+86 180 1040 9086

- Home

- Products

- Acrylic

- Acrylic sheet

- Clear Acrylic Sheet

- Color Acrylic Sheet

- Sanitary(Bathtub) Acrylic Sheet

- Acrylic Mirror Sheet

- Acrylic Mirror Sheet

- Aquarium Acrylic Sheet

- Day&Night Acrylic Sheet

- Fire rated Acrylic Sheet

- Frosted/Matt Acrylic Sheet

- Glitter/Fabric Acrylic Sheet

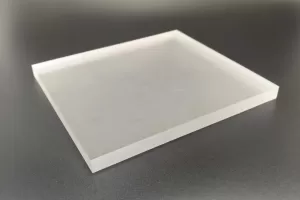

- Impact Resistant Acrylic

- Infrared Filter Acrylic

- LGP Acrylic Sheet

- Noise-Barrier Acrylic Sheet

- RV Window Acrylic Sheet

- Sign Acrylic Sheet

- Sound Barrier Fence

- Special Thick Acrylic Sheet

- UV Transmitting Acrylic

- Acrylic Tube & Rod

- Acrylic Products

- Acrylic sheet

- PVC

- Acrylic

- About Us

- Solution

- Blogs

- Contact Us

BLOG DETAILS

How to Choose Impact Resistant Acrylic Sheets for Maximum Safety and Durability?

When choosing materials for high impact applications, many professionals face a key problem: how to strike a balance between impact resistance and optical transparency? Impact resistant acrylic sheet provides an innovative solution, combining the best performance of traditional acrylic acid and polycarbonate.

The main technical advantages

Ultra high impact resistance

The biggest advantage of anti-impact acrylic is its excellent durability. Laboratory tests have confirmed that its impact strength is 5-10 times that of ordinary acrylic resin, and the measured notched impact strength of cantilever beam is ≥ 15 kJ/me (Source: ASTM D 256 standard). In the actual drop ball tests, the plate can bear the impacts of a 1 kg weight falling from a height of 1 meter without breaking. This kind of performance is close to that of polycarbonate, while maintaining excellent surface hardness.

Excellent optical Properties

Despite its enhanced durability, impact resistant acrylic maintains optical characteristics comparable to premium-grade standard acrylic. Light transmittance is 89-91%, and the haze is lower than 2%, ensuring the minimum visual distortion. The material exhibits optical distortion measurements of less than 0.5%, which makes it suitable for applications where visual clarity is critical (Source: ASTM D 1003 test protocol).

Enhance safety features

When impact-resistant acrylic resin finally breaks under extreme conditions, it will break into blunt pieces without sharp edges, thus greatly reducing the risk of injury. This fracture behavior conforms to the international safety glass standards, including ANSI Z 97.1 and CPSC 16 CFR 1201, which makes it suitable for safety glass applications.

The main application scenario

Secure and secure applications

Excellent impact resistance makes impact-resistant acrylic resin an ideal choice for safety glass displayed by financial institutions, jewelry stores and museum. In industrial environment, it can be used as a machine protection device and a security barriers around the robot workstations. Transportation applications include platform screen doors of subway stations, windows of high-speed railways, and ship applications where traditional glass would bring safety problems. According to industry data, the applications of safety glass accounts for about 35% of the consumption of high-impact plastic in commercial buildings (Source: Transparent Market Research, “Safety Glass Market Analysis in 2023”).

Buildings and public places

Architects have designated impact resistant acrylic sheet for curtain walls, skylights and stair handrails, and their requirements for safety and durability exceed those provided by standard glass. In high-traffic public areas, such as airports, gymnasiums and amusement parks, this material provides reliable protection while maintaining its beauty.

Special environment

For extreme environments, including polar research stations, desert facilities and coastal buildings, impact-resistant acrylic resins provide reliable performance when extreme temperature and environmental factors challenge traditional materials. Sports facilities use this material in skating rink guardrails, tennis court fences and swimming pool skylights, where impact resistance and safety are crucial.

Guide to processing and fabrication

Hot forming technology

Impact resistant acrylic resin can be thermoformed at 150-170 degrees Celsius. The material maintains uniform forming characteristics across its thickness range. In order to get the best results:

1. Preheat material evenly to avoid internal stresses.

2. Keep the molding temperature within the recommended range.

3. Controlled cooling is allowed to prevent warping.

Cutting and machining

This kind of material is well processed in standard numerical control equipment and laser cutting systems. As for mechanical cutting:

Use carbide-tipped tools for clean edges.

Maintain appropriate feeding speed to prevent fragmentation.

For laser cutting, CO lasers can produce the best effect under proper power settings.

Polishing technology

Edges can be polished with standard acrylic polishing methods. The material can be well accepted by printing and coating applications, and proper surface treatment ensures excellent adhesion.

Frequently asked Questions

Q:Compared with polycarbonate, what are the advantages of impact acrylic resin?

A:Although polycarbonate provides slightly higher impact resistance, impact-resistant acrylic resin provides better surface hardness, better optical transparency and enhanced ultraviolet resistance without the need for coating. The choice depends on specific application requirements, and these properties are balanced.

Q:What is the expected service life of the outdoor?

A:Properly installed impact-resistant acrylic resin usually maintains its structural and optical characteristics for 10-15 years in outdoor applications, and ultraviolet stabilizers ensure the minimum degradation from sunlight (Source: ISO 4892-2 accelerated weathering test).

Q:Can impact-resistant acrylic resin be used in contact with food?

A:Yes, a certain grades of impact resistant acrylic resin meets the requirements of the Food and Drug Administration for food contact. Verify the certificate of specific food contact use with the manufacturer.

Q:Compared with standard acrylic and polycarbonate, what is the cost?

A:The cost of impact-resistant acrylic resin is usually 20-30% higher than that of standard acrylic resin, but considering the total life cycle cost, especially in applications requiring durability and excellent optical performance, it is often more cost-effective than polycarbonate.

Industry data and performance metrics

The global market for impact-resistant plastics is projected to reach $ 12.5 billion by 2028, growing at a CAGR of 5.8% (Source: Grand View Research, “Impact-Resistant Plastics Market Report 2024”). Within this segment, impact resistant acrylic accounts for approximately 25% of architectural safety glazing applications, with adoption increasing at 7.2% annually as building codes evolve to address safety concerns . According to the performance test of ASTM E 1300 standards, it is confirmed that 12 impact-resistant acrylic board can withstand wind loads equivalent to the category 4 hurricane conditions (wind speeds of about 250km/h) under proper frame and installation. This property makes this material suitable for extreme weather applications where traditional glass has failed. Laboratory aging research shows that after 10,000 hours of accelerated weathering, the impact-resistant acrylic resin has maintained more than 85% of its original impact strength, which is equivalent to about 10 years of sunshine exposure in Florida (Source: ISO 4892-2 test protocols). This excellent durability makes it a cost-effective and long-term solution for demanding applications.

Posts Categories

- Blogs22

Product categories

- Acrylic 19

- Acrylic sheet 17

- Clear Acrylic Sheet 1

- Color Acrylic Sheet 1

- Sanitary(Bathtub Acrylic Sheet 1

- Acrylic Mirror Sheet 1

- Aquarium Acrylic Sheet 1

- Day&Night Acrylic Sheet 1

- Fire rated Acrylic Sheet 1

- Frosted/Matt Acrylic Sheet 1

- Glitter/Fabric Acrylic Sheet 1

- Impact Resistant Acrylic 1

- Infrared Filter Acrylic 1

- LGP Acrylic Sheet 1

- Noise-Barrier Acrylic Sheet 0

- RV Window Acrylic Sheet 1

- Sign Acrylic Sheet 1

- Sound Barrier Fence 1

- Special Thick Acrylic Sheet 1

- UV Transmitting Acrylic 1

- Acrylic Tube & Rod 2

- Acrylic sheet 17

- PVC 2