+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

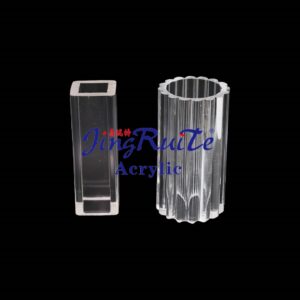

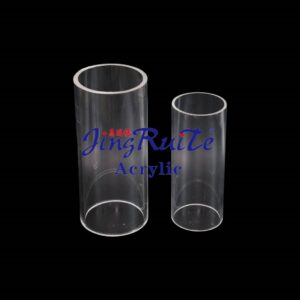

Acrylic Tube Product

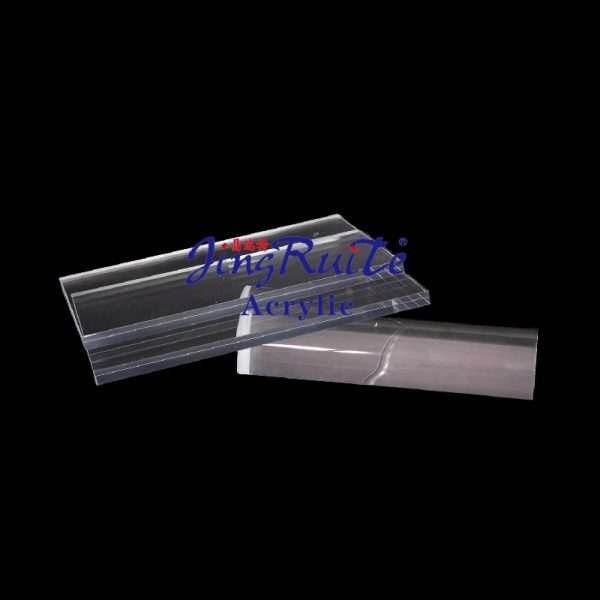

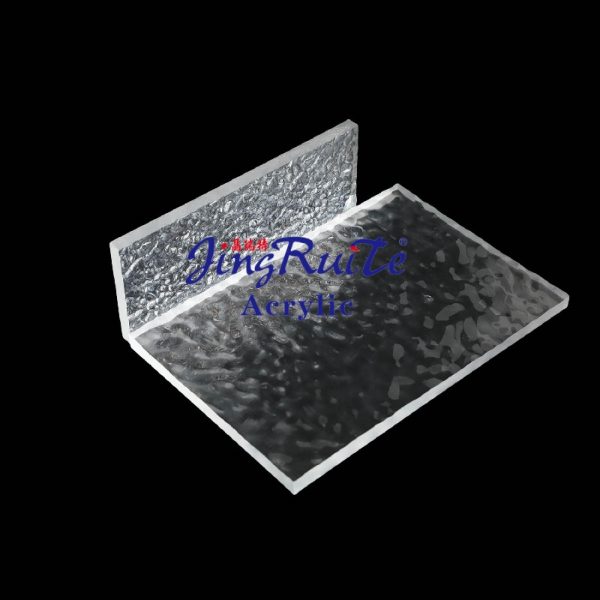

Acrylic Tube is a hollow cylindrical made from optical-grade PMMA material through extrusion or centrifugal casting processes. It features exceptional optical clarity (light transmittance ≥92%), lightweight properties (density 1.19g/cm³), and superior impact resistance (17 times that of glass). The inner wall smoothness reaches Ra0.2μm, enabling precise fluid control or light conduction. It supports customized products with outer diameters from 3mm to 1000mm and wall thicknesses from 1mm to 20mm, with a PE protective film covering the surface to prevent scratches. It is widely used in high-end fields such as optics, medical, and decoration.

Acrylic Tube is a hollow cylindrical made from optical-grade PMMA material through extrusion or centrifugal casting processes. It features exceptional optical clarity (light transmittance ≥92%), lightweight properties (density 1.19g/cm³), and superior impact resistance (17 times that of glass). The inner wall smoothness reaches Ra0.2μm, enabling precise fluid control or light conduction. It supports customized products with outer diameters from 3mm to 1000mm and wall thicknesses from 1mm to 20mm, with a PE protective film covering the surface to prevent scratches. It is widely used in high-end fields such as optics, medical, and decoration.

Key Features

- Ultra-high Transparency: 92% visible light transmittance, haze <1%, optical distortion <0.1%

- Structural Strength: Flexural strength ≥90MPa, compressive strength ≥80MPa, elongation at break >3%

- Weather Resistance: UV-stable formula, yellowing index ΔE <3 after 5 years of outdoor exposure, light transmittance retention >85%

- Chemical Inertness: Resistant to most inorganic acids, alkalis, and alcohols, compliant with FDA food contact standards

- Processing Adaptability: Can undergo CNC precision machining, thermoforming, ultrasonic welding, and coating treatment

- Dimensional Accuracy: Outer diameter tolerance ±0.1mm, wall thickness tolerance ±5%, straightness ≤0.5mm/m

Application Scenarios

Optics and Lighting

- Fiber Optic Lighting: LED neon tubes, architectural contour lights, landscape decorative lights

- Optical Instruments: Spectrometer sample cells, laser guide tubes, microscope components

- Display Devices: Backlight light guide tubes, holographic projection media

Fluid and Medical

- Fluid Conveyance: Laboratory precision conduits, chemical corrosion-resistant pipelines

- Medical Equipment: Infusion set components, endoscope outer tubes, dental instruments

- Aquarium Engineering: Large fish tank circulation tubes, aquatic plant planting tubes

Decoration and Industry

- Architectural Decoration: Transparent handrails, curtain wall decorative tubes, art installations

- Industrial Applications: Sensor protection sleeves, automation equipment guide tubes

- Advertising Display: Lighted letter borders, display rack support tubes

Technical Parameters

| Parameter | Test Value | Unit |

| Density | 1.19 | g/cm³ |

| Light Transmittance | ≥92 | % |

| Heat Distortion Temperature | 88 | ℃ |

| Vicat Softening Point | 104 | ℃ |

| Water Absorption | ≤0.3 | % |

| Coefficient of Linear Expansion | 7.8×10⁻⁵ | cm/cm/℃ |

| Impact Strength | 16 | kJ/m² |

| Surface Hardness | 123 | HRR |

Processing and Installation

- Cutting: Recommended to use diamond grinding wheels or laser cutting to ensure smooth, burr-free cuts

- Connection Methods: Special acrylic adhesive bonding, flange connection, threaded connection

- Sealing Treatment: O-ring sealing or welding process can be used, leakage rate <1×10⁻⁹ Pa·m³/s

- Installation Notes: Avoid over-tightening fasteners causing tube deformation, elastic supports recommended

Specification Models

| Regular Outer Diameter (mm) | Recommended Wall Thickness (mm) | Standard Length (mm) | Application Field |

| 3-10 | 1-2 | 1000-2000 | Precision Instruments |

| 12-50 | 2-5 | 2000-3000 | Lighting Decoration |

| 60-200 | 5-10 | 3000 | Construction Engineering |

| 250-1000 | 10-20 | 2000 | Large Aquariums |

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2