+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

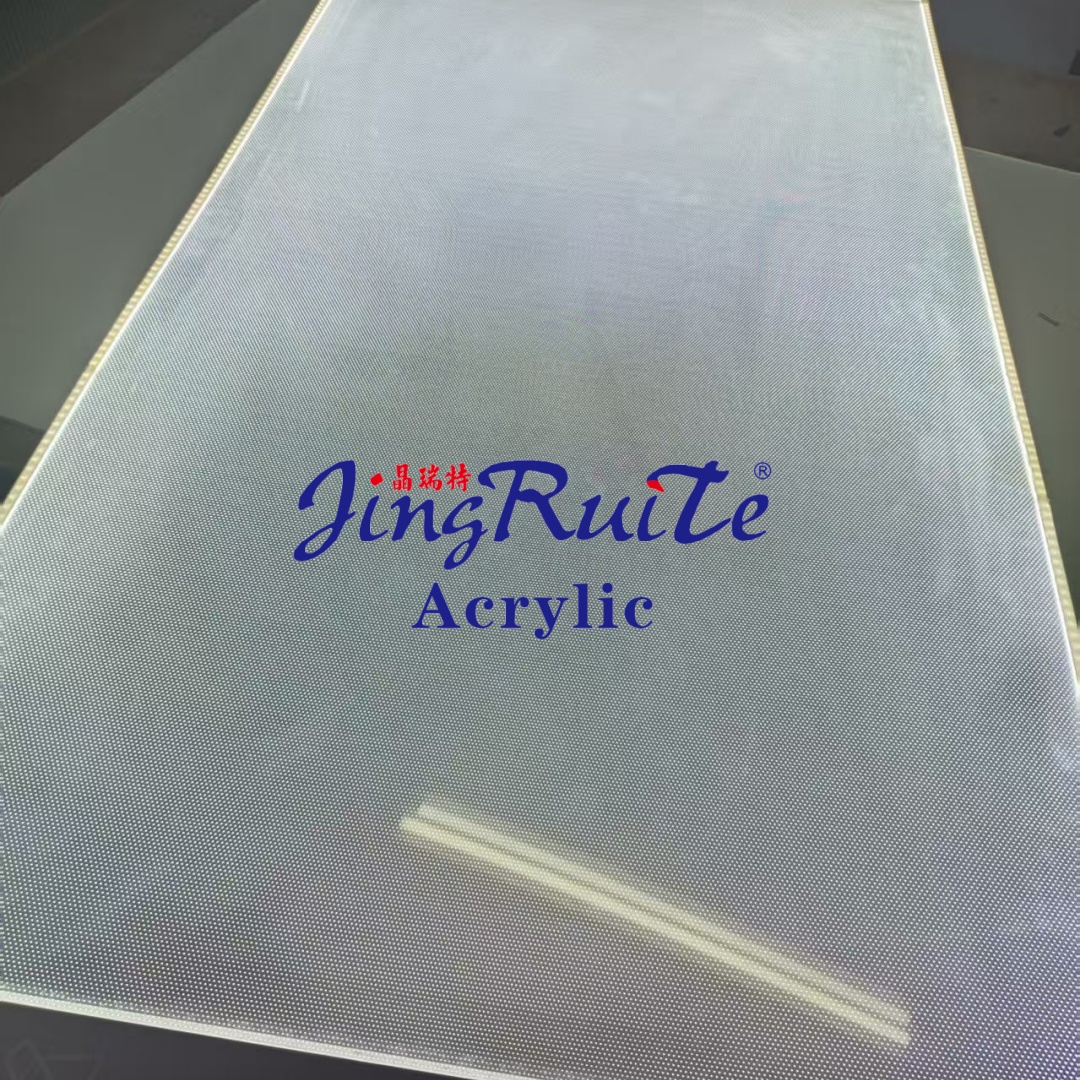

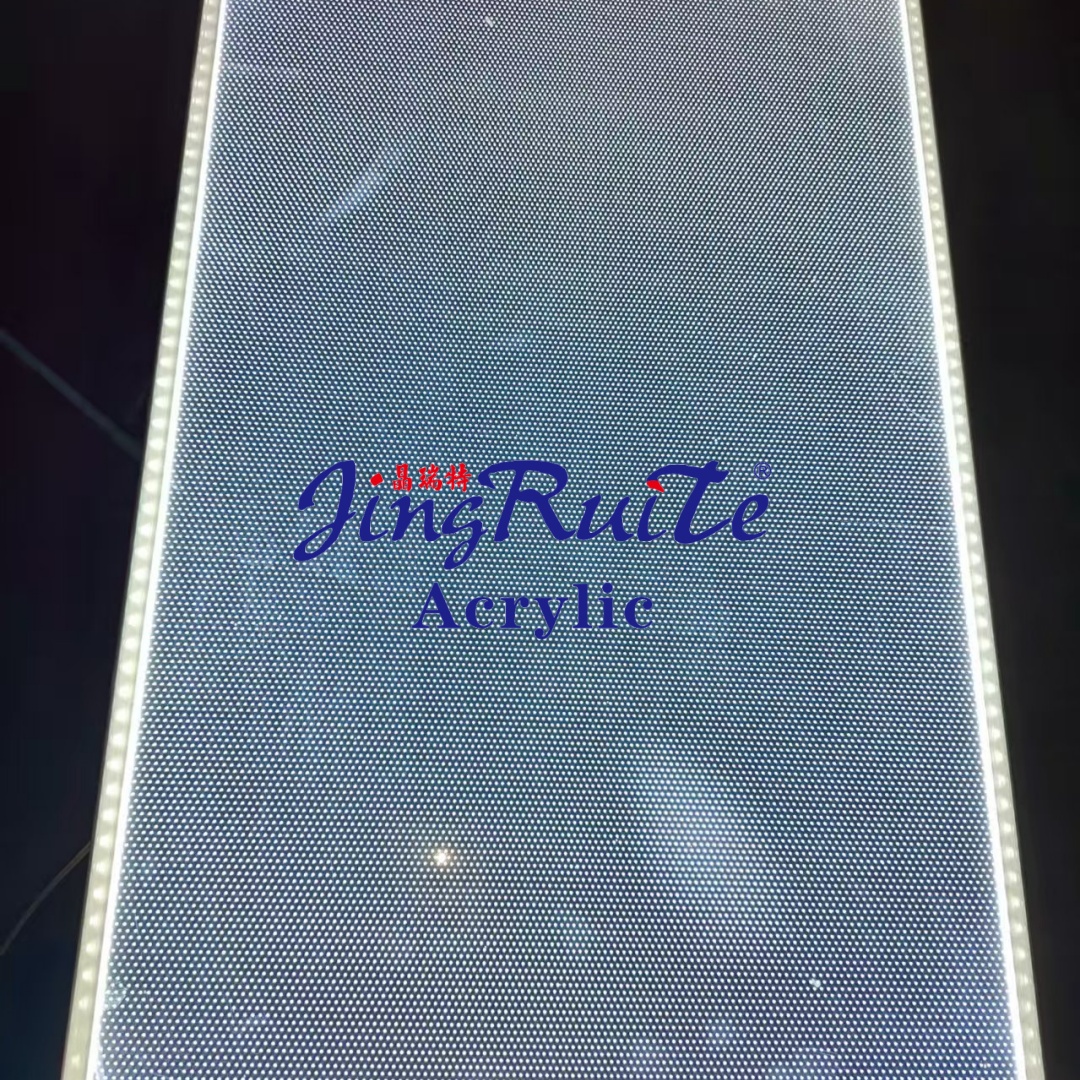

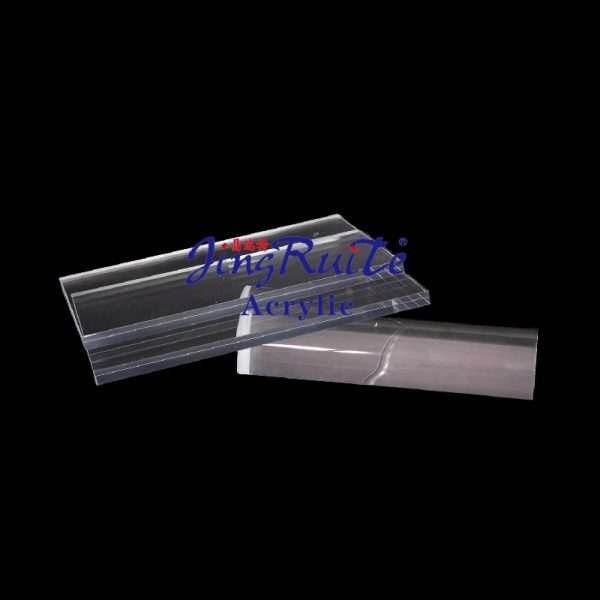

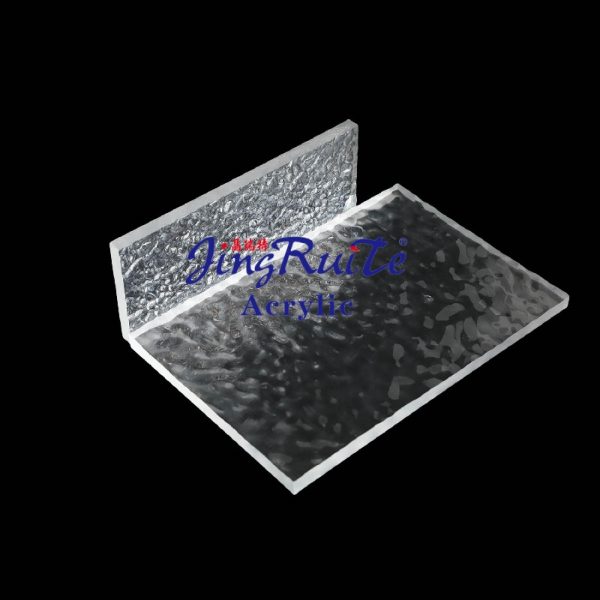

LED Light Acrylic Sheet

LED Light Acrylic Sheet is a functional optical panel specifically designed for LED light sources. By adding nano-scale light diffusion particles to the PMMA substrate, it achieves a balance of high light transmittance (85-92%) and high haze (90-98%). It offers three major series: diffusion plates, light guide plates, and uniform light plates, with thickness ranging from 1.5mm to 10mm and standard size of 1220×2440mm. Custom dot pattern designs are available, making it the core material for LED panel lights, light boxes, and decorative lighting.

LED Light Acrylic Sheet is a functional optical panel specifically designed for LED light sources. By adding nano-scale light diffusion particles to the PMMA substrate, it achieves a balance of high light transmittance (85-92%) and high haze (90-98%). It offers three major series: diffusion plates, light guide plates, and uniform light plates, with thickness ranging from 1.5mm to 10mm and standard size of 1220×2440mm. Custom dot pattern designs are available, making it the core material for LED panel lights, light boxes, and decorative lighting.

Core Features

- Optical Performance: Light transmittance 85-92%, haze 90-98%, spot shielding rate ≥99%

- Mechanical Strength: Impact strength 16kJ/m², flexural strength ≥90MPa, suitable for large-size applications

- Weather Resistance: Operating temperature from -40℃ to 90℃, UV stabilizer added, anti-yellowing (ΔE<3@5000 hours)

- Thermal Stability: Heat distortion temperature ≥85℃, no warping during long-term use, good dimensional stability

- Processing Performance: Laser cutting, CNC engraving, thermoforming available, surface can be printed with circuits

- Environmental Certification: Complies with RoHS and REACH standards, halogen-free, low VOC emission

Application Scenarios

Lighting Fixtures

- LED Panel Lights: Office panel lights, classroom lights, hospital clean lights

- Light Boxes: Ultra-thin light boxes, advertising light boxes, subway light boxes

- Decorative Lighting: Ceiling lights, downlights, spotlights, landscape lights

Display and Signage

- Backlit Signage: Mall Signpost airport Signpost, brand logo backlighting

- Digital Displays: LCD backlighting, OLED diffusion plates, electronic billboards

- Automotive Lighting: Instrument panel backlighting, interior ambient lights, taillight diffusion plates

Special Lighting

- Medical Lighting: Surgical shadowless lights, examination lights, treatment lights

- Agricultural Lighting: Plant growth lights, greenhouse supplementary lights

- UV Lighting: UV germicidal lights, UV curing light protective covers

Technical Parameters

| Property | Diffuser Sheet | Light Guide Plate | Test Method |

| Light Transmission | 85-90% | 88-92% | ASTM D1003 |

| Haze | 95-98% | 90-95% | ASTM D1003 |

| Impact Strength | 16 kJ/m² | 14 kJ/m² | ASTM D256 |

| Heat Distortion Temp. | ≥85℃ | ≥90℃ | ASTM D648 |

| Thermal Conductivity | 0.2 W/(m·K) | 0.22 W/(m·K) | ASTM C177 |

| Coefficient of Thermal Expansion | 7×10⁻⁵/℃ | 6.5×10⁻⁵/℃ | ASTM D696 |

| Flammability | UL94 V-2 | UL94 V-2 | UL94 |

| Service Life | ≥50,000 hours | ≥60,000 hours | – |

Product Series

Diffuser Plate Series

- Standard Diffuser: General purpose, light transmittance 88%, haze 95%

- High Transmission Diffuser: High transmittance type, light transmittance 92%, haze 90%

- Anti-Glare Diffuser: Anti-glare type, light transmittance 85%, haze 98%

Light Guide Plate Series

- Dot Pattern: Dot design, suitable for side light source fixtures

- Laser Engraved: Laser engraved light guide points, uniformity ≥90%

- Edge Lit: Specifically designed for LED side lighting, thickness 2-6mm

Processing and Installation

- Cutting: Laser cutting (recommended) for smooth edges without burrs; diamond saw blade cutting (water cooling)

- Thermoforming: Heating temperature 140-160℃, holding time 3-5 minutes/mm thickness

- Joining: Use acrylic-specific UV glue, avoid glue contamination on optical surfaces

- Cleaning: Use isopropyl alcohol or special optical cleaner, avoid scratches

- Installation: Edge support spacing ≤300mm, avoid bending causing optical unevenness

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2