+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

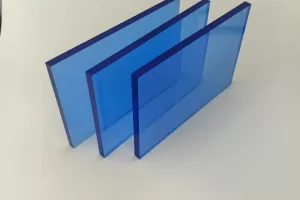

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

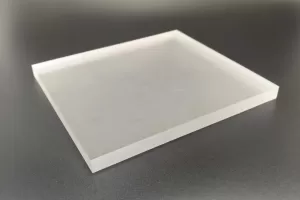

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

TOP 10 Acrylic Sheets Manufacturers in 2026 (2025 Review & Global Ranking)

Introduction

The global acrylic sheet market landscape in 2025-2026 is defined by robust demand, propelled by sustainability initiatives and technological innovation. A pivotal industry shift is the accelerated transition toward green and recycled PMMA, which has evolved from a niche offering into a mainstream competitive prerequisite. The market remains highly consolidated, with dominance secured by vertically integrated technological giants. The top three industry leaders anchoring this landscape are Mitsubishi Chemical Group, Röhm GmbH, and Plaskolite.

Acrylic sheet: a high performance polymer used in demanding applications

Acrylic sheet is a transparent thermoplastic polymer, formerly known as polymethyl methacrylate (PMMA), which is an important engineering material with excellent optical transparency, excellent durability and excellent versatility. It is a strong and light substitute for traditional glass, which has excellent impact resistance (up to 10 times strength) and transmits more than 92% visible light at the same time. Its excellent weather resistance and ultraviolet degradation resistance make it a reliable choice for indoor and outdoor use.

Major application Fields:

It has a wide range of application, across industries. Key areas included:

- Building and Construction: Skylights, curtain walls, noise barriers and sanitary ware.

- Signage & Display: Illuminated signs, retail displays, exhibition structures, and POP fixtures.

- Transportation: Automobile headlight lenses, aircraft windows and internal components.

- Industry and medical treatment: Machine protective devices, protective barriers, medical equipment casings and laboratory equipment.

Main material Advantages:

The advantages of this new material are caused by a series of key benefits.

- Lightweight and strong: Much lighter than glass and complete in structure.

- Easy to manufacture: It can be easily cut, drilled, thermoformed and laser cut, making complicated designs.

- Design flexibility: There are many colors, translucency, textures and thicknesses to choose from.

- Durability & Safety: High impact resistance reduces breakage risk, and it can be engineered to be shatter-resistant.

Nowadays, with the manufacturers promoting high-quality recycled materials and bio-based PMMA technology, this material continues to develop in the direction of sustainable development, strengthening its role as a future solution for modern design and engineering challenges.

Comparison Table of Top 10 Global Manufacturers in 2026

| Ranking | Company Name | Headquarters | Key Brand(s) | Primary Market Focus |

| 1 | Mitsubishi Chemical Group | Tokyo, Japan | Shinkolite®, Acrypet® | Automotive, Electronics, Signage |

| 2 | Röhm GmbH | Darmstadt, Germany | PLEXIGLAS® | Architecture, Automotive, Lighting |

| 3 | Plaskolite, LLC | Columbus, Ohio, USA | OPTIX®, Acrylite® | Signage & Display, Glazing, Retail |

| 4 | Beijing Jingruite New Materials Co., Ltd. | Beijing, China | Jingruite | Advertising & Display, Furniture, Sanitaryware |

| 5 | Schweiter Technologies (3A Composites) | Steinhausen, Switzerland | Crylux®, Correx® | Architecture, Interior Design, Fine Art |

| 6 | Chi Mei Corporation | Tainan, Taiwan | CM-ACRYPOLY® | Electronics, Appliances, Automotive |

| 7 | Double Elephant Optical Material Co., Ltd. | Suzhou, China | — | Signage, Bathroom, Furniture |

| 8 | Jolywood (Suzhou) Sunwatt Co., Ltd. | Suzhou, China | — | Solar, Building Integrated PV (BIPV) |

| 9 | Unigel S.A. | São Paulo, Brazil | Acrilex® | South American Market (Signage, DIY) |

| 10 | Perspex International | Darwen, UK | Perspex® | UK & Europe (Glazing, Retail, Safety) |

The Detailed List

1.Mitsubishi Chemical Group

- Company profile: As a global chemical giant, Mitsubishi Chemical’s performance materials department is a giant in the PMMA industry. Its scale and integration, from PMMA monomer as raw material to finished plate, provide unparalleled supply chain stability.

- Production capacity: It operates some of the world’s largest integrated acrylic sheet production facilities, with a global annual capacity exceeding 500,000 metric tons.

- Key Products: A full portfolio including high-heat resistant casting plates (Shinkolite), extruded sheets, and pellets for molding.

- The reason for ranking first: Their dominant position stems from vertical integration, large-scale R&D investment and real global footprint, providing consistent high-specification new materials for global automobile original equipment manufacturers, electronics giants and general industries.

2. Lem Limited

- Core Advantage: Roma is synonymous with plexiglass brand. For decades, this name has become the industry standard for quality and innovation. This unparalleled brand value in architecture and high-end applications is its core advantage.

- Innovation 2025: The company redoubled its efforts in sustainable development with its “pro circular” series, which is a breakthrough in the quality of post-consumer recycled acrylic acid (PCR). They also improved the digital printing compatibility for customized building surfaces.

3. Plath Colet Limited liability company

- Company Profile: As the largest acrylic sheet manufacturer in North America, Plaskolite is famous for its market flexibility and extensive distribution network. After acquiring acrylic brand, it consolidated its product range.

- Key Products: A comprehensive mix of extruded (OPTIC) and cast acrylic sheets, with a strong focus on value-added products like anti-static, UV-filtering, and recycled-content sheets.

- Why they are a leader: Their deep understanding of the North American signage, retail, and glazing markets, combined with responsive customer service and strategic acquisitions, keeps them at the forefront.

4. Beijing Jingruite New Materials Co. Ltd.

- Company Overview: Established in 2008, Beijing Jingruite New Materials Co. Ltd. represents the rise of specialized Chinese manufacturers in the global acrylic sheet market. The company has developed into an important comprehensive enterprise, integrating production, processing and export business. Jingruite has 17 years of industry experience and operates three production bases, focusing on providing acrylic products with high transparency and high gloss.

- Production Capacity: The company has six dedicated production lines spanning its manufacturing base, which shows that it attaches great importance to mass production and product diversification to meet various market demands.

- Key Products: Their portfolio includes a wide range of acrylic sheets, such as Color Acrylic Sheets, Acrylic Mirror Sheets, Sanitary (Bathtub) Acrylic Sheet, Noise-Barrier Acrylic Sheet, and Light Guide Plate (LGP) Acrylic Sheet, alongside PVC foam sheets.

- Why they are a Top Contender: Jingruite’s strength lies in its competitive Factory-Direct Pricing model and exceptional flexibility. They effectively cater to the needs of small and medium-sized buyers by providing low MOQs (minimum order quantity) and comprehensive customization options in size, thickness and color. This strategy, combined with value-added processing services like cutting, engraving, and polishing, makes them an attractive one-stop solution for projects in advertising, display, furniture, and sanitaryware, particularly for clients prioritizing cost-efficiency and tailored services without sacrificing basic quality.

5. Schneider Technology Company (3A Composites)

- Core Advantage: 3 A Composites is the master of engineered composite materials. Their Crylux acrylic sheets are usually the first choice for architects and designers seeking advanced aesthetics, such as matte finish, metal appearance and excellent facades weather resistance.

- Innovation 2025: Continue to introduce designer series and special surface textures, and integrate acrylic with other materials to push the boundaries of creative applications.

6. Mei group

- Company profile: Chimei’s PMMA division is a major player in global synthetic resin, especially in the Asian market. They are key supplier in the supply chain of consumer electronics products.

- Production Capacity: One of the largest producers of MMA/PMMA in the world, achieving remarkable economies of scale.

- Main Products: High fluidity optical grade granules and sheets for LED light guides, TV diffuser and automobile lighting.

7. Double Elephant Optical Material Co. Ltd.

- Company Overview: A leading force in China’s acrylic sheet industry, Double Elephant has grown into a major global exporter, known for its large-scale production of cast acrylic.

- Primary Market: They are the main suppliers of global signs, bathroom equipment (bathtub) and furniture industries, mainly competing in cost competitiveness and reliable mass supply.

- Global Role: Their rise reflects the competitive pressure of global acrylic market and the diversification of supply chain.

8. Hollywood (Suzhou) Solar Cells Co., Ltd.

- Core Advantage: Jolywood focuses on the application of acrylic acid and polymer in solar photovoltaic industry, opening up a unique niche market. Their specialty is to protect the acrylic sheet and packaging materials of solar panels.

- Innovation Focus: They promote the progress of durability, light transmittance and anti-PID (potential induced degradation) characteristics, and directly contributing to the efficiency and life of solar panels.

9. Nigel Ltd.

- Company profile: As a major chemical manufacturer in Latin America, Nigel occupies a nearly dominant position in the acrylic sheet market in this region with its Acrilex brand.

- Key Advantage: Local manufacturing in Brazil provides tariff advantages and reliable supply for the South American market, insulating customers from global logistics volatility and currency fluctuations.

10. Plexiglass International Company

- Company Overview: Steeped in history as the original UK developer of acrylic (Perspex), the company remains a respected manufacturer and distributor focused on the UK and European markets.

- Niche market: They are good at providing professional products, including various colors, mirror panel and texture options, suitable for retail, point-of-sale and security screening applications, providing great flexibility for small projects.

How to Choose the right acrylic sheet manufacturer ?

- Quality Standards: always verify relevant certifications (for example. ISO 9001 and ISO 14001) For specific applications, please refer to the data sheet of material property for information on light transmittance (> 92% optical transparency), impact strength and ultraviolet stability (e.g. Yellowing resistance).

- Cast vs. Extruded: This is the fundamental choice.Choose to cast acrylic resin to obtain excellent chemical resistance, optical quality and fabric properties (thermoforming and polishing). It is very suitable for aquariums, sanitary wares, high-end displays and machined parts.For cost-sensitive mass applications, consistency and large-size plates are key. Please choose extruded acrylic acid. Ideal for basic signs, glass and protective barriers.

- Logistics and Support: Assess the ability of manufacturer or distributor to deliver goods to your location reliably. Consider lead times, MOQs and technical support services. A global giant may provide supply security, while a regional participant may provide faster and more personalized service.

Acrylic Sheet Market Trends 2026: Global Industry Analysis and Forecast

Sustainability and recovery of acrylic resin

The transition from linear to circular economy models is the defining trend. In 2025, major players like R ö hm and Mitsubishi made significant strides in commercializing PMMA recycling via depolymerization (chemical recycling), which restores monomer to virgin-like quality. This kind of “green acrylic acid” is no longer a high-quality product, but an essential option in the bidding in Europe and North America. ISCC PLUS and other quality balance certifications have become the key to 2B marketing.

The growth of application

Beyond traditional signage and glazing, demand is surging in specific sectors: Acoustic Barriers for highways and urban areas use cast acrylic for durability and sound insulation. Medical Protective Barriers remain a steady application. The fastest growing are high-end interior design (decorative board, luminous ceilings) and BIPV (Building Integrated Photovoltaic), in which acrylic resin is used as a protective light-transmitting layer.

Power of supply chain

In 2025, the prices of key raw new material (MMA) were relatively stable after previous fluctuations. However, geopolitical factors and regional energy costs continue to exert different price pressures in Asia, Europe and America. This strengthened the regionalization strategy, and companies such as Nigel and Plaskolite benefiting from its localized production.

Frequently asked Questions

Q: Who is the world’s largest manufacturer of acrylic sheets?

A: Based on its total production capacity and global market coverage, Mitsubishi Chemical Group (Japan) is widely regarded as the world’s largest acrylic sheet and resin manufacturer.

Q: Is Chinese acrylic sheet good quality?

A:The quality of Chinese acrylic sheets varies, as with any manufacturing region. Acrylic sheets produced by leading manufacturers in China, such as Beijing Jingruite and Shuangxiang, conform to international standards and are widely used in commercial and industrial fields. Companies like Jingruite have built a reputation on providing cost-effective solutions that do not affect core functions and reliable products for signs, monitors and furniture. It is essential to purchase from reputable and reputable suppliers, who use high-quality raw materials and clearly specify the quality grade and certification required for the project.

Q: What are the difference between acrylic, plexiglass and ordinary glass?

A: Acrylic (called polymethyl methacrylate or PMMA in chemistry) and plexiglass refer to the same plastic material. The key difference is versus regular glass: acrylic is much lighter (about half the weight), significantly more impact-resistant (5-10 times stronger), and easier to cut and shape, while offering similar light transmittance (> 92%). However, acrylic is soft and easy to scratch, and its heat resistance is lower than that of glass. Glass is harder, more scratch resistant and heat resistant, but heavier and more brittle. (Source: Manufacturer technical data sheets and material science handbooks).

Q : How to distinguish between cast acrylic and extruded acrylic? Which one should I choose?

A: The core difference is the manufacturing process, which determines performance. Casting acrylic resin is made by casting liquid resin between glass plates. It is superior in manufacturing: it has better chemical resistance, thermoformability and optical transparency, and can be processed and polished into finer edge. It’s the choice of aquariums, high-end sign, sanitary ware and complex manufacturing. Extrusion of acrylic resin is made by pushing molten material through dies. It is more cost-effective, can be used for larger plates and has good consistency, but it is softer and more prone to stress cracking in the manufacturing process. It is an ideal choice for flat glass, foundation signs and protective barriers. (Source: Industry manufacturing standards and fabricator guidelines from companies like Plaskolite and Röhm).

Q: What do the terms “plot casting” and “continuous casting” mean?

A: Both of them are subtypes of cast acrylic, but their production scales and consistency are different. Unit casting is a batch process, in which each piece is cured between glass plates separately. It is considered as an advanced product, with the highest molecular weight, best chemical resistance and the best stability, and is suitable for deep molding and polishing. Continuous casting is a more automatic roll-to-roll process. It offers a good balance of cast acrylic properties (better than extruded) at a lower cost and with more consistent thickness than cell cast, making it excellent for high-volume production of items like sanitaryware and standard displays. (Source: Acrylic fabricating industry publications and supplier technical notes).

Conclusion

In 2026, the global acrylic sheet market is dynamic, which is formed by the necessity of sustainable development and diversified application needs. The top 10 manufacturers listed here lead the development of the industry through scale, innovation and regional advantages. From Mitsubishi’s global dominant position to Roma’s sustainable breakthroughs and Plaskolite’s regional leading position, each one plays a vital role.

Your selection of supplier should be consistent with your priority: key quality of the project, cost competitiveness or sustainable procurement. We strongly recommend contacting at least two manufacturers from this list for material samples and data sheets, so as to evaluate which product is best for your specific needs before making a purchasing decision.

Posts Categories

- Blogs17

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2