+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

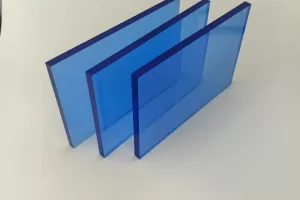

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

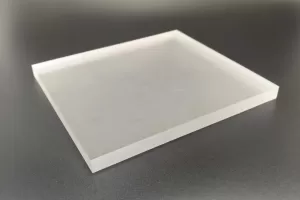

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

How to choose a suitable acrylic board for your LED lighting project?

LED lighting technology has completely changed our way of spaces lighting, but the quality of light distribution largely depends on the materials used. The acrylic sheet for lighting lamp is an important part of creating uniform and glare-free lighting across various applications. This special optical material combines the durability and advanced light diffusion characteristics of acrylic resin, which makes it indispensable material in modern lighting designs.

Key Advantages of led acrylic sheets

Light distribution of the whole surface is consistent

Compared with the diffuse LED light source, the glare is reduced by 70-80%.

Color rendering is accurate and distortion is minimal

Industry testing confirms that high-quality light diffuser acrylic sheet can achieve a spot shielding rate of ≥ 99%, effectively eliminating the bright points typically associated with individual LEDs (Source: International Commission on Illumination CIE 205: 2013).

Improve durability and security

The thermal stability of the material (thermal deformation temperature ≥ 85℃) can prevent warping or deformation during long-term use, thus ensuring consistent optical properties for a long time.

Weather-Resistant Performance

led acrylic sheet products have excellent weather resistance and can work reliably in temperatures range of -40℃ to 90℃. The incorporation of UV stabilizers provides protection against yellowing, with color shift measurements (Δ E) remaining below 3 even after 5,000 hours of continuous operation.

Product Series and Specifications

1.Diffuser Panels: Engineered for general lighting applications, these panels excel at creating uniform light distribution by effectively eliminating glare and hot spots.

2.Light Guide Plates (LGP): Specifically designed for edge-lit configurations, they precisely control and guide light from the edges to achieve consistent brightness across the entire surface.

3.Uniform Light Panels: Tailored for applications demanding the highest level of luminance homogeneity, these panels deliver a perfectly even and smooth visual surface with no variation.

The standard thickness ranges from 1.5 mm to 10 mm, and the most common paper size being 1220 × 2440 mm Manufacturers usually provide customized dot pattern design to optimize light extraction for specific applications.

Performance measurement standard

Comprehensive test of light diffuser acrylic sheet shows that the performance across key parameters is consistent.

| Parameter | Standard Value | Testing Standard |

| Light Transmittance | 85-92% | ASTM D1003 |

| Haze | 90-98% | ASTM D1003 |

| Impact Strength | 16kJ/m² | ISO 179 |

| Heat Distortion Temperature | ≥85℃ | ASTM D648 |

| Yellowing Resistance | ΔE<3 @5000hrs | ISO 4892 |

Cross-industry applications

Commercial lighting and architectural lighting

According to a market analysis by Research and Markets, the global market for advanced lighting materials will reach $ 3.2 billion in 2024, of which LED light acrylic boards will account for about 28% of this market segment (source: Research and Markets, “Market Report of Advanced Optical Materials”, 2024).

Retail and display applications

Light diffusion acrylic technology has changed visual goods and signs. Using these materials, ultra-thin light boxes can realize vivid advertisement displays with uniform backlight, while retail environment can use them for brand logo lighting and direction sign. The consistency of materials ensures that brand colors remains true in many installations and maintains the company’s identity standards.

Professional industrial Uses

In addition to the traditional lighting, acrylic sheet for lighting plays an important role in professional fields.

Medical lighting: the surgical lamp using led acrylic sheet technology can reduce the shadow by more than 90% and improve the visibility of the surgical process.

Agricultural Applications: the plant growth systems combines customized diffusion properties to optimize the distribution of photosynthetic effective radiation (PAR).

Ultraviolet treatment: the special formula can safely transmit ultraviolet rays for sterilization and curing.

Manufacturing and customization capability

Advanced processing options

The versatility of LED light acrylic board extends to its manufacturability. This material supports a variety of manufacturing technologies, including:

Precision laser cutting for complex shapes.

Computer numerical control engraving of customized optical patterns.

Hot forming for bending applications.

Surface printing in the design of integrated circuit.

These processing options enable lighting designers to customize the solutions for specific projects without affecting the optical performance.

Quality and compliance Standards

Well-known manufacturers ensure that led acrylic sheet products meet international standards, including RoHS and REACH regulations. Other certifications generally include:

Halogen-free material composite;

Low VOC (volatile organic compound) emissions;

Fire resistance ratings applicable to building codes.

Frequently asked Questions and answers

Q:What’s the difference between LED light acrylic board and ordinary acrylic board?

A:Unlike standard acrylic board, the acrylic board of LED lamp contains special diffusing particles, which can scatter light evenly. The haze value of conventional acrylic resin is usually lower than 5%, while that of diffuse acrylic resin can reach 90-98%, while maintaining high light transmittance.

Q:How does thickness affect the properties of acrylic sheets for lighting?

Thicker light diffuser acrylic sheet materials (≥ 3 mm) generally provide better diffusion but may reduce overall light output by 5-8%. Thinner board (1.5-2mm) provides higher brightness, but more accurate LED spacing may be needed to achieve uniform illumination.

Q:Can led acrylic sheet materials be used outdoors?

A:Yes, UV-stabilized formulations of led acrylic sheet are suitable for outdoor applications. Although exposed to sunlight and temperature fluctuations for a long time, these special materials still maintain their optical properties and mechanical integrity.

Q:What is the typical service life of acrylic sheet for LED lamps?

A:Under normal indoor conditions, high-quality acrylic board for LED lamps has maintained its optical performance for more than 10 years. Accelerated aging tests shows that after 5000 hours of continuous exposure to ultraviolet rays, the yellowing (δE) remains below 3.0, which is equivalent to outdoor use for about 5-7 years.

Q:Do you have custom-made sizes and styles of acrylic sheets for lighting?

A:Most manufacturers offer a wide range of customization options for acrylic sheet for lighting, including customized sizes, thicknesses and optical patterns. Customized dot patterns can optimize light extraction for specific LED configurations and application requirements.

Posts Categories

- Blogs16

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2