+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

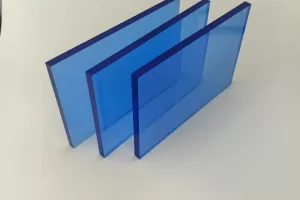

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

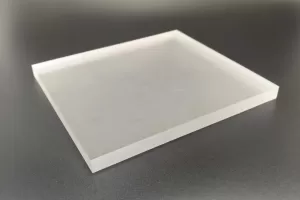

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

What is a V0 flame retardant acrylic board and why Should you consider using it in your project?

In applications where safety, beauty and durability are essential, one material stands out: flame retardant acrylic sheet. For projects in buildings, public transportation or high-end lighting, the ability to order customized sizes of acrylic panels with a V0 flame retardancy is a key decision. This guide provides a detailed overview of V0-grade acrylic boards, explaining their advantages, specifications and applications to help you make an informed choice.

1. What is a V0 flame retardant acrylic sheet?

Flame-retardant acrylic board is a transparent or colored plastic board made from PMMA (polymethylmethacrylate), which is modified with additives to be flame retardant. Unlike standard acrylic, it is engineered to self-extinguish once the ignition source is removed. The “V0” grade is the highest grade under the flammability standard of UL94 plastic. This means that in a vertical combustion test, the material will stop burning within 10 seconds after the flame is removed, and there are no burning droplets. This makes V0 flame-retardant acrylic board an essential product in the environment where controlling fire spread is very important.

Core Technology Breakdown:

Basic materials: 100% pure PMMA. This ensures optimal clarity, strength, and consistent performance, directly impacting the 92% light transmittance.

Manufacturing technology: precision extrusion. This makes the thickness uniform (tolerance of 0.1 mm) and produces very large panels, making it possible to supply acrylic plates with customized size for major items.

Key Modifications: Nano-scale flame retardant creates a protective carbon layer, which insulates the material and cuts off oxygen, resulting in flame extinction. The ultraviolet stabilizers is added for outdoor weatherability.

2.Key Advantages of V0 Acrylic Sheets

The benefits of choosing V0 grade flame retardant acrylic sheet far exceed the basic fire safety .

Enhanced life safety: V0-grade materials divide the fire risk, which provides vital extra time for evacuation in public places such as airports and subways.

Excellent optical performance and durability: 92% light transmittance (equivalent to optical glass) and impact strength 10 times higher than that of ordinary glass, providing clarity and safety, but not fragile. Its density is 1.19 g/cm and its weight is about half that of glass.

Excellent weather resistance: it can work in a wide temperature range (-40 degrees Celsius to 90 degrees Celsius), and it is resistant to yellowing, ensuring long-term outdoor beauty. Driven by stricter safety regulations, the global market of flame retardant plastics for building is growing. (source: Research Report on Flame Retardant Plastics Market).

Maximum design flexibility: the ability to customize the size of acrylic board (up to 3000 mm x 9000 mm) and thermoform it into complex shapes opens up the possibility of seamless and large-scale design.

3. Overview of product Specifications

The following are the key performance indexes of high quality V0 flame retardant acrylic sheet.

Optical transmittance: 92%

Density: 1.19g/cm3.

Impact strength: > ten times that of common glass.

Service Temperature Range: -40℃ to 90℃ (long-term use).

Flame Retardancy Rating: V0 (per UL 94 standard).

maximum Sheet Size: 3000 mm x 9000 mm.

These specifications are the result of advanced manufacturing and strict quality control, ensuring reliability of key applications.

4. Where is V0 acrylic sheet used

The combination of safety, transparency and moldability makes this kind of flame retardant acrylic sheet an indispensable material in various industries.

Building Materials: internal partitions, railings and skylights used in airports, shopping malls and offices that require transparency and fire safety.

Transportation: It is essential for the internal glass and partition of trains and subways, where the highest fire safety standards are required.

High-End Lighting: Serves as LED light covers and diffuser in commercial and industrial fixtures where a V0 rating is often mandatory.

Professional Applications: Ideal for museum display cases and laboratory equipment screens to protect the contents from fire and impact.

Frequently Asked Questions

Q: Is 1: V0 flame-retardant acrylic board completely fireproof?

A: No. “Flame retardant” and “fire prevention” are different. V0-grade plate is designed to resist ignition and self-extinguish quickly, thus slowing down the fire spread. It will degrade at a continuous high temperature.

Q: Can you make these sheets after purchasing?

A: Yes, acrylic can be cut and made by professionals. However, ordering custom-sized acrylic sheets from the manufacturer can ensure perfect edges and maintained material characteristics.

Q: What is the cost compared with the standard acrylic or glass?

A: Because of special additives, it is more expensive than standard acrylic resin, but it is usually more cost-effective than special fireproof glass, especially considering its impact resistance and light weight.

In summary, selecting a V0-rated flame retardant acrylic sheet and utilizing the option for an acrylic sheet custom size is a strategic decision that balances critical safety requirements with superior material performance and design flexibility. It is the best material solution for modern engineering, and in modern engineering, security is uncompromising.

Posts Categories

- Blogs22

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2