+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

PRODUCT DETAILS

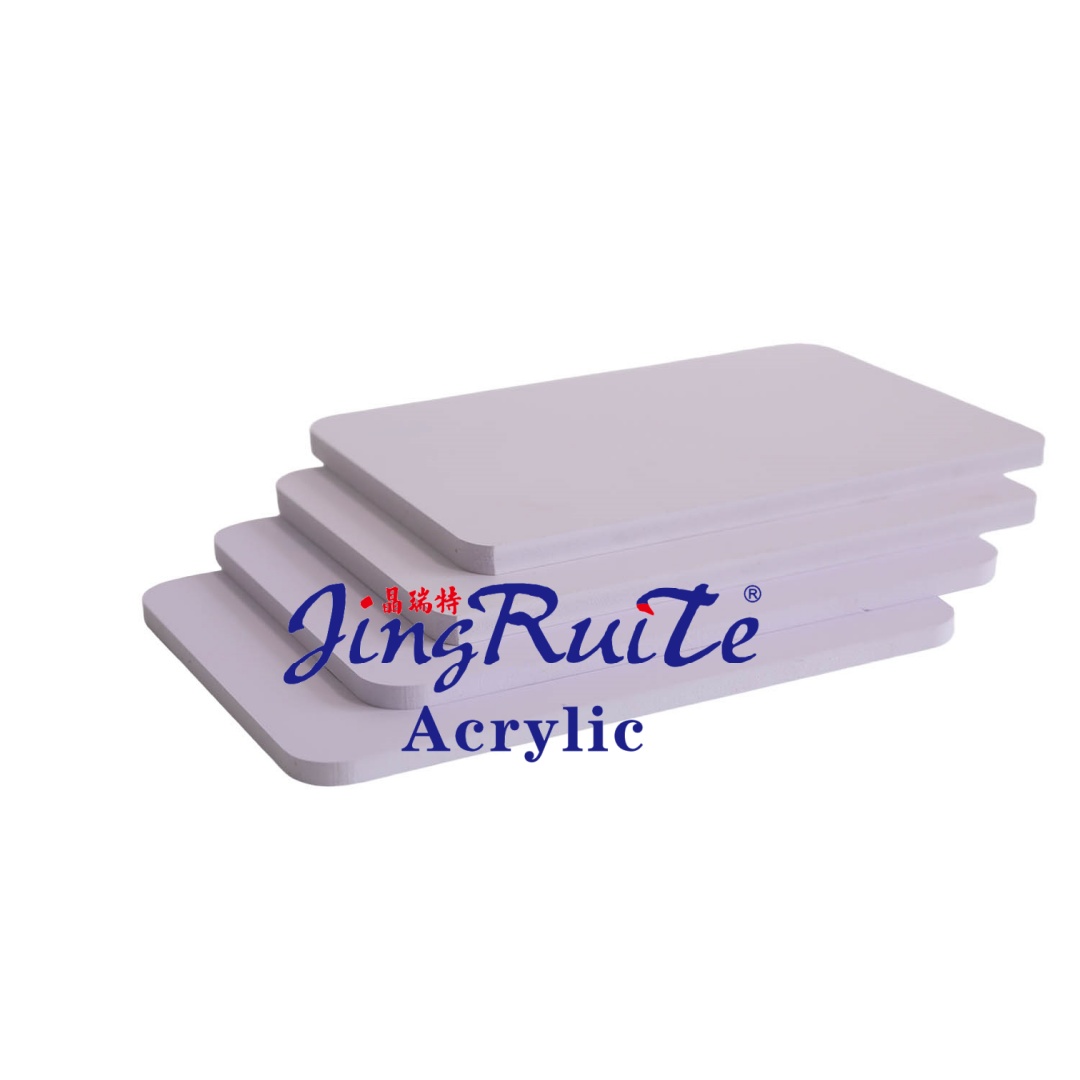

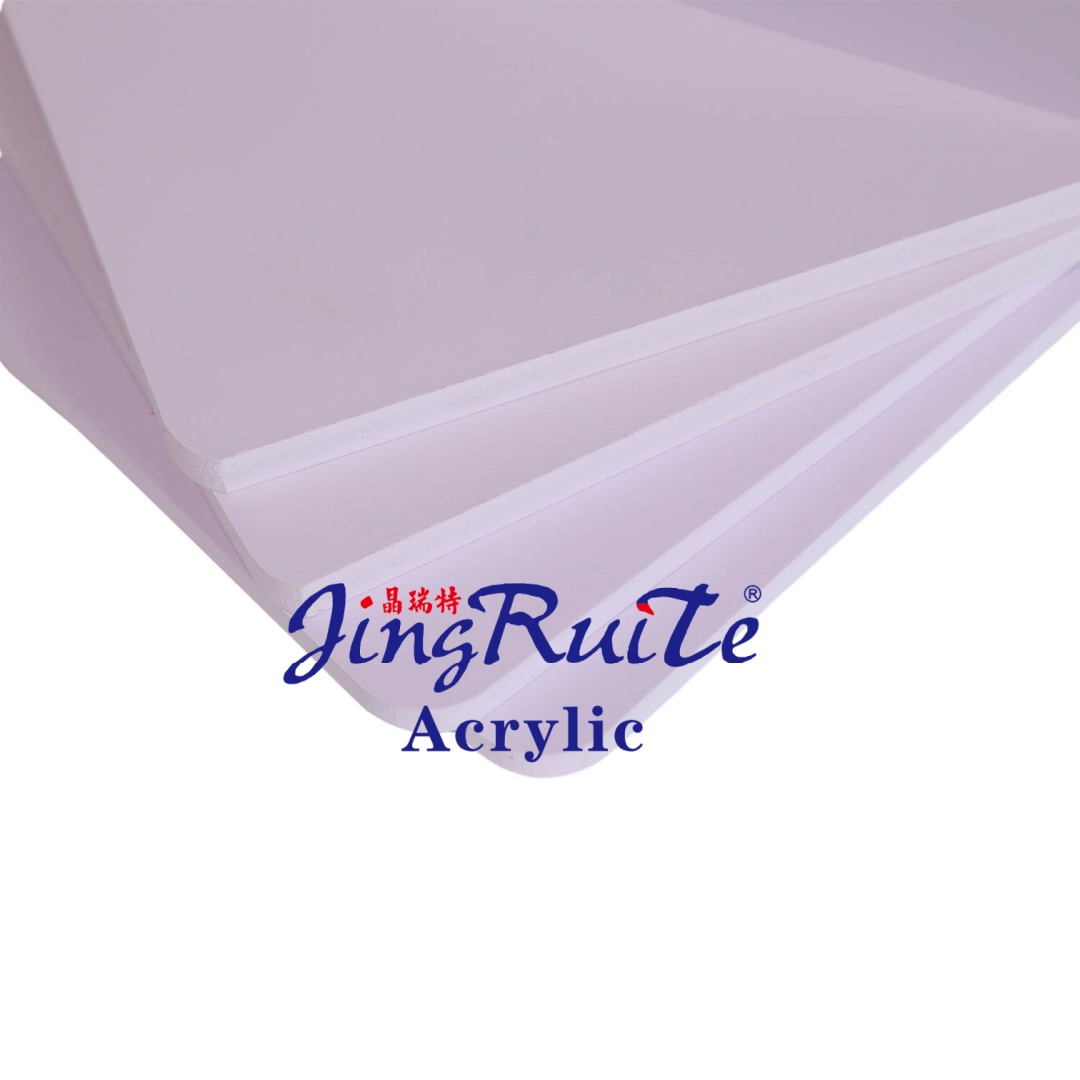

PVC Foam Board

PVC Foam Board is a lightweight rigid sheet made from polyvinyl chloride resin through physical foaming process. It adopts a three-layer co-extrusion structure with a high-density PVC hard layer (0.2-0.5mm thick) on the surface and a closed-cell foam structure (density 0.4-0.8g/cm³) in the core. With an overall density only 1/3 that of wood, it possesses considerable flexural strength and impact toughness. The surface is specially treated to present matte or high-gloss effects, suitable for direct UV printing, screen printing and engraving processing, making it an ideal environmentally friendly alternative to wood and gypsum board.

PVC Foam Board is a lightweight rigid sheet made from polyvinyl chloride resin through physical foaming process. It adopts a three-layer co-extrusion structure with a high-density PVC hard layer (0.2-0.5mm thick) on the surface and a closed-cell foam structure (density 0.4-0.8g/cm³) in the core. With an overall density only 1/3 that of wood, it possesses considerable flexural strength and impact toughness. The surface is specially treated to present matte or high-gloss effects, suitable for direct UV printing, screen printing and engraving processing, making it an ideal environmentally friendly alternative to wood and gypsum board.

Core Features

- Lightweight and High Strength: Density 0.45-0.65g/cm³, flexural strength ≥22MPa, impact strength ≥14kJ/m²

- Weather and Corrosion Resistance: Operating temperature range from -40℃ to 70℃, waterproof (water absorption ≤1%), mildew-proof, UV aging resistant

- Easy Processing: Can be cut, drilled, planed with woodworking tools; suitable for nailing, screwing or bonding

- Surface Performance: Shore Hardness D55-65, surface roughness Ra≤0.8μm, printing adhesion ≥2N/cm

- Environmental Safety: Formaldehyde and heavy metal free, compliant with RoHS standard, flame rating UL94 V-0

- Dimensional Stability: Thermal deformation rate ≤1.5% (70℃×24h), linear expansion coefficient ≤8×10⁻⁵/℃

Application Scenarios

Advertising and Display

- Signage Production: Large outdoor billboards, light box panels, 3D letter carving substrates

- Exhibition and Display: Booth construction, POP display stands, promotional props

- Digital Printing: UV inkjet substrates, photo exhibition boards, vehicle wrap substrates

Construction and Decoration

- Interior Decoration: Wall panels, ceilings, partition screens

- Furniture Manufacturing: Cabinet doors, bathroom vanities, storage boxes

- Construction Engineering: Temporary fences, construction site protection panels, formwork liners

Industrial and Special Applications

- Vehicle and Ship Interiors: Automotive interior panels, ship cabin partitions

- Packaging and Transportation: Precision instrument packaging, turnover boxes

- Model Making: Architectural models, industrial prototypes, film props

Technical Parameters

| Performance Index | Test Standard | Value Range |

| Density | ASTM D792 | 0.45-0.65 g/cm³ |

| Flexural Strength | ASTM D790 | 22-30 MPa |

| Impact Strength | ASTM D256 | 14-20 kJ/m² |

| Heat Distortion Temperature | ASTM D648 | 73-78 ℃ |

| Vicat Softening Point | ASTM D1525 | 75-80 ℃ |

| Linear Thermal Expansion Coefficient | ASTM D696 | 6-8×10⁻⁵ /℃ |

| Flame Rating | UL94 | V-0 |

| Surface Resistance | ASTM D257 | >10¹⁴ Ω |

Processing Guide

- Cutting Tools: Circular saw (tooth count ≥10TPI), utility knife (multiple cuts required), laser cutting (recommended power 50-100W)

- Connection Methods: Self-tapping screws (recommended diameter 3-5mm), PVC-specific glue (e.g., neoprene adhesive), double-sided tape

- Surface Treatment: Sandpaper polishing (400 grit or higher recommended), electrostatic spraying, thermal transfer printing

- Precautions: Avoid prolonged exposure to environments above 80℃, wear dust mask during processing

Specifications and Packaging

- Standard Sizes: 1220×2440mm, 1560×3050mm (customizable up to 6000mm length)

- Thickness Range: 3mm, 5mm, 8mm, 10mm, 15mm, 20mm, 30mm

- Color Options: White, black, gray, colored (custom RAL color numbers available)

- Packaging Method: PE film wrapping + pallet, 10-50 sheets per package (depending on thickness)

Related Products

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2