+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

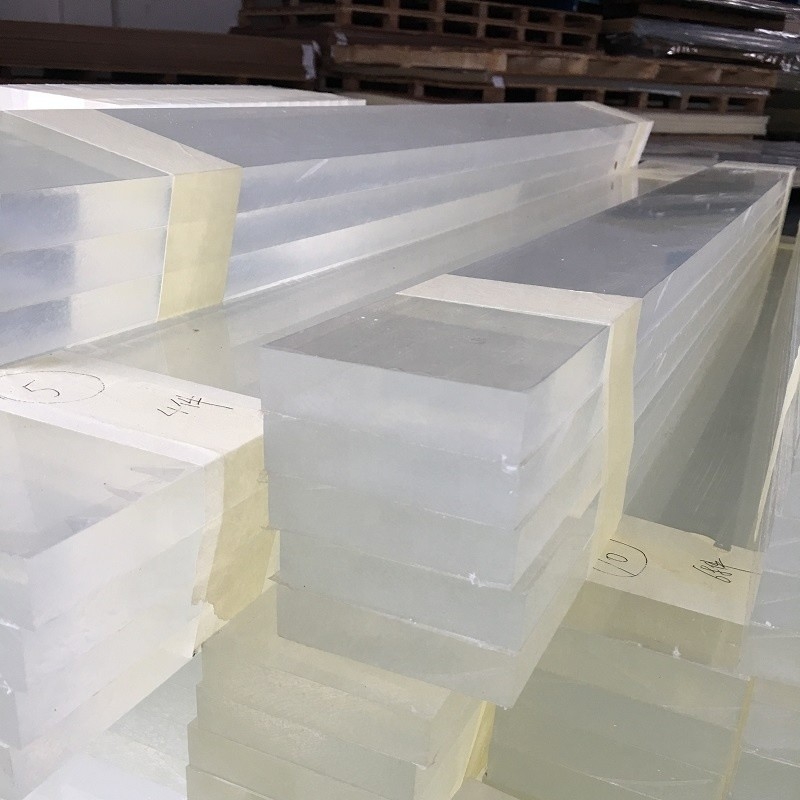

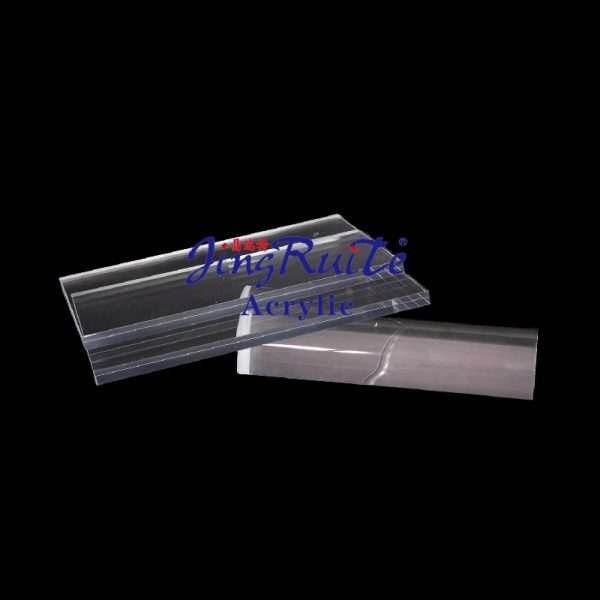

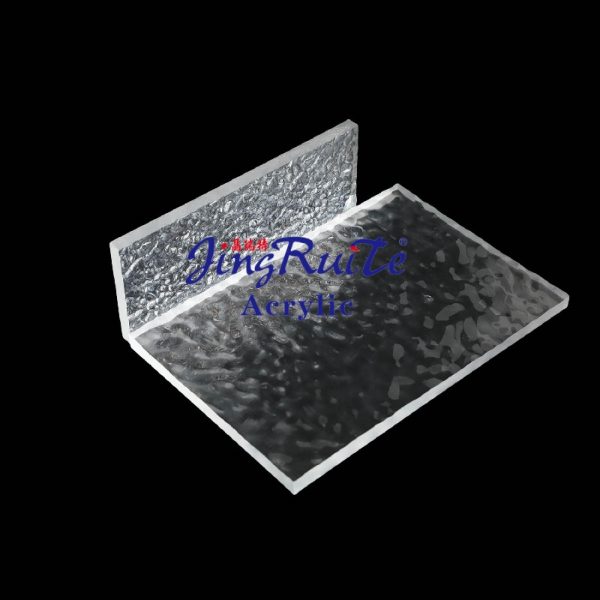

Impact Resistant Acrylic Sheet

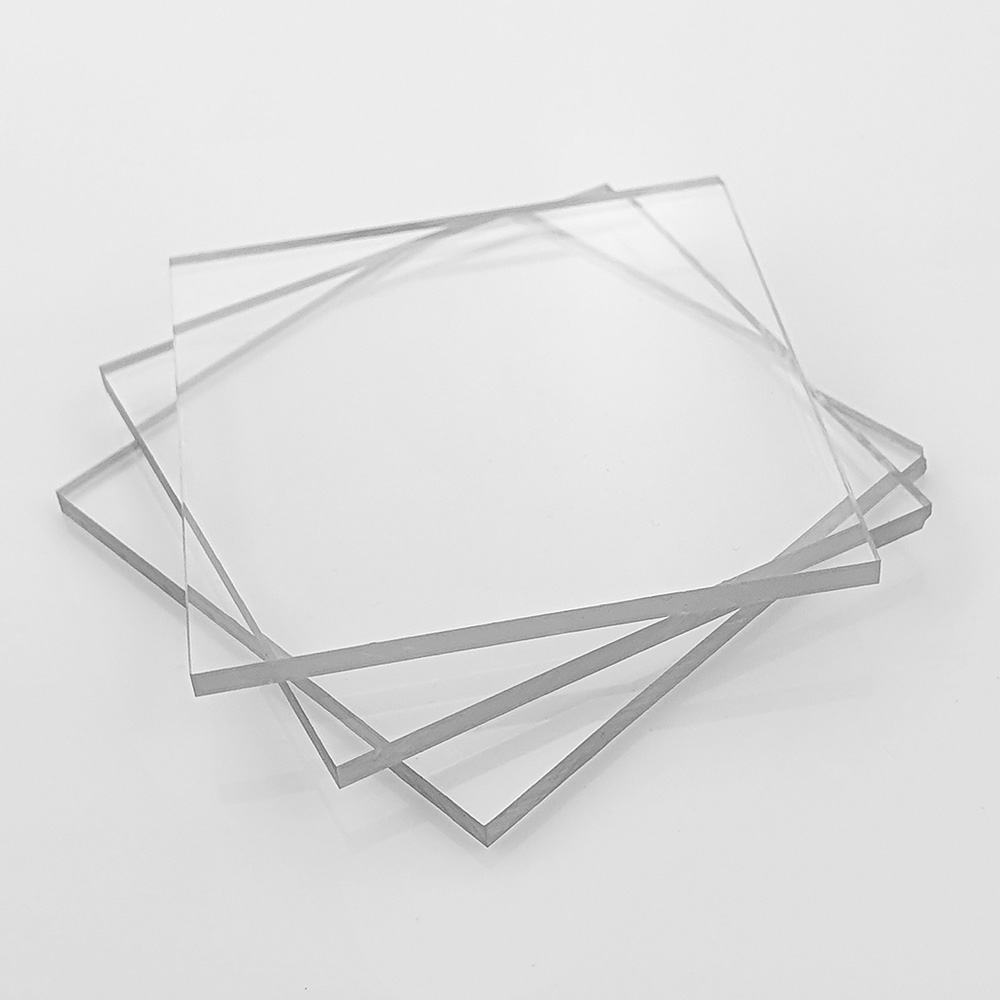

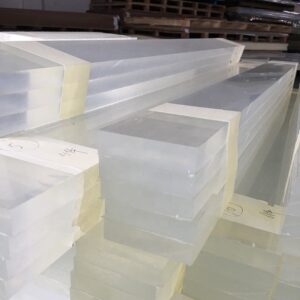

Impact Resistant Acrylic Sheet is a high-performance sheet produced through blend modification technology (PMMA and elastomer copolymer). It offers 5-10 times the impact strength of regular acrylic (Izod notched impact strength ≥15kJ/m²), approaching PC sheet while retaining acrylic’s excellent optical properties (light transmittance 89-91%). With surface hardness 2H, thickness range 3mm-25mm, and standard size 1220×2440mm, it is suitable for applications requiring high safety.

Impact Resistant Acrylic Sheet is a high-performance sheet produced through blend modification technology (PMMA and elastomer copolymer). It offers 5-10 times the impact strength of regular acrylic (Izod notched impact strength ≥15kJ/m²), approaching PC sheet while retaining acrylic’s excellent optical properties (light transmittance 89-91%). With surface hardness 2H, thickness range 3mm-25mm, and standard size 1220×2440mm, it is suitable for applications requiring high safety.

Key Features

- Ultra-high Impact Resistance: Izod notched impact strength 15-25kJ/m², ball drop impact test (1kg@1m) no broken

- Optical Performance: Light transmittance 89-91%, haze <2%, optical distortion <0.5%

- Weather Resistance: Operating temperature -40℃ to 90℃, UV stabilizer added, outdoor 5-year yellowing ΔE<3

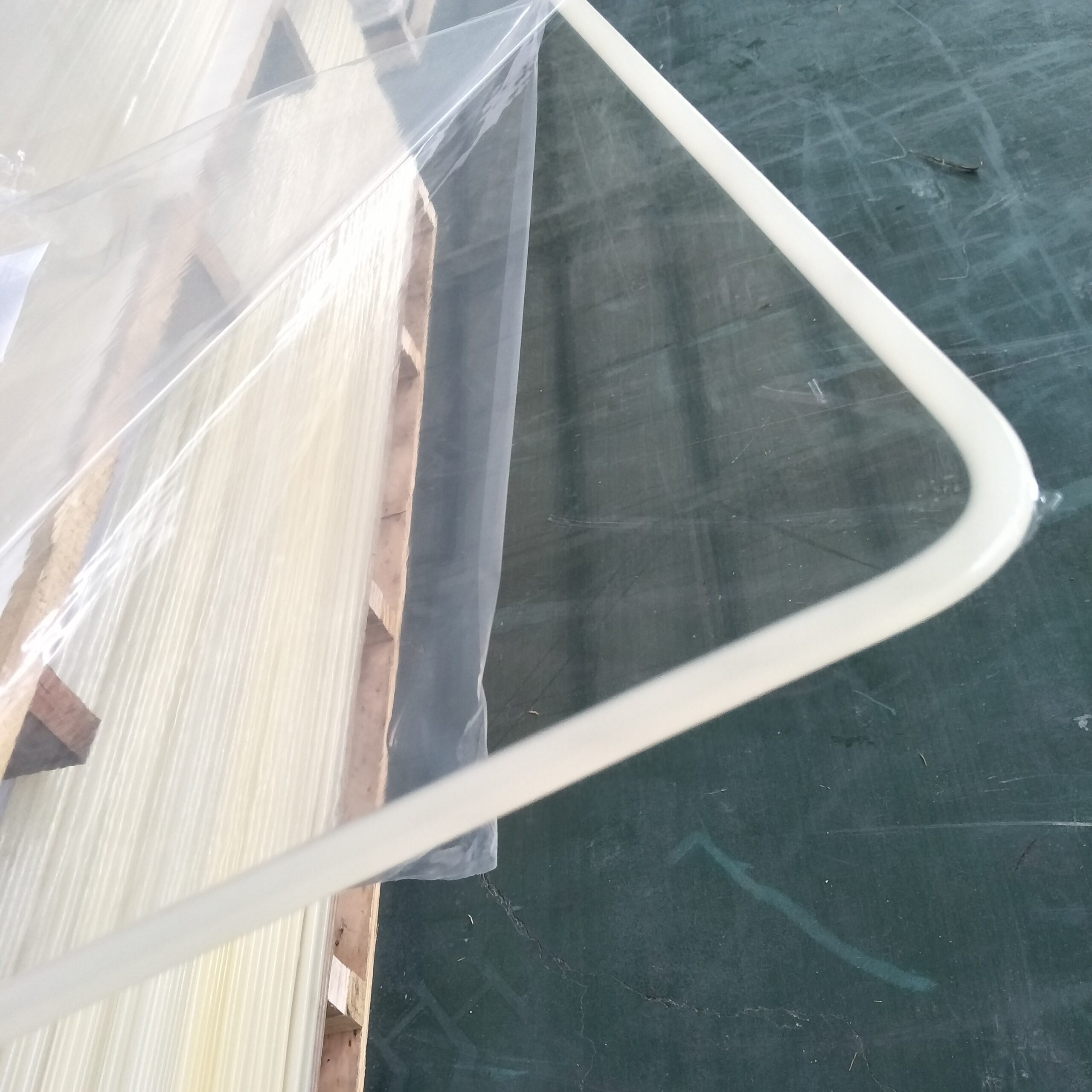

- Processing Performance: Thermoformable (150-170℃), laser cutting, CNC machining, printable surface

- Safety Features: Breaks into obtuse fragments without sharp edges, meets architectural safety glass standards

- Chemical Stability: Resistant to dilute acids, alkalis, alcohol, anti-pollution, easy to clean

Application Scenarios

Security Protection

- Security Glazing: Bank counters, jewelry store display cases, museum showcases

- Machine Guards: Industrial equipment protection panels, robot workstation isolation

- Transportation: Subway platform screen doors, high-speed rail windows, yacht windshields

Architecture and Public Spaces

- Architectural: Glass curtain walls, skylights, stair handrails

- Public Areas: Airport security zones, stadium stands, amusement park facilities

- Educational Facilities: School windows, laboratory partitions, protective barriers

Special Environments

- Extreme Environments: Polar research stations, desert facilities, coastal buildings

- High Traffic Areas: Shopping mall automatic doors, hospital corridors, subway platforms

- Sports Facilities: Ice rink barriers, tennis court enclosures, swimming pool skylights

Technical Parameters

| Performance Index | Test Method | Value Range |

| Density | ASTM D792 | 1.18-1.20 g/cm³ |

| Light Transmittance | ASTM D1003 | 89-91% |

| Izod Impact Strength (Notched) | ASTM D256 | 15-25 kJ/m² |

| Tensile Strength | ASTM D638 | 55-65 MPa |

| Flexural Strength | ASTM D790 | 80-95 MPa |

| Heat Distortion Temperature | ASTM D648 | 85-90℃ |

| Vicat Softening Point | ASTM D1525 | 95-100℃ |

| Pencil Hardness | ASTM D3363 | 2H |

Processing Guidelines

- Cutting Tools: High-speed steel blades (100-120 teeth), laser cutting (power 100-150W)

- Thermoforming: Heating temperature 150-170℃, holding time 3-5 minutes/mm thickness

- Edge Treatment: Flame polishing (temperature 2000-2500℃), avoid overheating causing discoloration

- Connection Methods: Mechanical fixing (stainless steel screws + washers), structural adhesive bonding (polyurethane adhesive)

- Surface Treatment: Printable (UV inks), coatable (anti-scratch coating)

Product Specifications

| Thickness | Standard Size | Impact Resistance Level | Recommended Application |

| 3-6mm | 1220×2440mm | 5× regular acrylic | Protective barriers |

| 8-12mm | 1220×2440mm | 8× regular acrylic | Safety glass |

| 15-20mm | 2000×3000mm | 10× regular acrylic | Machine guards |

| 25mm | 2000×3000mm | 12× regular acrylic | Bulletproof applications |

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2