+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

A Comprehensive Guide to Special Thick Acrylic Sheet: Elevate Your Projects with High-Performance Transparent Materials

Introduction

When choosing transparent materials for building, decoration, advertising or industrial applications, it is very important to choose between glass and various plastic sheets. Among many available plastic materials, resin plate acrylate has been favored for a long time because of its optical transparency and versatility. However, for projects that need to enhance durability, stability and load-bearing capacity, thick acrylic sheets become a more reliable choice. And among these, Special thickacrylicsheet stands out as a high-performance solution that combines the advantages of standard acrylic with exceptional thickness-related properties. In this article, we will delve into what Special Thick Acrylic Sheet is, its unique advantages, technical specifications, main application scenarios, and answer common questions to help you make an informed purchasing decision.

What Is Special Thick Acrylic Sheet?

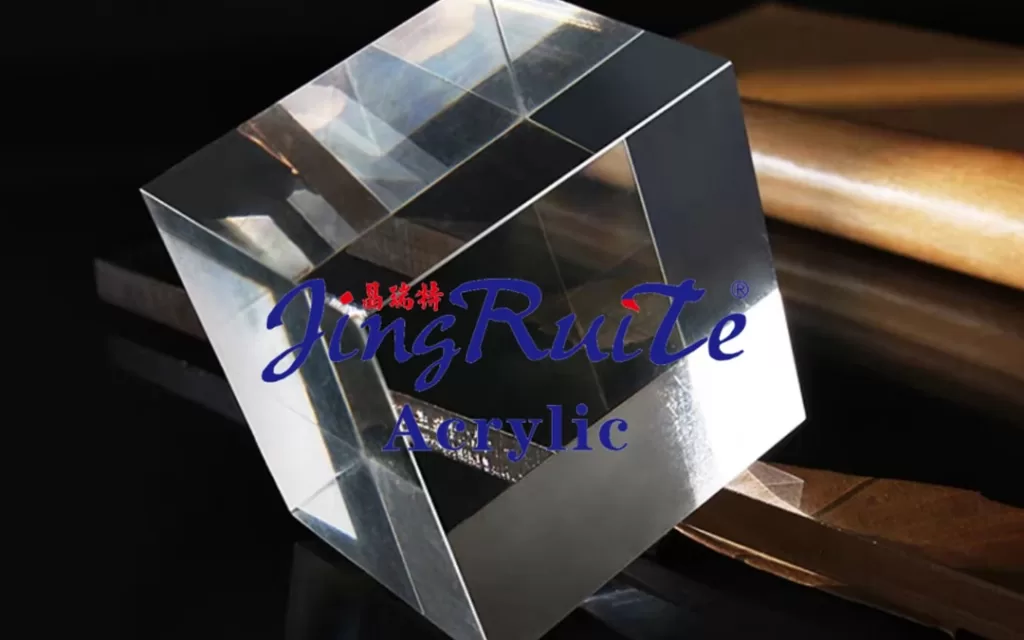

Extra-thick acrylic board is a kind of highly transparent material, which is made of 100% optical grade PMMA (polymethylmethacrylate) by casting or extrusion. PMMA, commonly called acrylic or plexiglass, is a thermoplastic polymer, which is famous for its excellent optical properties and mechanical strength. The design of “special thickness” makes it different from standard acrylic board. The standard acrylic board usually has a thinner thickness, providing a wider range of acrylic board thickness to meet high-demand applications.

Unlike ordinary thick acrylic sheet, Special Thick Acrylic Sheet undergoes rigorous production control to ensure uniform thickness, consistent optical performance, and superior surface quality. Its core definition revolves around three key attributes: optical grade raw materials, accurate thickness control and enhanced performance index. According to industry standards, the optical grade PMMA must meet strict requirements for light transmittance and haze, and the extremely thick acrylic board exceeds these requirements with a 92% light transmittance-comparable to optical glass.

Unique Advantages of Special Thick Acrylic Sheet

The popularity of Special Thick Acrylic Sheet stems from its array of unique advantages that make it a superior alternative to glass and standard acrylic sheets. These advantages have been supported by accurate test data and industry certifications, ensuring reliability in various applications.

1.Excellent optical properties

One of the most remarkable features of special thick acrylic sheet is its excellent optical transparency. It boasts a visible light transmittance of ≥ 92% (test method: ASTM D 1003), with a haze value of < 1% and no optical distortion. This means that even with greater acrylic sheet thickness (up to 300 mm), the material maintains excellent light transmission, making it ideal for applications where clarity is paramount, such as skylights and precision optical components. In contrast, the light transmittance of glass of the same thickness is often slightly lower due to surface reflections and internal impurities.

2.Excellent mechanical strength

Compared to traditional glass, Special Thick Acrylic Sheet offers significant advantages in terms of mechanical strength. The impact strength is 16 kJ/me (test method: ASTM D 256, notched Izod), which is 17 times that of glass. This makes it highly resistant to breakage, reducing the risk of damage from impact, vibration, or thermal shock. In addition, its tensile strength is 65 MPa (ASTM D 638) and its bending strength is 90 MPa (ASTM D 790), which makes it able to bear heavier loads than standard acrylic plate or glass of the same thickness. A study by the Plastics Europe Association found that thick acrylic sheet have a 40% higher load-bearing capacity than glass of equivalent thickness (source:Plastics Europe, accessed via official portal at https://www.plasticseurope.org; search for “PMMA load-bearing capacity” or “acrylic vs glass structural performance” for latest public reports ).

3.Light weight, easy to handle

Despite the enhanced strength, the special thick acrylic sheet is surprisingly light. Its density is 1.19g/cm (ASTM D792), which is 50% lighter than glass. This lightweight feature simplifies transportation, handling and installation and reduces labor costs and logistics challenges. For example, a 10 mm thick 1220 × 2440 mm Special Thick Acrylic Sheet weighs approximately 36 kg, while a glass sheet of the same size and thickness weighs around 72 kg .

4.Excellent Weather Resistance

Extra-thick acrylic sheet is designed to withstand harsh environmental conditions. It has a temperature stability range from -40℃ to 80℃, making it suitable for indoor and outdoor applications. The material is infused with UV stabilizers, ensuring that it does not yellow or degrade for up to 5 years when used outdoors .

5.Diverse processing flexibility

Another key advantage of Special Thick Acrylic Sheet is its processing flexibility. It can be thermoformed at temperatures of 140-160℃, and the minimum bending radius is 3 times the thickness of the material. This makes it possible to form various bent or customized forms to meet specific project requirements. In addition, it can be easily cut (laser cutting is recommended for accuracy), drilled, CNC carved, and bonded with solvent cement (based on dichloromethane) or UV curing adhesive. Its edge can also be polished by flame, diamond or sandblasting to achieve a smooth and professional appearance.

6.Environmental safety and compliance

Special Thick Acrylic Sheet is an environmentally safe material that complies with FDA food contact standards and is RoHS certified. It does not release formaldehyde or other harmful substances, making it suitable for food-related applications, medical facilities and indoor environment where air quality is concerned. Unlike some plastic materials, PMMA is recyclable, contributing to sustainable development.

Technical Specifications of Special Thick Acrylic Sheet

Understanding the technical parameters of Special Thick Acrylic Sheet is crucial for selecting the right product for your project. The following table summarizes the key technical specifications, as well as the corresponding test methods and values.

| Property | Test Method | Value |

| Light Transmission | ASTM D1003 | ≥92% |

| Density | ASTM D792 | 1.19 g/cm³ |

| Impact Strength (Notched Izod) | ASTM D256 | 16 kJ/m² |

| Tensile Strength | ASTM D638 | 65 MPa |

| Flexural Strength | ASTM D790 | 90 MPa |

| Heat Deflection Temperature | ASTM D648 | 85°C @ 264 psi |

| Water Absorption | ASTM D570 | ≤0.3% |

| Linear Thermal Expansion | ASTM D696 | 7×10⁻⁵ /°C |

| Surface Hardness | ASTM D3363 | 2H (Pencil Hardness) |

1.Size and thickness options

Special Thick Acrylic Sheet is available in standard sizes and customizable options to meet diverse project needs. The standard sizes are 1220 × 2440 mm and 1524 × 3048 mm. The acrylic sheet thickness range is extensive, from 1 mm to 50 mm, with common thicknesses including 1 mm, 2 mm, 3 mm, 5 mm, 8 mm, 10 mm, 15 mm, 20 mm, 30 mm, 40 mm, and 50 mm. Custom cutting is also supported, allowing you to obtain sheets of specific dimensions for your project.

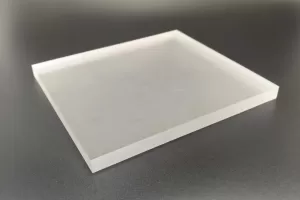

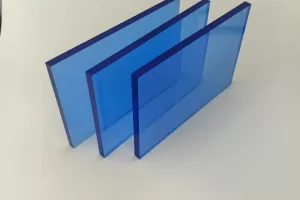

2.Surface options and packaging

To cater to different application requirements, Special Thick Acrylic Sheet offers various surface options, including clear, frosted, non-glare, and UV-resistant coating. Transparent surface provides the highest light transmittance, while the frosted surface provides privacy and a matte effect. The non-glare surfaces reduce reflections, making them suitable for display applications. All special thick acrylic sheet products are packaged with PE protective film on both sides to prevent surface scratches during transportation and handling. For large number of goods, use wooden pallets to ensure transportation safety.

The main application scenarios of extra-thick acrylic board

Thanks to its exceptional properties, Special Thick Acrylic Sheet is widely used in various industries and application scenarios. The following are the main application fields and specific use cases.

1.Construction and Decoration

In the field of architecture and decoration, Special thick acrylic sheet is a popular choice due to its transparency, strength, and lightweight properties. Its major applications include:

Daylighting project: Skylights, greenhouse panels and secondary glass. The high light transmittance of Special Thick Acrylic Sheet allows natural light to penetrate, creating bright and comfortable indoor environments. Its impact resistance also makes it suitable for use in places prone to hail or falling debris.

Interior Design: Shower curtains, furniture panels and room partitions. The smooth appearance and customizable shapes of this material add a modern flavor to indoor spaces. It is also easy to clean and maintain, and is very suitable for use in bathrooms and kitchens.

Building Curtain Walls: Transparent facade elements, canopies, and balustrades. Special Thick Acrylic Sheet reduces the weight of the building structure compared to glass, while still providing excellent wind resistance and load-bearing capacity.

2.Advertisements and exhibitions

The advertising and exhibition industry relies heavily on materials that can attract attention and effectively display products. Special thick acrylic sheet meets these requirements with its optical transparency and processing flexibility. Common applications include:

Signage: Illuminated signs, display cases, and point-of-purchase displays. The light transmission of this material enhances the brightness of the lighting signs, making them easier to see even in bright sunlight. Its durability ensures that these signs can withstand many years of outdoor weather conditions.

Retail: Product display shelves, cosmetics counters and jewelry display cases. Special thick acrylic sheet provides a clear view of the products, highlighting their features and details. It also has scratch resistance, maintaining a clean and professional appearance.

Exhibition: trade exhibition booths, light boxes and promotional displays. The material’s lightweight and easy-to-process properties make it ideal for creating temporary or permanent exhibition displays. It can be cut quickly and shaped into various forms to match the design theme of the booth.

3.Industrial and special Applications

In industrial and special fields, Special Thick Acrylic Sheet is valued for its high performance and compliance with strict industry standards. Its major applications include:

Medical equipment: surgical instrument trays, medical equipment shell and hospital partition. The biocompatibility of this material and its compliance with FDA standards make it safe to be used in medical environment. It is also easy to disinfect, reducing the risk of cross contamination.

Electronic products: Display screens, touch screen and protection covers. Special thick acrylic sheet offers excellent optical clarity and scratch resistance, making it suitable for use in electronic devices such as smartphones, tablets, and industrial control panels.

Optical Applications: Lenses, light guides, precision instruments. The low optical distortion and high transmittance of this material make it an ideal choice for optical elements that need precise optical control.

Processing and Installation Guidelines for Special Thick Acrylic Sheet

To ensure the best performance of Special Thick Acrylic Sheet, proper processing and installation are essential. The following are step-by-step guidelines for common processing and installation methods.

Cutting

1. Prepare the Special Thick Acrylic Sheet by removing the protective film from the area to be cut (keep the film on the rest of the sheet to prevent scratches).

2. Mark the cutting line with a marker or scriber. For straight-line cutting, use a straight edge to ensure accuracy.

3. Select the appropriate cutting tool: It is recommended to use laser cutting for precision cutting, especially for cutting with complex shapes or thin acrylic plate thickness. For thicker plates, a circular saw with fine-toothed blade (100-120 teeth) can be used.

4. Cut the thin plate at a slow and steady speed to avoid the edge from melting or breaking. For laser cutting, the power and speed are adjusted according to the plate thickness.

5. After cutting, use sandpaper (starting from coarse grain size and gradually becoming fine grain size) or a file to polish the edge.

Thermal forming

1. Preheat the oven to 140-160℃. The exact temperature depends on the thickness of the acrylic plate (thicker plates need higher temperatures and longer heating times).

2. Place the special thick acrylic sheet in the oven and heat it until it becomes flexible (typically 5-15 minutes, depending on thickness).

3. Remove the sheet from the oven using heat-resistant gloves and place it over the mold.

4. Use a vacuum forming machine or by applying mild pressure to form the sheet to fit the mold. Ensure that the plate is stretched evenly to avoid thinning or deformation.

5. Allow the board to cool completely (at least 30 minutes) before taking it out of the mold.

Adhesion

1. Clean the surface to be bonded with a solvent (such as isopropanol) to remove dust, oil and other pollutants.

2. Choose a suitable adhesive: It is recommended to use solvent cement (dichloromethane-based) for permanent bonding, while ultraviolet curing adhesives is suitable for applications requiring rapid curing and high transparency.

3. Apply a thin, even layer of adhesive to one of the surfaces using a brush or syringe.

4. Align the two surfaces and press them together with force. During the curing process, the surface is fixed in place by using clips or weights.

5. Allow the adhesive to cure completely according to the manufacturer’s instructions (solvent cement typically cures in 24 hours, while UV-curing adhesives cure in a few minutes with UV light).

Installation

1. According to the application, determine the installation method: mechanical fasteners (such as screws with washers), adhesive installation or edge clamping.

2. For mechanical fasteners: Drill pilot holes in the Special Thick Acrylic Sheet (the diameter of the pilot hole should be slightly larger than the diameter of the screw to allow for thermal expansion). A washers is placed between the screw and the thin plate to distribute the pressure and prevent the crack.

3. For adhesive installation: Clean the installation surface and the back of the paper. Apply a high-quality acrylic adhesive to the back of the sheet and press it firmly against the mounting surface. Fix it in place with clips or weights until the adhesive cures.

4. For edge clamping: use aluminum or stainless steel fixture to fix the edges of the thin plate to the frame. Make sure that the clamps spacing is even, and do not apply excessive pressure, otherwise the sheet will be damaged.

Frequently Asked Questions and Answers

In order to solve the common problems that users may encounter when purchasing and using special thick acrylic sheets, we have compiled the following FAQ section.

Q: What is the difference between Special Thick Acrylic Sheet and standard acrylic sheet?

A: the main difference lies in the thickness and properties of acrylic sheet. Special Thick Acrylic Sheet has a thicker gauge (up to 50 mm) and undergoes stricter production control to ensure uniform thickness and consistent performance. It also has higher mechanical strength, better load-bearing capacity, and superior weather resistance compared to standard acrylic sheets. Standard acrylic sheets are typically thinner (≤ 10 mm) and are suitable for general-purpose applications, while Special Thick Acrylic Sheet is designed for high-demand applications that require enhanced durability.

Q: How to choose the appropriate thickness of acrylic board for my project?

A: the choice of acrylic sheet thickness depends on several factors, including the application, load-bearing requirements, and environmental conditions. For indoor applications, such as display cabinets or furniture panels, a thickness of 3-10 mm is usually sufficient. For outdoor applications, such as skylights or canopies, it is recommended that the thickness be 10-20mm to resist wind, rain and impact. For industrial or heavy applications, such as machine protection devices or optical components, a thickness of 20-50 mm may be required. It is also important to consider the span of the plate-the larger the span, the thicker the plate to prevent sagging.

Q: Is Special Thick Acrylic Sheet resistant to UV radiation?

A: Yes, Special thick acrylic sheet is infused with UV stabilizers during production, which makes it resistant to UV radiation. It can withstand up to five years of outdoor exposure without yellowing, cracking or degradation.For applications that require long-term outdoor use (more than 5 years), we recommend choosing the anti-ultraviolet coating option, which provides extra protection against ultraviolet radiation.

Q: Can special thick acrylic sheets be recycled?

A: Yes, the special thick acrylic board is made from PMMA, which is a kind of recyclable thermoplastic. It can be melted and reused in the production of new acrylic products. However, it is important to separate it from other plastics in the recycling process to ensure the quality of the recycled material. Many recycling facilities accept PMMA, and some manufacturers offer take-back programs for used acrylic sheets.

Q: How to clean and maintain Special Thick Acrylic Sheet?

A: To clean Special Thick Acrylic Sheet, use a soft cloth (such as a microfiber cloth) and a mild detergent or acrylic cleaner. Avoid using abrasive cleaning agents, scouring pads or solvents (such as acetone or gasoline), which can scratch or damage the surface. Rinse the paper with water and dry it with a soft cloth to prevent water stains. For regular maintenance, check the plate regularly for scratches or damage, and use polishing agent specially designed for acrylic acid to repair it in time.

Summary

Special Thick Acrylic Sheet is a high-performance material that offers a unique combination of optical clarity, mechanical strength, lightweight properties, and processing flexibility. Its wide range of acrylic plate thickness, diverse surface selection and compliance with environmental and industrial standards make it suitable for a wide range of applications from architecture and decoration to advertising and industrial use. By understanding its definition, unique advantages, technical specifications, application scenarios and processing guide, you can choose the right thick acrylic board for your project and ensure the best performance.

Whether you are looking for a glass substitute for a skylight, a durable material for a retail display, or a high-precision component for a medical equipment, special thick acrylic sheet are reliable and economical solution. With its excellent performance and mature performance, it is not surprising that it has become the first choice for professionals in all industries.

Posts Categories

- Blogs22

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2