+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

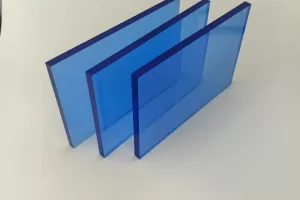

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

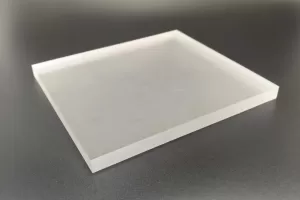

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

How to Choose the right sound barrier acrylic sheet: a complete guide.

Introduction

When it comes to reducing noise pollution, while maintaining visual clarity, sound insulation acrylic board has become a revolutionary solution. This comprehensive guide provides you with everything you need to know about acrylic noise barrier technology, from its manufacturing process and technical specifications to application scenarios and selection criteria.

What is a soundproof acrylic sheet?

Acoustical acrylic board is a special transparent board, which aims to reduce noise transmission and maintain good visual characteristics. As an effective sound barrier, this advanced material combines the transparency of glass with the excellent noise reduction ability. Different from traditional sound barriers, these boards use multi-layer technology to absorb and suppress sound waves, making them ideal choice for applications where noise control and visibility are crucial. Acoustical acrylic board represents a great progress in acoustic materials, which provides a modern alternative to the traditional opaque barriers and meets the increasing demand for beautiful noise control solutions in urban environment.

Key Features of Soundproof Acrylic Sheets.

1. Excellent acoustic performance: These boards can achieve noise reduction effect of 30-35 dB in the frequencies range of 100-5000 Hz, making them very effective for traffic, industrial and commercial noise control. The unique composition of sound insulation acrylic board makes it more effective in absorbing and suppressing sound waves than standard acrylic board or glass board.

2. Structural durability: the sound-proof acrylic board is designed to withstand extreme conditions, and its impact strength is ≥ 15 kJ/me, and it can withstand typhoon-level winds. This combination of strength and clarity makes the soundproof acrylic sheet a preferred choice for exterior applications where weather resistance is paramount.

3. Weather and UV Resistance: Designed for long-term outdoor use, the soundproof acrylic sheet performs reliably in temperatures from -40℃ to 80℃ and includes UV protection that prevents yellowing for at least 5 years. This durability ensures that the sound-proof acrylic board keeps its aesthetic and functional characteristics for a long time.

4. Enhanced Safety Features: Many sound barrier acrylic sheet products incorporate bird-strike prevention designs, typically featuring surface patterns that are visible to birds while maintaining human transparency. This thoughtful design element demonstrates how the sound insulation acrylic board can solve many environmental problems at the same time.

5. Fire Safety Compliance: Most quality sound barrier acrylic sheet products achieve UL 94 V-0 fire rating, making them suitable for applications with strict fire safety requirements. This certification ensures that sound-proof acrylic boards can be widely used in commercial and public facilities.

6. Customizable Sizing: Available in standard dimensions of 2440 × 1220 mm and 3000 × 1500 mm, with thickness options ranging from 10 mm to 25 mm, the soundproof acrylic sheet offers flexibility for various project requirements.

Technical Specifications

| Parameter | Specification | Testing Standard |

| Thickness Range | 10mm-25mm | ASTM D1003 |

| Standard Panel Sizes | 2440×1220mm, 3000×1500mm | Custom sizes available |

| Sound Reduction Index (Rw) | 30-35 dB | ISO 10140, ASTM E90 |

| Weighted Sound Reduction | 30-35 dB(A) | ISO 717-1 |

| Light Transmittance | ≥85% | ASTM D1003 |

| Impact Strength | ≥15 kJ/m² | ASTM D256 |

| Wind Load Resistance | ≥2400 Pa | ASTM E330 |

| Fire Rating | UL94 V-0 | UL 94 Standard |

| Service Temperature Range | -40℃ to 80℃ | ASTM D1790 |

| Expected Service Life | 15+ years (outdoor) | Accelerated weathering tests |

| Density | Approximately 1.2 g/cm³ | ASTM D792 |

Price Factors for Soundproof Acrylic Sheets.

1. Thickness and size: the price of sound insulation acrylic board will increase with the increase of thickness, because thicker boards need more materials and provide better acoustic performance. Standard sizes sound insulation acrylic board is usually more cost-effective than custom size, and custom size may involve additional manufacturing and installation costs.

2. Acoustical performance Requirements: A higher sound transmission level (STC) in the sound insulation acrylic board usually corresponds to higher costs. Panels rated at 35 dB typically cost 20-30% more than 30 dB-rated soundproof acrylic sheet products. (source: Acoustics Material Association Pricing Survey, 2024.

3. Surface Treatments and Features: the additional features of the sound-proof acrylic board, such as anti-ultraviolet coatings, anti-scratch surface or anti-bird pattern, will increase the manufacturing cost, but will prolong the life and function of the product.

4. Order Volume and Customization: Larger projects using soundproof acrylic sheet benefit from volume discounts, while custom colors, patterns, or specialized formulations increase the per-unit cost of soundproof acrylic sheet.

5. Installation Requirements: the total cost of a soundproof acrylic sheet project includes not just the material but also framing systems, hardware, and installation labor. Complete sound insulation acrylic panel systems with integrated installation solutions may have higher upfront costs, but lower long-term cost.

Frequently asked Questions and answers

Q: What maintenance is needed for the installation of sound insulation acrylic board?

A: the sound insulation acrylic board requires the least maintenance. Regular cleaning with mild soap and water is usually enough to keep optical transparency. Avoid using abrasive cleaning agents or solvents to avoid damaging the surface of sound insulation acrylic board. The UV-resistant formulation of quality soundproof acrylic sheet prevents yellowing, and the material’s inherent durability resists scratching and environmental degradation. Most soundproof acrylic sheet installations only require annual inspection of mounting hardware and seals.

Q: Can the sound-proof acrylic board be used in bending or custom-shaped applications?

A: Yes, the sound insulation acrylic board can be thermoformed into curved surfaces for building and design applications. The thermoforming process of sound insulation acrylic board includes heating the material to a flexible temperature, and then forming it over a mold. This property enables the sound-insulating acrylic board to be used in bending barriers, cylindrical housings and other non-planar applications, while maintaining its acoustic and optical characteristics.

Q : How to install the sound insulation acrylic board and what support systems are needed?

A: Acoustical acrylic panels are usually installed in aluminum or steel frame systems, using special washers and installation hardware. The installation process of soundproof acrylic sheet includes: 1) preparing supporting structure, 2) Installing rubber or neoprene gaskets in the frame, 3) putting sound-proof acrylic board into the frame, 4) fixing it with appropriate fasteners, and 5) sealing the joint with compatible sealants. Correct installation is very important to the performance of sound insulation acrylic board, especially in weatherproofing and sound insulation.

Q : What impact will the production and treatment of sound insulation acrylic board have on the environment?

A: Modern sound-proof acrylic sheet manufacturing significantly reduces the environmental impact by improving production efficiency and material utilization. Most sound insulation acrylic products are recyclable, although recycling infrastructure varies from region to region. The sound insulation acrylic board has a long service life (more than 15 years), which reduces the replacement requirement and related environmental costs. When evaluating sound insulation acrylic board products, look for manufacturers with environmental management certifications (ISO 14001) and responsible recycling plan.

Q : Compared with other sound insulation materials, what is the cost of the sound insulation acrylic board?

A: At first, the cost of soundproof acrylic sheet is usually higher than that of opaque barriers such as concrete or wood. However, when the total life cycle cost (including installation, maintenance and replacement) is taken into account, the sound insulation acrylic board is usually more economical. Compared with the concrete barrier, the lightweight characteristics of the sound insulation acrylic board reduce the structural support requirements and installation time by about 40%. In addition, the durability and low maintenance cost of sound insulation acrylic board reduce long-term costs, and the research shows that compared with traditional materials, the five-year cost can be saved by 25-35%. (source: Construction Materials Cost Analysis Journal, 2024)

Q: Can soundproof acrylic sheet be combined with other materials for enhanced performance?

A: Yes, sound insulation acrylic boards are often used in composite systems together with other materials. Common combinations include: 1) Soundproof acrylic sheet with aluminum frames for structural support, 2) Soundproof acrylic sheet backed with absorptive materials for improved low-frequency performance, and 3) soundproof acrylic sheet integrated with ventilation systems in specialized applications. These hybrid systems make use of the transparency of sound insulation acrylic board, and at the same time solve the specific acoustic or structural requirements that can not be provided by independent sound insulation acrylic board.

Summary

Acoustical acrylic board represents a great progress in noise control technology, combining effective acoustic performance with visual transparency and structural durability. This innovative material can reduce the noise by 30-35 dB, while maintaining the light transmittance above 85%, which is very suitable for applications where noise control and visibility are very important. Acoustical acrylic board is about 50% lighter than glass, and can withstand extreme weather conditions. Its service life can reach more than 15 years, and it requires minimal maintenance. From highway guardrails and building facades to industrial fences and commercial spaces, sound insulation acrylic panels provide an effective solution to urban noise pollution, while retaining visual contact with the environment. With the cities constantly coping with the challenge of noise pollution, sound insulation acrylic board technology provides a balanced method, which takes both acoustic performance and aesthetic considerations into consideration in modern urban design.

Posts Categories

- Blogs16

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2