+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

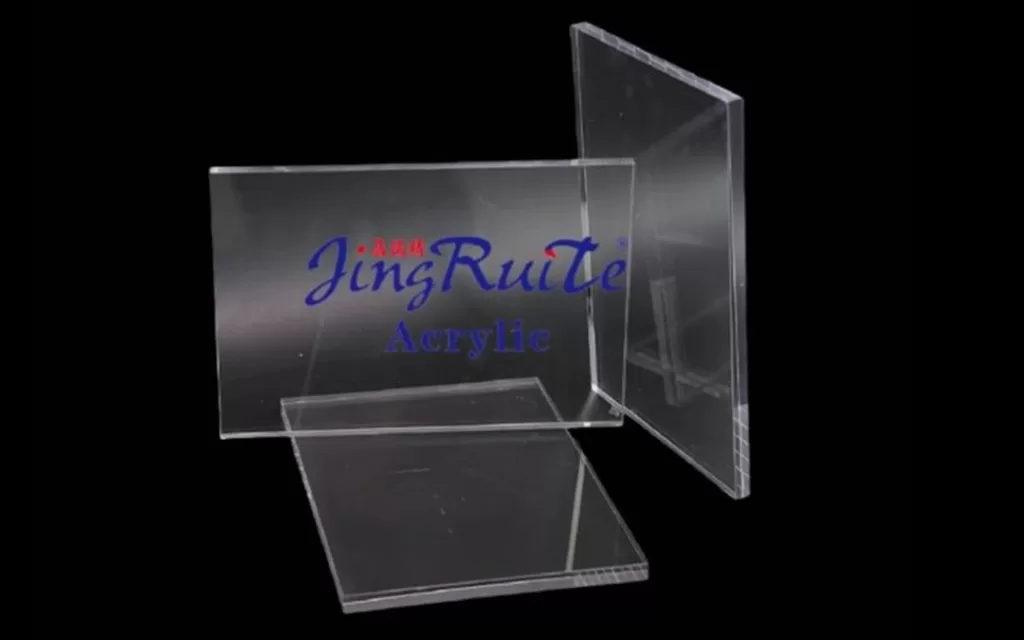

- Clear Acrylic Sheet

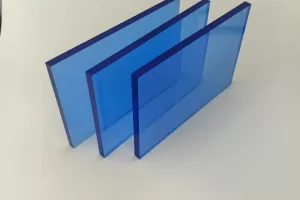

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

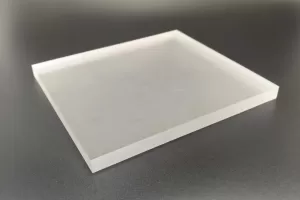

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

UV Transmitting Acrylic Sheet vs Standard Acrylic Sheet: Full UV Transmission Performance Comparison

Brief introduction

Acrylic board is widely used in all walks of life because of its excellent transparency, light weight and machinability. However, they differ significantly in ultraviolet (UV) light transmission: UV transmitting acrylic sheet and standard acrylic sheet are suited to distinct applications due to this difference. For professionals working on UV-reliant projects—such as medical phototherapy, industrial UV curing, agricultural greenhouses, and precision scientific instruments—understanding these differences is essential to ensure project efficacy, long-term performance, and cost-effectiveness.

This guide compares UV transmitting acrylic sheet and standard acrylic sheet in core performance, specifications, applications, usage precautions, and selection criteria. Supported by authoritative industry data with clear citations, it highlights the unique value of UV transmitting acrylic sheet—a high-performance new materials in optical acrylic—to help readers grasp its competitive edge in UV-focused applications.

Defining the Two Acrylic Sheet Types: Core Differences at a Glance

In order to fully understand the performance differences between the UV transmitting acrylic sheet and standard acrylic board, it is necessary to clarify their basic definitions, design goals and manufacturing differences. These basic features determine all aspect of their functions and applicability.

What is UV Transmitting Acrylic Sheet?

UV transmitting acrylic sheet is a specialized optical grade polymethyl methacrylate (PMMA) sheet engineered for efficient UV transmission. Different from standard acrylic resin (focused on visible light transparency and general use), it preferentially passes through UV-A (320-400 nm) and UV-B (280-320 nm), while maintaining high definition of visible spectrum (400-700 nm).

It is made of 100% pure MMA (methyl methacrylate) to ensure batch consistency and long-term reliability, which is very important for applications that rely on ultraviolet rays. It can provide a thickness of 1 mm-50 mm, and the standard sizes are 1220 × 2440 mm and 1000 × 2000 mm, which is suitable for various engineering scales (source: ASTM International, standard specification for optical grade acrylic board)

What is standard acrylic sheet?

Standard acrylic board (universal PMMA) has been paid attention to because of its cost-effectiveness, high visible light transparency and moderate impact resistance. Typically made of virgin-recycled MMA blends (pure virgin for high-grade variants), it is designed for applications without UV transmission needs.

A key trait is its inherent UV absorption: UV stabilizers are added to block most UVA and UVB, preventing yellowing and degradation outdoors. While enhancing general-purpose longevity, this makes it unsuitable for UV-reliant projects (source: Polymer Science and Technology, 2024, Vol. 33, the second issue) Common uses include signage, display cases, architectural glazing, and decorative goods.

Core performance comparison: Pay attention to ultraviolet transmittance & key performance

UV transmission performance: the key difference

| Parameter | UV Transmitting Acrylic Sheet | Standard Acrylic Sheet (General-Purpose Grade) | Test Standard/Remarks |

| UV-A Transmittance (320-400nm) | ≥90% (at 3mm thickness) | 30%-50% (at 3mm thickness) | |

| ASTM G140-23 | |||

| Visible Light Transmittance (400-700nm) | ≥92% | 90%-92% | Optical performance test |

| Haze Value | <1% | 1%-2% | Optical uniformity indicator |

| Surface Quality | 60/40 (scratches/pits) | 40/20 (scratches/pits) | Surface defect standard |

| Thickness Range | 1mm – 50mm | 1mm – 30mm | Standard available range |

| Standard Size | 1220×2440mm, 1000×2000mm | 1220×2440mm, 1500×3000mm | Common sheet dimensions |

| Impact Strength | 10 times that of glass | 8-10 times that of glass | Mechanical performance test |

| Flexural Strength | ≥70MPa | 60-70MPa | Mechanical performance test |

| Continuous Operating Temperature | -40℃ ~ 70℃ | -30℃ ~ 60℃ | Thermal stability range |

| Radiation Resistance | ≥1000kGy | Not specified | UV-resistant application indicator |

| Processing Adaptability | Thermoformable (140-160℃), cuttable, drillable, polishable, coatable | Thermoformable (140-160℃), cuttable, drillable, polishable | Processing performance |

Optical transparency: uniformity and basic transparency

Both UV transmitting acrylic sheet and standard acrylic sheet offer high visible light transparency, but there are key differences in optical uniformity—a critical factor for precision applications. UV transmitting acrylic sheet boasts a visible light transmittance of ≥ 92% (400-700 nm) and a haze value of < 1%, with a surface quality rating of 60/40 (scratches/pits). This low haze and high surface uniformity ensure the minimum light scattering, which makes it very suitable for applications where clear visual observation is consistent with ultraviolet transmission, such as the sample cell of fluorescence spectrometer or the observation window of ultraviolet aging test box.

In contrast, the standard acrylic board usually provides 90% -92% visible light transmittance and 1% -2% haze value, and the general grade surface quality grade is 40/20 (scratches/pits). Although this level of resolution is sufficient for most non-precision applications (e.g. Signs, decorative plates), high haze and low surface uniformity can lead to slight deformation or turbidity, making it unsuitable for precision optical equipment.

Weather Resistance & Long-Term Stability

Weathering resistance is a key consideration for outdoor applications or any environment exposed to harsh conditions for a long time. These two materials achieve weatherability with different formulas, reflecting their different design goals.

Curing Applications: used in Windows of UV adhesive/ink curing equipment. ≥ 90% uV-A transmission accelerates curing, improving production efficiency and product durability.

Standard Acrylic Sheet: Relies on UV stabilizers to block UV radiation, which helps resist yellowing for 2-3 years in outdoor environments. However, its mechanical strength (for example. When exposed to extreme temperatures, humidity or sunlight for a long time, impact resistance and bending strength) degrade faster than ultraviolet-transmissive acrylic sheets.

Application Scenarios: Matching Material to Purpose

- Art lighting: ultraviolet fluorescent pigment excitation lamps. Efficient UV transmission enhances artwork vibrancy, with low heat emission protecting art.

- Analytical Instruments: Employed as sample cells in fluorescence spectrometers and UV-visible spectrophotometer. The low haze value and high ultraviolet transmission uniformity ensure the consistent interaction between ultraviolet light and the samples, and eliminate the measurement errors caused by light scattering or uneven transmission.

- Sterilization equipment: Used as protective covers of ultraviolet disinfection lamps (in medical institutions, food processing plants and water treatment systems) and the components of ultraviolet water treatment reactors. High ultraviolet transmittance ensures the best disinfection effect, and at the same time, the impact resistance of the material can prevent damage during installation, maintenance or accidental contact.

- Agricultural Technology: Employed as panels for UV-enhanced plant growth lamps and as transparent coverings for specialized greenhouses. Ultraviolet light plays an important role in photosynthesis, nutrient absorption and pest resistance of plants, which makes the high ultraviolet transmittance of ultraviolet-transmitting acrylic board crucial for maximizing crop yield and quality. The weather resistance of the material also ensures its long-term performance in outdoor agricultural environment, and it can withstand hail, wind and long-term sunlight exposure.

The use of precautions and selection guidelines

Precision optical applications: UV transmitting acrylic sheet (1 mm-3 mm for optimal uniformity; Verifying the surface quality of 60/40.

General purpose, no need for ultraviolet rays: standard acrylic resin (2mm-5mm for signs/displays, 5mm-10mm for glass).

Basic demand sensitive to cost: standard acrylic resin (avoid using < 3 mm in high traffic environment; Choose enhanced UV-stabilized grades for outdoors).

Safety Protection: ultraviolet rays passing through the board can cause harm to human skin and eyes. When installing, maintaining or operating the equipment using the UV transmitting acrylic sheet be sure to wear UV-protective glasses and gloves to prevent direct exposure.

Cleaning and Maintenance: Use only specialized acrylic cleaners (formulated for optical grade materials) to clean the sheet. Avoid using irritating solvents such as alcohol, acetone or gasoline, because these solvents can damage the surface, cause turbidity, or reduce the ultraviolet transmittance. Please use a soft lint-free cloth during daily cleaning to avoid scratching the surface.

Processing restrictions: When thermoforming UV-transparent acrylic sheets, strictly control the temperature within the range of 140-160℃. Exceeding this temperature range can lead to thermal degradation and reduce the ultraviolet transmission efficiency and mechanical strength. Use sharp, high-quality tools to cut and drill holes to avoid cutting edges.

Selection guiding principles

Standard thickness: 1 mm -50 mm. Some manufacturers can provide customized thickness as high as 100 mm (longer lead times and higher costs).

The choice hinges on UV transmission needs: For UV-A/UV-B-reliant applications, UV – transmitting acrylic sheet—a high-performance new material—is the only viable option. Its excellent ultraviolet transmittance, uniformity, weatherability and mechanical stability make it indispensable material in the fields of medical phototherapy and semiconductor manufacturing.

Precision optics applications (such as Spectrometers, lithography): Select UV transmitting acrylic sheet with 1 mm-3 mm thickness for optimal optical uniformity and minimal light absorption. Verify the surface quality grade of the material (60/40 scratches/pits) to ensure that it meets the accuracy requirements.

For detailed specifications, customized solutions or application support of UV transmitting acrylic sheet, please consult the famous optical acrylic manufacturer and customize the materials according to the project requirements.

Cost-sensitive projects with basic glass or decoration needs: select standard acrylic board. Avoid thicknesses below 3 mm for high-traffic environments, as they may be prone to damage. For outdoor applications, the grade with enhanced UV stabilizers is selected to prolong the service life.

Fequently Asked Questions

The following are answers to common questions about UV transmitting acrylic sheet and standard acrylic board, which have solved the main problems that professionals often encounter in the process of material selection and application.

Q: Can standard acrylic board be modified to transmit ultraviolet light?

A:No. The UV-blocking property of standard acrylic sheet is inherent to its formulation, including the UV stabilizers added during manufacturing. Modifications such as sanding, coating, or heating will not significantly improve UV transmission and may instead damage the material’s optical clarity or mechanical strength.

For applications requiring UV transmission, UV-transparent acrylic plate-designed with professional UV transparent formula-is the only reliable choice (source: Polymer Science and Technology, 2024).

Q : Is UV transparent acrylic sheet more expensive than standard acrylic board?

A:Yes. Due to the use of 100% pure MMA raw material and special anti-aging/ultraviolet transparent formula, the ultraviolet transparent acrylic board is usually 30% -50% more expensive than standard acrylic board. However, this cost premium is reasonable for applications where ultraviolet transmission performance is critical, such as medical equipment, precision manufacturing or agricultural systems, because in these applications, the performance of standard acrylic sheets may not be enough.

Q: How long does the ultraviolet transmission performance of ultraviolet-transmissive acrylic sheet last?

A:Under proper storage and usage conditions, UV transmitting acrylic sheet maintains at least 85% of its original UV transmission performance for 5+years. After 3 years of continuous outdoor exposure, performance degradation (including UV transmission and optical clarity) is less than 5% —significantly better than standard acrylic sheet in UV-exposed environments (source: International Society for Optics and Photonics, 2025). Periodic maintenance (e.g. G proper cleaning (avoiding irritating chemicals) can further prolong its service life.

Q : Can UV transmission acrylic board be thermoformed into a customized shapes?

A:Yes, the UV-transmitting acrylic board provides good processing adaptability, including thermoforming, cutting, drilling, polishing and coating. Thermoforming should be carried out in the temperature range of 140-160℃ to ensure that the material maintains its ultraviolet transmittance and mechanical strength. For complex shapes or precision parts (e.g. Lithography system components), it is suggested to cooperate with manufacturers specializing in optical acrylic processing to ensure the consistency of dimensional accuracy and performance.

Q : What is the maximum thickness of the UV transmitting acrylic sheet?

The standard thickness of UV transmitting acrylic sheet ranges from 1 mm to 50 mm, covering most industrial, medical and agricultural applications. For customized items requiring thicker plates (e.g. Large-scale greenhouse panels, heavy-duty UV curing equipment windows), some manufacturers offer bespoke production up to 100 mm. However, thicker custom sheets may have longer lead times and higher costs due to the specialized manufacturing process required to maintain UV transmission uniformity.

Summarize

The choice between the UV transmitting acrylic sheet and standard acrylic board ultimately depends on a key question: Does your application need to effectively transmit UV-A or UV-B? If the answer is yes, UV transmitting acrylic sheet—as a high-performance new material—is the clear and only viable choice. Its superior UV transmission, optical uniformity, weather resistance, and mechanical stability make it indispensable for UV-reliant applications ranging from medical phototherapy to precision semiconductor manufacturing.

For applications where UV transmission is not a requirement, standard acrylic sheet remains a cost-effective and versatile option, ideal for signage, architectural glazing, and decorative goods. By understanding the main differences in performance, specifications and application applicability outlined in this guide, professionals can choose the material that best meet the technical requirements, performance objectives and budget constraints of their projects to ensure the best results and long-term reliability.

For more information about the specifications, customized formulas or specific application solutions of UV transmitting acrylic sheets, please consult the well-known manufacturer specializing in the production of optical acrylic materials. Their expertise and industry experience help to customize material according to your unique project requirements, and ensure the highest level of performance and value.

Posts Categories

- Blogs16

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2