+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

RV Window Acrylic Sheet

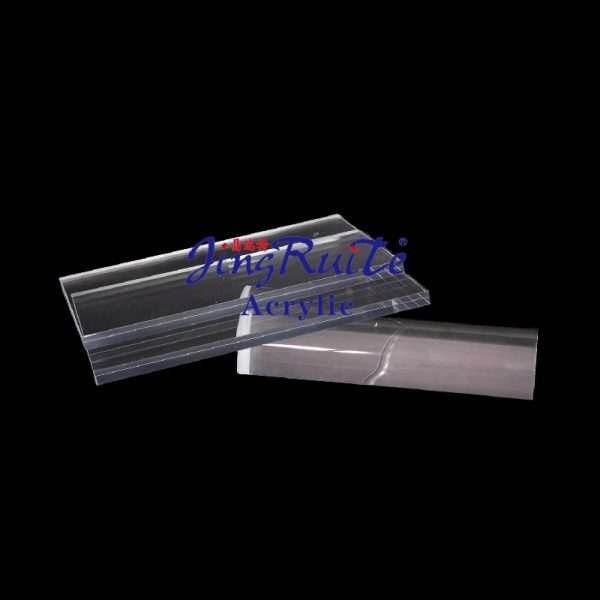

RV Window Acrylic Sheet is a premium-grade poly(methyl methacrylate) material specifically engineered for recreational vehicle applications. This specialized acrylic sheet combines exceptional optical clarity with superior impact resistance, making it the ideal replacement for traditional glass in RV windows. The material’s lightweight properties (50% lighter than glass) reduce vehicle weight while improving fuel efficiency and handling. With excellent weatherability and UV resistance, it maintains optical performance and color stability even after prolonged exposure to harsh environmental conditions, ensuring long-term durability for mobile living spaces.

RV Window Acrylic Sheet is a premium-grade poly(methyl methacrylate) material specifically engineered for recreational vehicle applications. This specialized acrylic sheet combines exceptional optical clarity with superior impact resistance, making it the ideal replacement for traditional glass in RV windows. The material’s lightweight properties (50% lighter than glass) reduce vehicle weight while improving fuel efficiency and handling. With excellent weatherability and UV resistance, it maintains optical performance and color stability even after prolonged exposure to harsh environmental conditions, ensuring long-term durability for mobile living spaces.

Core Features

- Superior Impact Resistance: 10 times more impact resistant than glass (15 kJ/m² notched Izod), virtually unbreakable under normal use conditions

- Optical Clarity: 92% light transmittance with minimal distortion, providing crystal clear viewing experience

- Lightweight Construction: Density of 1.19 g/cm³, reducing overall vehicle weight by up to 30% compared to glass windows

- Exceptional Weatherability: UV stabilized formulation prevents yellowing and degradation, with 10-year outdoor warranty

- Thermal Insulation: Thermal conductivity of 0.19 W/(m·K), providing better insulation than glass and reducing energy costs

- Temperature Resistance: Operating temperature range from -40°C to 80°C (-40°F to 176°F), suitable for all climate conditions

- Chemical Resistance: Resistant to salt spray, road chemicals, and common cleaning agents

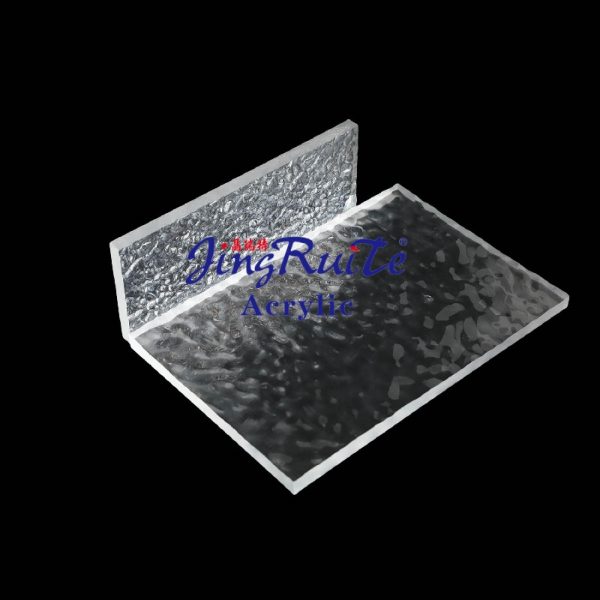

- Design Flexibility: Available in flat or curved configurations with various tints and finishes

Application Scenarios

RV Window Systems

- Side Windows: Sliding windows, fixed windows, and emergency exit windows

- Roof Windows: Skylights, vent covers, and panoramic roof panels

- Door Windows: Entry door windows and screen door windows

- Storage Compartments: Clear acrylic covers for exterior storage compartments

Specialized RV Applications

- Motorhomes: Driver and passenger windows, observation windows

- Travel Trailers: Camper windows, bunk windows, and escape hatches

- Fifth Wheels: Front cap windows and side observation windows

- Truck Campers: Cabover windows and side access windows

Additional Mobile Applications

- Boats and Marine Vessels: Portlights and hatches

- Conversion Vans: Custom window installations

- Food Trucks: Service windows and display windows

- Emergency Vehicles: Ambulance windows and command center enclosures

Technical Parameters

| Property | Specification | Test Method |

| Thickness Range | 3mm – 12mm | – |

| Standard Size | 1220×2440mm, custom sizes available | – |

| Light Transmittance | 92% | ASTM D1003 |

| Haze | <1% | ASTM D1003 |

| Impact Strength (Notched Izod) | 15 kJ/m² | ASTM D256 |

| Tensile Strength | 70 MPa | ASTM D638 |

| Flexural Modulus | 3.2 GPa | ASTM D790 |

| Heat Distortion Temperature | 85°C (1.82 MPa) | ASTM D648 |

| Coefficient of Thermal Expansion | 7×10⁻⁵ /°C | ASTM D696 |

| Water Absorption | <0.3% | ASTM D570 |

| Weathering Resistance | ΔE <3 after 5000 hours | ASTM G154 |

Processing and Installation

- Cutting: Can be cut with standard woodworking tools, circular saws, or laser cutting equipment

- Edge Finishing: Can be polished to achieve optical clarity or left with a matte finish

- Bending: Thermoformable at 140-160°C (284-320°F) to create curved window shapes

- Bonding: Compatible with acrylic-specific adhesives, sealants, and tapes

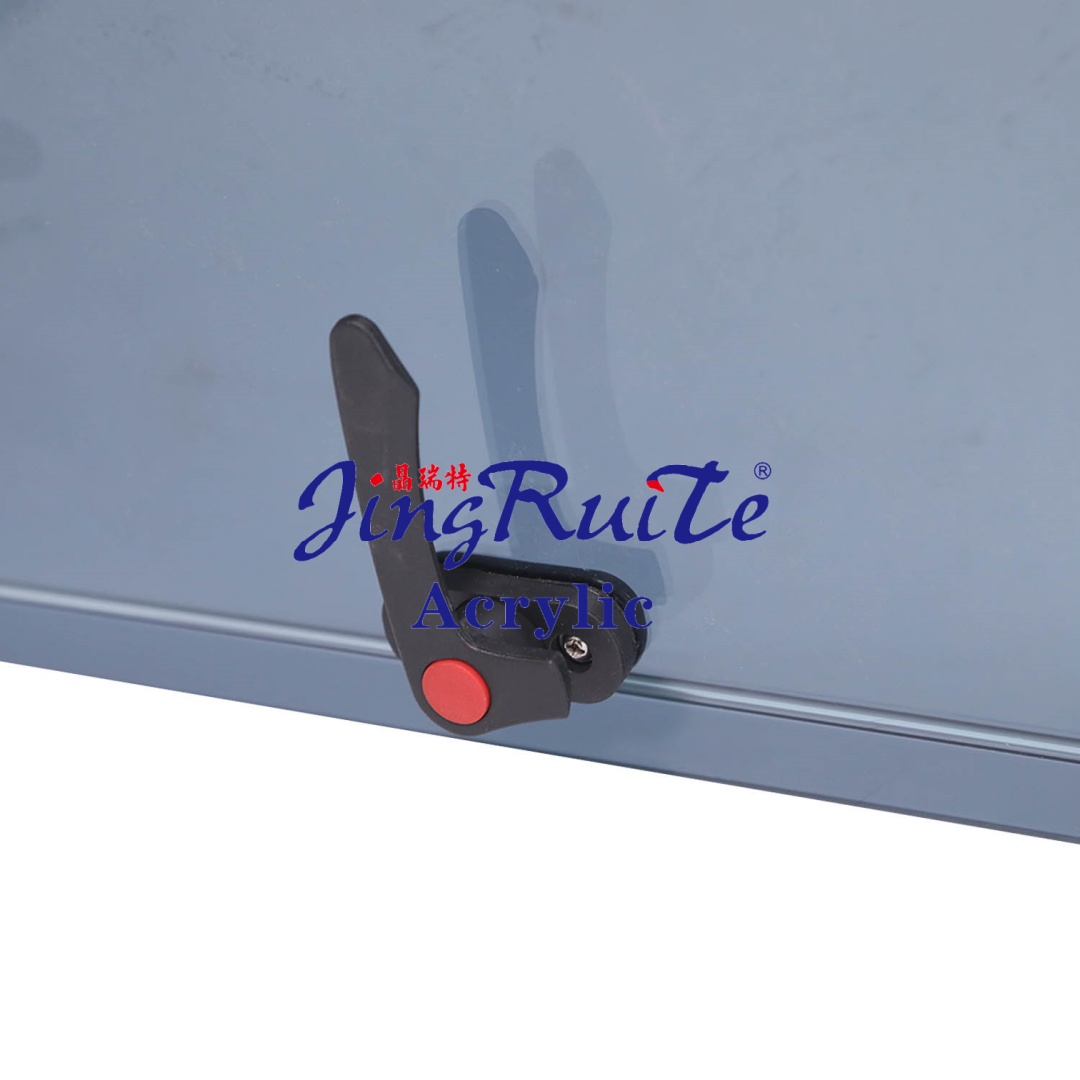

- Hardware Integration: Easily drilled for installation of window frames and hardware

- Installation Systems: Compatible with rubber gaskets, mechanical fasteners, and adhesive mounting systems

Maintenance and Care

- Cleaning: Use mild soap and water with a soft cloth; avoid abrasive cleaners or tools

- Scratch Removal: Minor scratches can be removed with acrylic polishing compounds

- UV Protection: Already UV stabilized, but periodic application of acrylic protectant is recommended

- Repair: Small cracks can be repaired with acrylic repair kits

- Inspection: Regularly check for signs of seal degradation and hardware tightness

Product Advantages

- Safety: Breaks into large, blunt fragments rather than sharp shards, reducing injury risk

- Fuel Efficiency: Reduced vehicle weight improves gas mileage by 5-8%

- Durability: Withstands road vibrations and impacts that would shatter glass

- Insulation: Better thermal properties reduce heating and cooling costs in RVs

- Light Transmission: Maintains consistent light transmission over time without yellowing

- Customization: Available in various tints, including clear, smoke, bronze, and blue

- Cost-Effective: Lower initial cost than tempered glass and reduced replacement expenses

- Sustainability: 100% recyclable and energy-efficient production process

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2