avoid prolonged exposure to temperatures exceeding 90°C to prevent warping.

• Chemical Resistance: Resistant to diluted acids but vulnerable to ketones (e.g., acetone).

3. Application-Specific Recommendations

Architectural Glazing

• Requirement: UV stabilization and thermal insulation.

• Solution: 10mm UV-resistant cast acrylic with a 30-year non-yellowing warranty (e.g., ACRYLITE® GMS).

Medical Devices

• Requirement: Biocompatibility and easy sterilization.

• Solution: FDA-compliant cast acrylic (ASTM F3087) for surgical instrument trays.

Renewable Energy

• Requirement: High light transmission for solar panels.

• Solution: Anti-reflective coated acrylic (8% efficiency improvement).

4. Common Mistakes to Avoid

• Choosing Based on Price Alone: Extruded acrylic may cost 30% less than cast but lacks chemical resistance for laboratory use.

• Ignoring Thickness Tolerance: Inconsistent thickness (±0.5mm) can cause uneven thermal expansion in large installations.

• Overlooking Certification: Ensure compliance with ASTM D4802 for general use and ISO 10993 for medical applications.

5. Expert Tips for Longevity

• Surface Protection: Use microfiber cloth with mild soap; avoid abrasive cleaners to prevent scratches.

• Installation: Allow 3mm expansion gap per meter to accommodate thermal movement.

• Recycling: Look for manufacturers offering take-back programs (e.g., Röhm’s PLEXIGLAS® recycling initiative).

Conclusion

Selecting the right acrylic sheet involves balancing optical, mechanical, and environmental requirements. By leveraging industry standards, certified products, and application-specific insights, you can ensure optimal performance and cost-effectiveness. For complex projects, consult with suppliers like Acrylite or Plexiglas for custom solutions.

Sources: ASTM International, Market Research Intellect, Röhm Group Case Studies