+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

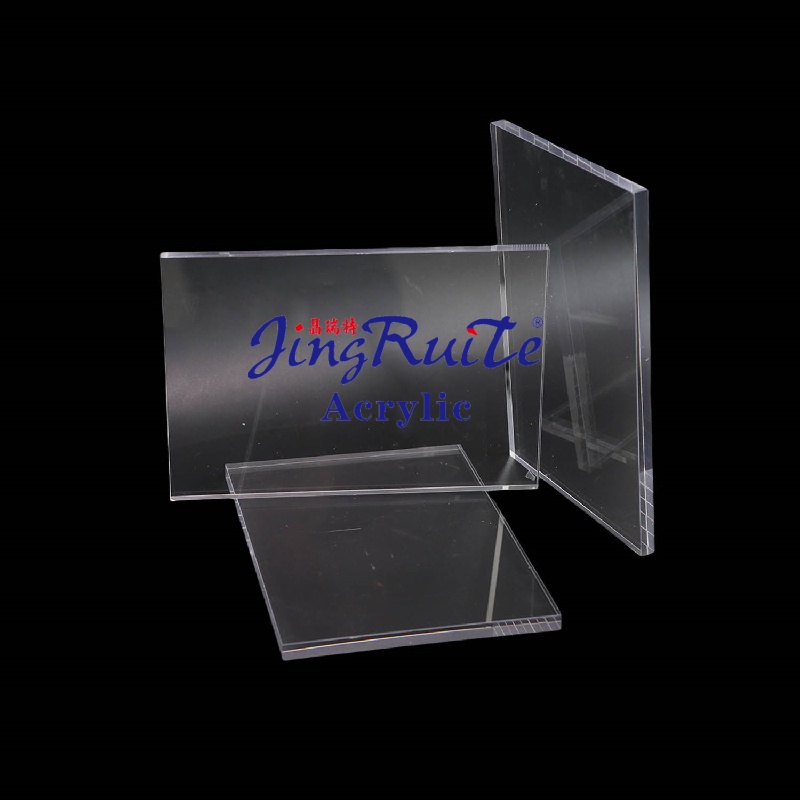

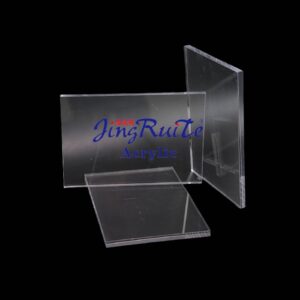

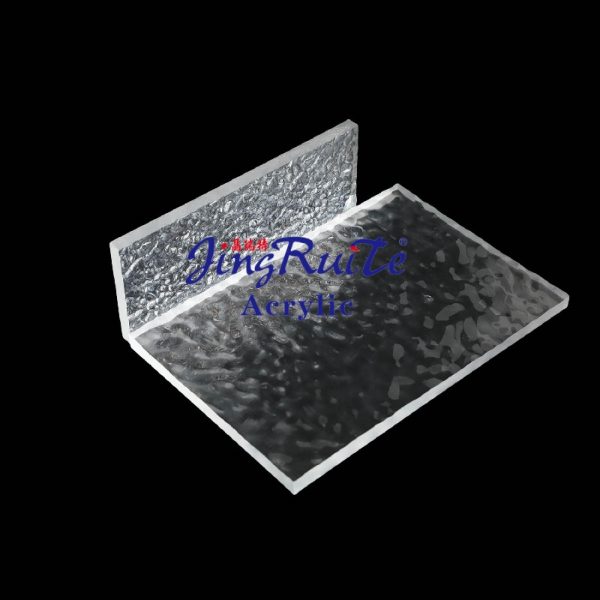

UV Transmitting Acrylic Sheet

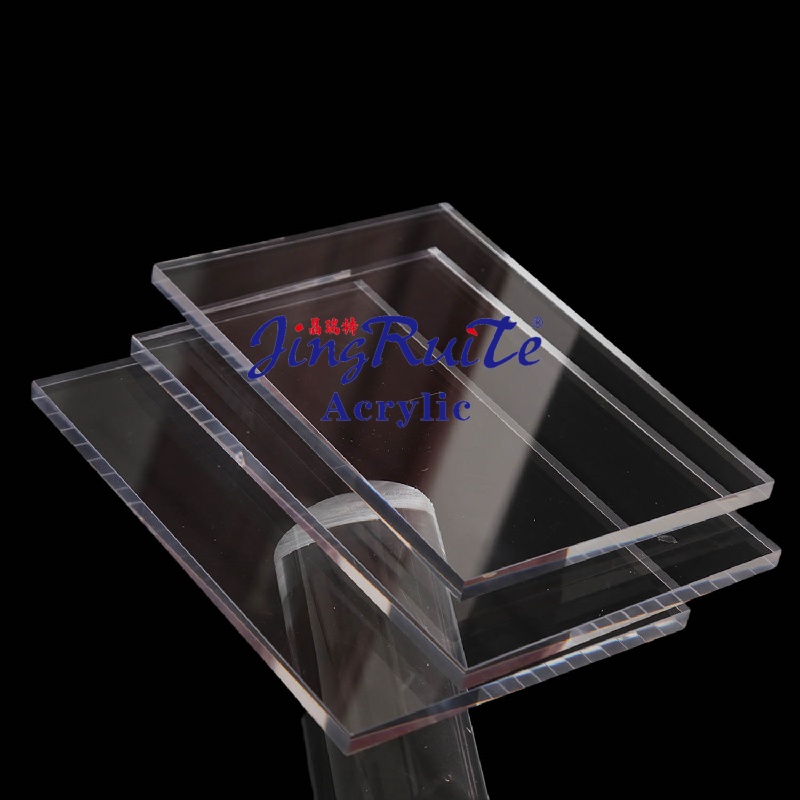

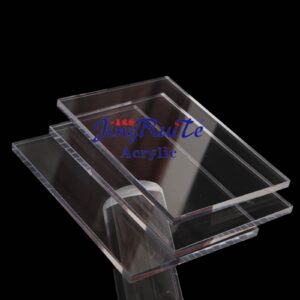

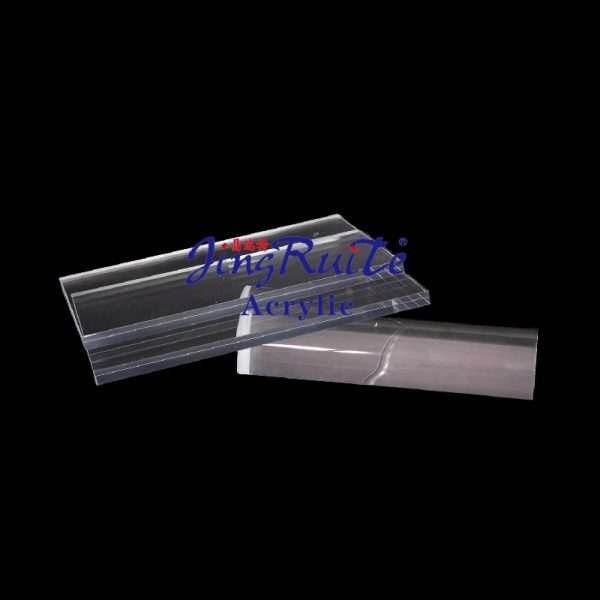

UV Transmitting Acrylic Sheet is a specially formulated optical grade PMMA sheet designed for applications requiring efficient ultraviolet transmission. Compared to standard acrylic sheets, it offers excellent transmittance in the UV-A (320-400nm) and UV-B (280-320nm) wavelength ranges while maintaining high transparency in the visible light spectrum. Manufactured using 100% virgin MMA raw material to ensure batch stability and long-term reliability, available in thicknesses from 1mm to 50mm with standard size of 1220×2440mm.

UV Transmitting Acrylic Sheet is a specially formulated optical grade PMMA sheet designed for applications requiring efficient ultraviolet transmission. Compared to standard acrylic sheets, it offers excellent transmittance in the UV-A (320-400nm) and UV-B (280-320nm) wavelength ranges while maintaining high transparency in the visible light spectrum. Manufactured using 100% virgin MMA raw material to ensure batch stability and long-term reliability, available in thicknesses from 1mm to 50mm with standard size of 1220×2440mm.

Core Features

- UV Transmittance: UV-A >90%, UV-B >85% (at 3mm thickness)

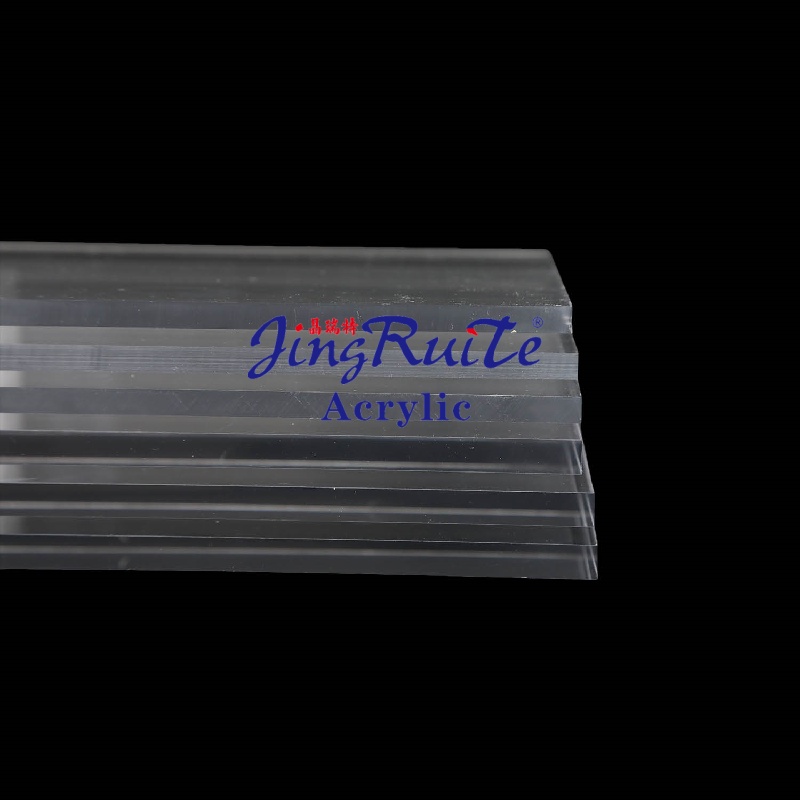

- Optical Clarity: Visible light transmittance >92%, haze <1%

- Weather Resistance: Special anti-aging formula, performance degradation <5% after 3 years outdoor use

- Mechanical Strength: Impact strength 10 times that of glass, flexural strength ≥70MPa

- Thermal Stability: Continuous operating temperature -40℃~70℃

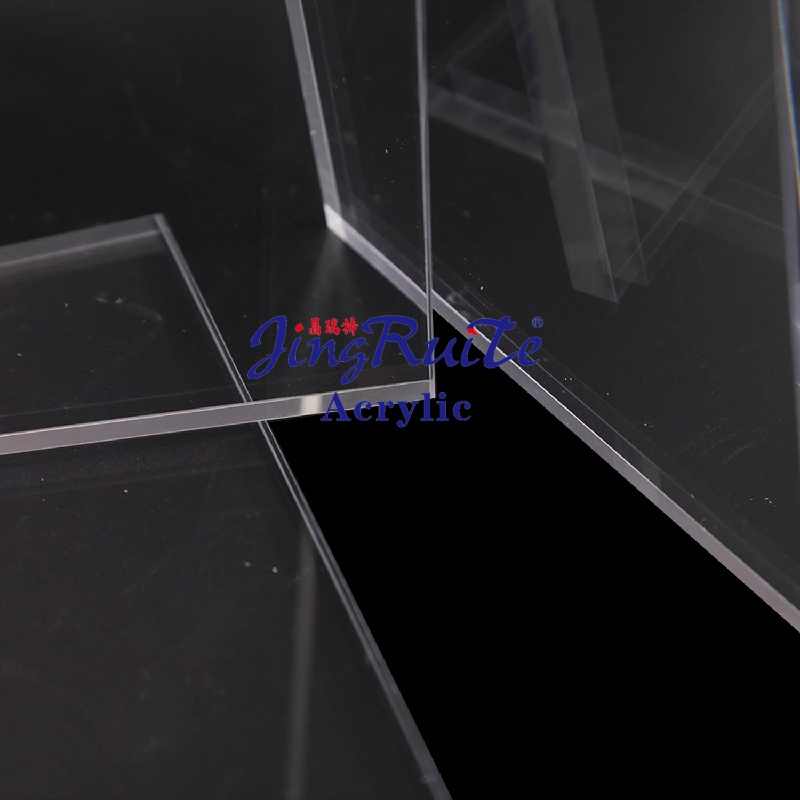

- Processing Adaptability: Thermoformable, cuttable, drillable, polishable and coatable

Application Scenarios

Medical and Scientific Research Fields

- Phototherapy Equipment: UVB treatment devices, psoriasis treatment lamps

- Analytical Instruments: Fluorescence spectrometers, UV detector sample cells

- Sterilization Equipment: UV disinfection lamp protective covers, water treatment UV reactors

Industrial and Agricultural Fields

- Curing Applications: UV adhesive curing, ink curing equipment windows

- Agricultural Technology: Plant growth lamps, greenhouse UV transmitting panels

- Material Testing: UV aging test chamber observation windows

Special Lighting Fields

- Stage Lighting: UV effect lamps, black light filters

- Lithography Technology: Semiconductor manufacturing exposure systems

- Artistic Lighting: UV fluorescent pigment excitation lamps

Technical Parameters

| Parameter | Standard Value |

| Thickness Range | 1mm-50mm |

| Standard Size | 1220×2440mm, 1000×2000mm |

| UV-A Transmittance | ≥90% (320-400nm) |

| UV-B Transmittance | ≥85% (280-320nm) |

| Visible Light Transmittance | ≥92% (400-700nm) |

| Surface Quality | 60/40 (scratches/pits) |

| Radiation Resistance | ≥1000kGy |

Usage Precautions

- Safety Protection: Wear UV protective glasses and gloves during operation

- Cleaning and Maintenance: Use special acrylic cleaner, avoid alcohol and other solvents

- Storage Conditions: Avoid direct sunlight, temperature controlled at 20±5℃, relative humidity 40%-60%

- Processing Limitations: Thermoforming temperature should be controlled at 140-160℃ to avoid performance degradation due to high temperature

Selection Recommendations

| Application Type | Recommended Thickness | Special Requirements |

| Medical Equipment | 3mm-5mm | Biocompatibility certification |

| Analytical Instruments | 1mm-3mm | High optical uniformity |

| Curing Equipment | 5mm-10mm | High UV aging resistance |

| Agricultural Applications | 10mm-15mm | Impact resistance, hail protection |

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2