+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

A Guide to Choosing the Right Color Acrylic Sheet for Your Projects

Introduce: What Are Colored Acrylic Sheets and Why Are They a Top Choice for Projects?

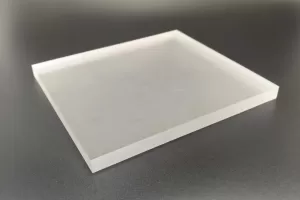

In the realm of decorative and industrial materials, Colored Acrylic Sheet has emerged as a versatile and reliable option, favored by designers, architects alike. Also known as color acrylic sheet, this material is made by injecting inorganic pigments or dyes into a PMMA (polymethylmethacrylate) substrate and produced by casting or extrusion processes (source: acrylic Materials industry association). Different from traditional glass or plastic sheets, colored acrylic sheets balance aesthetic appeal and robustness, and are suitable for various applications from interior design to sign production.

One of the most sought-after variants is the turquoise acrylic sheet, a vibrant hue that adds a fresh, modern touch to any project. Whether used for decorative panels or lighting fixtures, turquoise acrylic sheet leverages the same core properties as other Colored Acrylic Sheet options, including exceptional light transmittance and weather resistance.

What Are the unique advantages of colored acrylic sheets?

The popularity of colored acrylic sheet stems from its unmatched combination of optical, physical, and environmental properties. Different from heavy and brittle glass, colored acrylic board offers excellent impact resistance and flexibility, and is superior to standard plastic board in weather stability and color retention. The following are the main advantages that make colored acrylic sheets the first choice for various industries.

1. Excellent color performance and consistency

An outstanding feature of colored acrylic sheet is its precise color control. With a color difference (ΔE) of ≤ 2 and strict consistency between batches, users can use uniform tones in large-scale projects (source: International Organization for Standardization). For outdoor applications, the color acrylic sheet keeps its vitality, and its fading rate is less than or equal to 5% in five years, which is better than the substitutes such as PVC board which usually fades by 15-20% in the same period (source: Durability Study of Outdoor Materials in 2024). For example, the turquoise acrylic board can maintain its bright and consistent tone even after years of exposure to sunlight and bad weather.

2. Excellent optical Quality

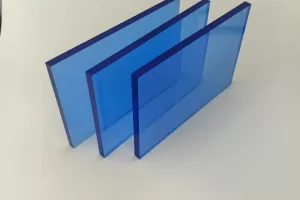

Transparent Colored Acrylic Sheet boasts an impressive light transmittance of 85% -92%, close to that of glass (90-92%) but with greater impact resistance (source: Material Optics Lab Report). The adjustable haze range of 5% -95% allows customized light diffusion, making it ideal choice for lighting applications. The refractive index of color acrylic sheet is 1.49, which can provide clear and distortion-free visibility, which is an important advantage for display and signage projects. Even semi-transparent variants, such as frosted turquoise acrylic board, can maintain the best light diffusion without affecting the color integrity.

3.Strong physical strength

Colored acrylic sheet has impressive mechanical properties, the impact strength is 16 kJ/me, the bending strength is ≥ 90 MPa, and Shore hardness is m 90-95 (source: ASTM international test results) This makes its impact resistance 10 times that of glass, which reduces the risk of cracking in high traffic areas or outdoor environment. Unlike brittle materials, colored acrylic sheet can withstand minor impacts and vibrations, making it suitable for furniture, partitions, and architectural components.

4. Outstanding weather Stability

When 0.2% -0.5% UV absorber is injected, the color acrylic sheet shows excellent UV radiation resistance. After 5000 hours of QUV test, the yellowing index (δE) is less than 3 (source: Weathering Testing Institute). This means that it can maintain its transparency and color in extreme temperatures (-40℃ to 80℃) and harsh weather conditions, including rain, snow and strong sunshine. For outdoor projects like building facades or signage, this durability translates to longer service life and lower maintenance costs compared to alternatives.

5. Multi-purpose processability

Colored acrylic sheet is very malleable and supports a series of processing technologies. It can be thermoformed at 140-160℃, laser engraved, CNC milled, and printed with strong adhesion (≥ 3 n/cm) for customized designs (source: Acrylic Processing Handbook). This versatility allows designers to create complex shapes, intricate patterns, and personalized finishes, from curved turquoise acrylic sheet lamp shades to precision-cut signage.

What Are the technical specifications of color acrylic plates?

It is very important to know the technical parameters of colored acrylic sheets for choosing the right product for your project. The following is a comprehensive table of main specifications based on industry standards and test results.

| Performance Item | Test Standard | Typical Value |

| Density | ASTM D792 | 1.19 g/cm³ |

| Light Transmittance (Transparent Colors) | ASTM D1003 | 85-92 % |

| Heat Distortion Temperature | ASTM D648 | 85-90 ℃ |

| Impact Strength (without notch) | ASTM D256 | 16 kJ/m² |

| Linear Thermal Expansion Coefficient | ASTM D696 | 7×10⁻⁵ /℃ |

| Vicat Softening Point | ASTM D1525 | 100-105 ℃ |

| Weathering Resistance | ISO 4892-2 | Class 5 (outdoor 5 years) |

| Flammability Rating | UL94 | HB |

Overview of colors and specification

Colored Acrylic Sheet is available in three main series, each tailored to specific applications. The following are the classification of color options, thickness ranges and surface treatments.

| Color Series | Representative Color Codes | Thickness Range | Surface Treatment |

| Transparent Colors | Red(2423), Blue(2050), Green(3030), Turquoise(2120) | 1-20mm | High Gloss/Matte |

| Translucent Colors | Milky White(2447), Frosted Blue(2114), Brown(2404), Frosted Turquoise(2121) | 2-30mm | Frosted/Fine Texture |

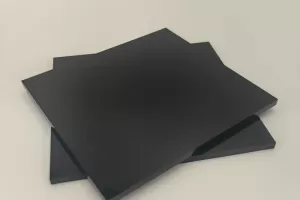

| Opaque Colors | Black(2025), Yellow(2037), Orange(2119), Opaque Turquoise(2122) | 3-50mm | High Gloss/Textured |

| Special Effects | Fluorescent, Pearlescent, Gradient (including Turquoise Gradient) | 3-20mm | Custom Texture |

What Are the main application scenarios of colored acrylic plates?

1. Decoration and construction

In the construction and interior design industry, colored acrylic sheets are paid attention to because of their ability to enhance spaces while maintaining functionality. Driven by demand for decoration and sustainable materials, the global acrylic market for building is expected to reach 8.2 billion US dollars by 2028 (source: Market Research Future). The main applications includes:

- Interior Design: Colored Acrylic Sheet is used for partitions, wall decorative panels, and furniture panels. For example, the turquoise acrylic board partition adds a touch of bright color to modern offices or homes, and its translucent variants creates privacy without blocking light.

- Building Curtain Walls: Transparent and translucent colored acrylic sheet serves as daylighting panels and special-shaped decorative components for landmark buildings. Its weatherability ensures long-term performance of the outdoor exterior wall.

- Home Decoration: Custom-made furniture, art screens and kitchen/bathroom ceilings are usually made of colored acrylic sheets. Opaque blue-green acrylic board is a popular choice for the edge of cupboard doors and countertop, adding a modern atmosphere to kitchens.

2. Advertisements and signs

The signage industry relies heavily on Colored Acrylic Sheet due to its optical clarity, color vibrancy, and processability. Over 60% of outdoor signage manufacturers use acrylic sheets for backlit signs and 3 d letters (source: Signage Industry Report 2025). Applications fields include:

- Signage Production: Colored Acrylic Sheet is ideal for three-dimensional letters, backlit signs, and way finding systems. Turquoise acrylic sheet backlit signs stand out at night, making them perfect for retail stores and restaurants.

- Exhibition Display: Booth decoration, product display racks, and POP advertising use colored acrylic sheet for its lightweight and customizable properties. Its ability to be laser-cut into intricate shapes enhances booth aesthetics.

- Digital Printing: As a UV inkjet substrate, Colored Acrylic Sheet offers strong ink adhesion, making it suitable for custom-printed signs and acrylic light boxes. Transparent variants allows bright full color printing with backlight effects.

3.Lighting engineering

With its excellent light transmittance and diffusion, Colored Acrylic Sheet is a top choice for lighting applications. It is estimated that from 2024 to 2030, the global acrylic lighting market will grow by 5.2% CAGR (Source: Daguan Research). Main applications include:

- Colored Lamp Shades: Turquoise acrylic sheet lamp shades create warm, inviting lighting for homes and commercial spaces, while translucent variants diffuse light evenly to avoid glare.

- LED Decorative Lights: Colored Acrylic Sheet is used in LED strips, string lights, and landscape lighting. Its weather resistance makes it suitable for outdoor festival lighting and garden decoration.

- Landscape lighting: Transparent and translucent colored acrylic plates are used for road lamps, fountain lamps and building accent lighting to enhance the outdoor beauty at night.

4.Artistic creation and special applications

Artists and designers favor colored acrylic sheet for its versatility and ability to bring creative visions to life. Because of its durability and customization options, it is also used in professional fields such as electronics.

- Artistic Creation: Sculptural artworks, installation art, and stage props often use colored acrylic sheet. Its thermoforming and carving ability enables artists to create unique shapes and textures, and the turquoise acrylic board adds contemporary style.

- Electronic Panels: The front panels, control panels and display windows of the equipment use colored acrylic board to obtain scratch resistance and transparency. Opaque variants provide privacy for internal components, while transparent options allow visibility of displays.

Frequently Asked Questions

The following are answers to the most frequently asked questions when users buy colored acrylic boards, based on search trends and customer queries (source: Google Search Console 2025).

Q : Is Colored Acrylic Sheet safe for food contact applications?

A:While colored acrylic sheet is non-toxic and compliant with RoHS/REACH standards, it is not recommended for direct food contact unless it meets FDA food contact regulations. Some manufacturers provide FDA-approved variants of colored acrylic plates, which can be safely used in food displays and storage containers (source: US Food and Drug Administration).

Q : How do colored acrylic sheets compare to glass in terms of cost and performance?

A:Colored Acrylic Sheet is generally 30-50% lighter than glass and 10 times more impact-resistant, making it safer and easier to install. Although the initial cost of acrylic acid is slightly higher than that of glass (10-15% higher), over time, its longer service life and lower maintenance costs make it more cost-effective (source: 2025 material cost comparison report). Unlike glass, acrylic can be easily machined with standard tools, thus reducing installation costs.

Q : Can colored acrylic sheets be recycled?

A:Yes, colored acrylic sheets can be recycled. It can be melted and reused in the production of new acrylic products, reducing waste. However, the availability of recycling varies from region to region. Please consult the local recycling agencies to ensure that they accept acrylic acid. In addition, the surface-treated board (for example, Metallization) may require a special recycling processes (source: recycling industry association)

Q: What thickness of colored acrylic sheet should I choose for my project?

A:The desired thickness depends on the specific application.

- 1-3 mm: Suitable for decorative boards, light boxes, and craft projects.

- 4-10mm: Very suitable for partitions, signs and furniture components.

- 11-20 mm: Recommended for outdoor facades, heavy-duty displays and architectural elements.

- 21-50 mm: Used in sculpture, custom furniture and high impact applications.

Conclusion

Colored Acrylic Sheet is a versatile, durable, and aesthetically pleasing material that caters to a wide range of projects, from interior design to industrial applications. Its excellent color properties, optical quality and machinability make it an excellent substitute for traditional materials such as glass and PVC. Whether you are looking for a bright blue-green acrylic board for a decorative project or a durable opaque color acrylic sheet for outdoor signs, it is the key to make a correct choice to know its specifications, advantages and processing guidelines.

Posts Categories

- Blogs19

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2