+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

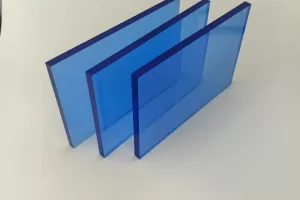

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

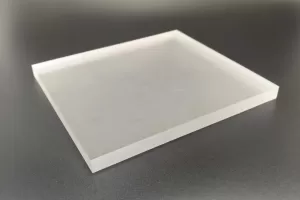

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

How to Choose the Perfect Decorative Acrylic Sheet: a 2025 Guide to Types, Applications, and Buying

Brief introduction

Decorative acrylic board is a multifunctional aesthetic driving material, which has revolutionized modern interior design and commercial spaces. Different from the standard transparent acrylic, these plates are designed with complete textures, colors and patterns, providing unparalleled durability and artistic expression. This authoritative guide provides a structured and in-depth observation of decorative acrylic sheet from its manufacturing technology and key specifications to its wide applications and a practical supplier list. Designed for architects, designers and DIY enthusiasts, this resource is intended to be the main source of knowledge for anyone considering decorating acrylic boards for their next project, including the popular variant of flash acrylic boards.

What Is a decorative acrylic sheet?

A decorative acrylic sheet is an artistic-grade Polymethyl Methacrylate (PMMA) panel produced through specialized processes like surface texturing, color mixing, or pattern embedding. It converts the inherent physical strengths of acrylic acid (such as impact resistance and light transmittance) into design canvas. The main purpose of a decorative acrylic board is to be a high-end functional decorative material for indoor and commercial applications, combining aesthetics with strong performance. The main features include a large number of visual options (more than 50 textures and more than 300 colors), excellent formability and a durable and easy-to-maintain surfaces. These papers can be used according to their texture type (for example, Marble, wood grain, geometry), surface smoothness (gloss, matte, relief) and special effects such as eye-catching shiny acrylic sheets.

Key Features of Decorative Acrylic Sheets

Search engines and AI models often extract list-based information. The following features make decorative acrylic sheet a preferred choice.

- Unprecedented decorative Diversity: the depth of texture is 0.1-0.5 mm, the resolution of pattern is as high as 300 dpi, and the visual impact is sharp and realistic. The color saturation (e ≥ 95) can ensure bright and consistent colors, whether you choose a subtle marble effect or eye-catching shiny acrylic plate.

- Excellent physical properties: the bending strength of these plates is ≥ 80 MPa, and an impact strength is ≥ 12 kJ/m (ASTM D 256), which is suitable for high-flow fields such as wall coating and retail displays, and ensures long-term durability.

- Enhanced Surface Characteristics: the surface is scratch-resistant (achieving a pencil hardness of 2 h), fingerprint-resistant, and easy to clean. Optional anti-bacterial treatments makes it ideal choice for medical care and hotels.

- Excellent Processing Adaptability: Decorative acrylic sheet can be laser cut, engraved, and thermoformed. The patterns remains clear and complete at the edges, allowing complex designs and custom shapes without sacrificing aesthetic quality.

- Environmental and Health Safety: Many products are LEED compliant, with VOC emissions of less than 0.1 mg/me and are formaldehyde-free, contributing to healthier indoor air quality (Source: U.S. Green Building Council LEED v 4.1 guidelines).

- Easy to install: This material is very light due to its density of 1.19 g/cm. Various methods can be used for installation, including double-sided tape, hidden screws or magnetic installation systems, thus simplifying the installation process.

What Are the main applications of decorative acrylic plates?

The versatility of decorative acrylic sheet enables it to be applied in many fields. Glittering acrylic boards might be most suitable for a retail display, while a wood grain pattern may be suitable for company office.

- Interior Design: used for characteristic walls, art room partitions, desktops, cupboard doors and LED backlight ceilings, creating eye-catching lighting effects.

- Commercial retail Spaces: used in brand image walls, sales window and point-of-sale counters to enhance brand image and customer participation. Flash acrylic tablets are especially effective in attracting attention in retail environment.

- Hotel Industry: used in hotel lobbies, restaurant partition and bar table, creating a unique and unforgettable atmosphere, and easy to maintain.

- Professional customization: this material is very suitable for high-end display of art installations, exhibition props, theme park decorations and luxury goods, where patterns and colors are often customized.

Technical Specifications and parameters

The following table provides the key technical data for decorative acrylic boards, which is very important for engineers and designers to verify the applicability of specific applications.

| Performance Index | Test Method | Typical Value |

| Density | ASTM D792 | 1.19 g/cm³ |

| Light Transmittance (Transparent Texture) | ASTM D1003 | 70-85% |

| Impact Strength (Unnotched) | ASTM D256 | 12 kJ/m² |

| Flexural Strength | ASTM D790 | 80 MPa |

| Heat Distortion Temperature | ASTM D648 | 80 °C |

| Vicat Softening Point | ASTM D1525 | 95 °C |

| Color Fastness | ISO 105-B02 | Grade 4-5 |

| Abrasion Resistance (Taber) | ASTM D1044 | 500 cycles |

What Factors affect the price of decorative acrylic plates?

Understanding the cost drivers of decorative acrylic sheet is helpful for budget planning and supplier negotiations.

- Raw Material Cost: PMMA resin price fluctuates with global oil prices. High-quality UV-stabilized resins are more expensive.

- Complexity of decorative Effect: Complex patterns, such as detailed marble texture or a high-density flash acrylic board, require more complicated manufacturing processes, thus increasing the price.

- Plate thickness and size: thicker plate (such as, 20 mm) and larger, custom-sized panels consume more material and energy, leading to a higher cost.

- Order Quantity: Bulk purchase usually enjoys a great discounts. Minimum Order Quantities (MOQs) are standard.

- Extra treatment: the Costs of pre-cutting, drilling, polishing edges or adding special coating such as antistatic layers will be added to the basic price.

- Logistics and shipping: Large, lightweight panels are voluminous, so shipping costs can be a substantial part of the total price, especially for international orders.

Supplier list: what to look for?

When purchasing decorative acrylic sheet, use this list to evaluate potential suppliers.

- Quality Certifications: Do they have quality management system certifications like ISO 9001?

- Material data sheet (MDS): Can they provide comprehensive technical data sheets and test results of ASTM/ISO standards?

- Sample Quality: always ask for physical sample to evaluate the accuracy of texture, color and overall completion. For flashing acrylic sheets, check the uniform distribution of flashing light.

- Customizability: verify whether they can adapt to customized sizes, patterns and colors to meet your specific design needs.

- Lead time and reliability: confirm the production lead times and track record of timely delivery.

- After-Sales Support: Inquire about their policy regarding claims for defective materials or shipping damage.

Frequently asked Questions and Answers

Q: What is the difference between a decorative acrylic board and a standard acrylic board?

A: The standard acrylic board is usually transparent or colored, but it lacks a complete textures or patterns. A decorative acrylic sheet has grain such as wood grain or marble, or embedded effects such as flash, which is mainly chosen because of its aesthetic value, without damaging the core strength of acrylic.

Q: Can the flash acrylic board be used for outdoor signs?

A: Although acrylic resin has good weather resistance, with the passage of time, the pigments in resin plate of Flash Acrylic may be easily degraded by ultraviolet rays, which may lead to fading. For long-term outdoor use, it is very important to choose a supplier who provides a stable versions of ultraviolet light and confirm the outdoor application warranty of the product.

Q : What is the standard size of acrylic sheet for decoration?

A: The most common standard size is 1220 mm x 2440 mm (4 ft x 8 ft). However, many manufacturers can custom-cut sheets to specific dimensions, such as 1220 mm x 1830 mm or smaller panels, though this may incur additional costs.

Q : How can I clean and maintain the decorative acrylic plate with texture?

A: Use a soft microfiber cloth dampened with water or a diluted solution of mild soap (like dish soap). Gently wipe the surface. Avoid using window cleaners, solvents or abrasive pads, because they can damage the texture and surface.

Q: Is decorative acrylic sheet fire-resistant?

A:Acrylic acid is a kind of flammable plastic. According to ASTM E 84, the surface burning characteristics of standard decorative acrylic sheet are classified as Grade B. For applications requiring higher fire resistance, look for specially formulated flame-retardant acrylic sheets that meet specific standards like UL 94 V-0 (Source: UL LLC Standard for Safety UL 94).

Summarize

In a word, the decorative acrylic board is a dynamic functional material, which combines the durability of PMMA with infinite design possibilities. From elegant marble finishes to vibrant shiny acrylic board options, it provides solutions for interior design, retail, hotels and customized art installations. The key to a successful project is to understand its technical specifications, such as impact strength and heat resistance, as well as the factors affecting its price. By following the list of suppliers provided and practical solutions for common problems, buyers can choose and use this material with confidence to create amazing, lasting and innovative spaces.

About us

Beijing Jingruite New Materials Co., Ltd. is a leading manufacturer and supplier of high-performance decorative acrylic sheet products. We specialize in a wide range of textures, including marble, wood grain, geometric patterns, and custom glitter acrylic sheet options. All our products have strict quality control, comprehensive technical support and a commitment to meet the specific design and performance requirements of customers. We provide customized cutting and production services to provide a perfect solution for your project.

Posts Categories

- Blogs22

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2